浙江至德鋼業有限公司技術(shu)人員,根據公司車間(jian)生產工(gong)藝及檢驗(yan)發現(xian)不銹鋼管擠壓時,使(shi)用的空(kong)心坯可(ke)以由以下三種方(fang)法(fa)獲(huo)得:

1. 在實心坯料上,直接鉆一個(ge)直徑(jing)比擠壓(ya)芯棒直徑(jing)略大的(de)孔(kong)。這種方法用于得(de)到直徑(jing)為50mm以下的(de)孔(kong)。

2. 在實心坯料(liao)上(shang),先預鉆一個直徑為20~30mm的(de)小孔,然后在擴孔機上(shang)將孔擴大到指定(ding)的(de)尺寸(cun)。這種方(fang)法用于得到50~100mm的(de)孔。

3. 實心坯料在穿(chuan)孔機上直(zhi)接穿(chuan)孔,得到所要求尺寸的孔。這種方法(fa)用于大于100mm的孔。

無論以何種方法獲得的空心坯料,其主要的質量指標是空心壞料的同心度及其內孔的彎曲度。在坯料進行穿孔或擴孔時,影響穿孔空心坯同心度和內孔看曲度的,同時也是影響其擠壓鋼管壁厚均勻度極限值的參數,主要是坯料的長度Lz,與其內孔的直徑dg的比值。一般情況下,為了確保空心坯的同心度和擠壓管壁厚均勻度的極限值,將參數L2/ds限制在一定范圍內。實心坯料穿孔時,L,/d8=5~7(碳素鋼7,不銹鋼 5~6);空心坯料擴孔時,L/dg=10~12(最大L/dg可達到15)。

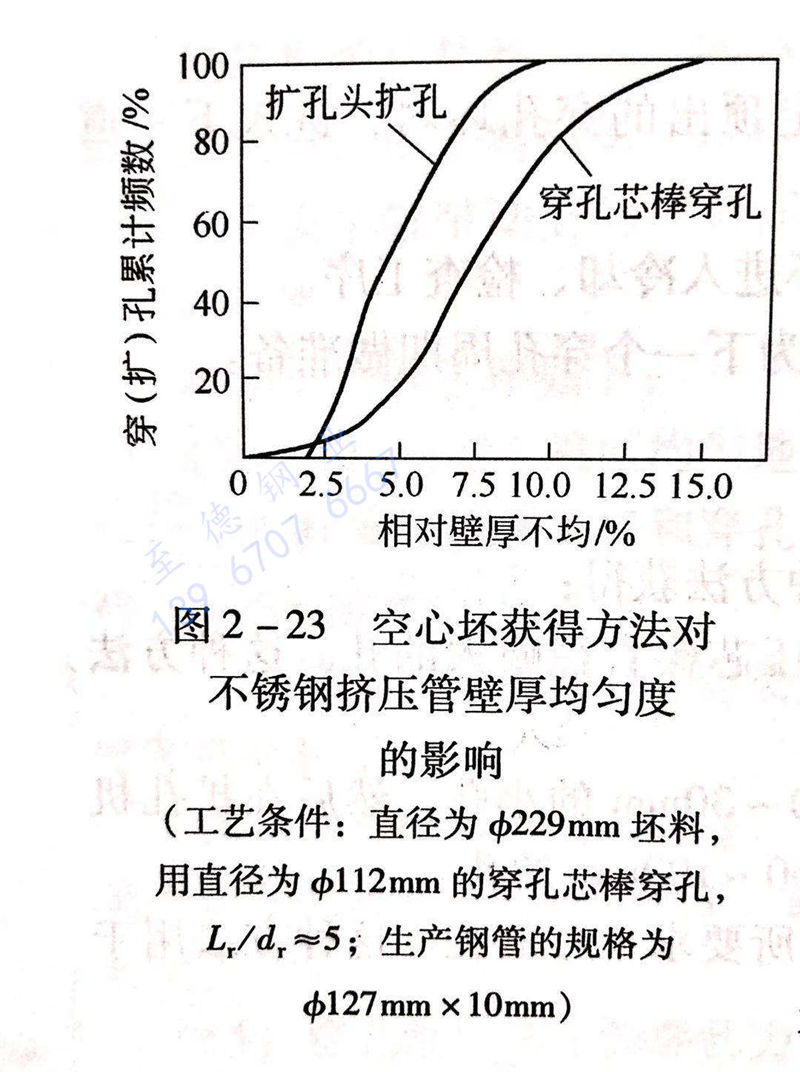

L,/d比值的選擇主要取決于材料的變形抗力以及對擠壓不銹鋼管壁厚精度的要求。06Cr18N111Ti不銹鋼坯料穿孔后空心坯壁厚不均影響的試驗結果顯示,隨著L/ds的比值從4.4增大至6.1,穿孔后空心坯的壁厚不均增大15%.根據奧地利原VEW公司在34MN擠壓機上所得到的數據,空心坯的獲得方法對不銹鋼擠壓鋼管壁厚均勻度的影響示于圖2-23。由圖2-23可知,擴孔工藝比穿孔工藝具有更高的空心坯壁厚精度。

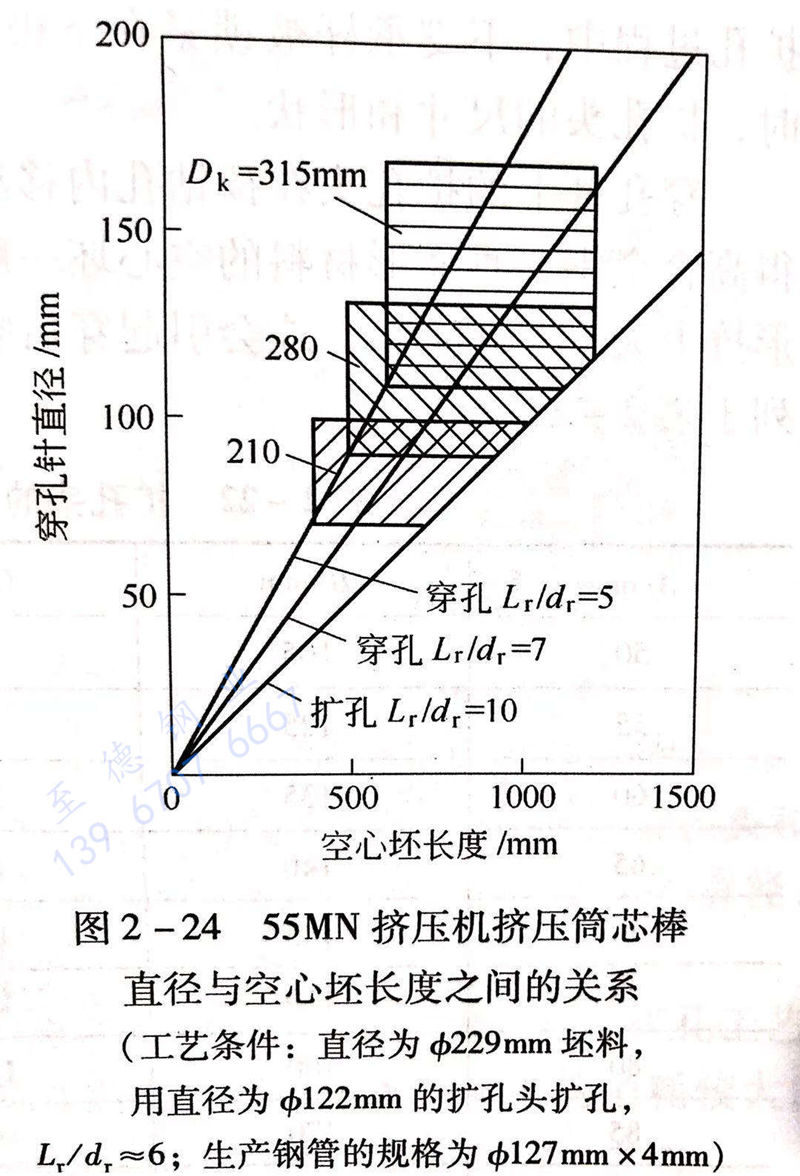

55MN擠(ji)壓(ya)機上,采(cai)用ф210mm、ф280mm和ф315mm 擠(ji)壓(ya)筒時(shi)的(de)(de)芯棒直徑空心坯(pi)長度之(zhi)間的(de)(de)關系示于圖(tu)2-24。圖(tu)中有細線的(de)(de)區域表(biao)示可能的(de)(de)芯棒直徑與空心坯(pi)的(de)(de)長度的(de)(de)比值(zhi)。采(cai)用坯(pi)料(liao)的(de)(de)孔(kong)工藝,將使這個(ge)區域向較小(xiao)的(de)(de)空心坯(pi)長度方面明顯地縮(suo)小(xiao)。在許多情(qing)況下,不銹(xiu)鋼管(guan)縮(suo)小(xiao)到一半(ban)。

不銹鋼管坯(pi)料(liao)在穿(chuan)孔和擴孔時(shi),必須滿足以下條件:在一次(ci)行程中,孔的擴大不應超過5倍;擴孔時(shi)的延伸(shen)系(xi)(xi)數(shu)不應超過1.45;穿(chuan)孔時(shi)的延伸(shen)系(xi)(xi)數(shu)不應超過1.60。

采用擴孔(kong)工(gong)(gong)藝(yi)的效果隨著穿(chuan)孔(kong)機(ji)噸位(wei)或擴孔(kong)芯(xin)棒直徑的減小而(er)(er)增(zeng)加。在(zai)這種(zhong)情況下(xia),擴孔(kong)工(gong)(gong)藝(yi)可(ke)以用到擠壓筒的整個長(chang)度擴孔(kong)頭擴孔(kong)的坯(pi)料。所(suo)以,對于10~25MN擠壓機(ji)的擠壓穿(chuan)孔(kong)芯(xin)棒穿(chuan)孔(kong)車間,立(li)式穿(chuan)(擴)孔(kong)機(ji)的選擇應(ying)該是(shi)更簡單(dan)的擴孔(kong)機(ji),而(er)(er)不是(shi)穿(chuan)孔(kong)機(ji)。

對于直徑超(chao)(chao)過150mm的(de)孔,采用(yong)擴孔工藝是不合適的(de),因為這就需要使(shi)(shi)坯料的(de)鉆孔直徑超(chao)(chao)過35mm,因而增加了(le)金屬消耗(hao),或者(zhe)是需要進行2次擴孔。其結果是使(shi)(shi)擠壓(ya)生(sheng)產線(xian)的(de)部分(fen)設備閑置(zhi),降低了(le)整條生(sheng)產線(xian)的(de)生(sheng)產的(de)影(ying)響效率。

最直接(jie)影(ying)響穿(chuan)(擴(kuo)(kuo))孔(kong)(kong)(kong)(kong)(kong)(kong)坯(pi)(pi)料(liao)(liao)同(tong)(tong)(tong)心(xin)度(du)(du)的因素是穿(chuan)(擴(kuo)(kuo))孔(kong)(kong)(kong)(kong)(kong)(kong)坯(pi)(pi)料(liao)(liao)與(yu)(yu)穿(chuan)(擴(kuo)(kuo))孔(kong)(kong)(kong)(kong)(kong)(kong)筒(tong)內(nei)(nei)襯(chen)之間(jian)(jian)的間(jian)(jian)隙(xi)(xi)。穿(chuan)孔(kong)(kong)(kong)(kong)(kong)(kong)時,由(you)于(yu)實心(xin)坯(pi)(pi)料(liao)(liao)在(zai)穿(chuan)孔(kong)(kong)(kong)(kong)(kong)(kong)筒(tong)內(nei)(nei)預(yu)先經過鐓粗(cu)(cu)(cu)工序,因此當(dang)(dang)(dang)鐓粗(cu)(cu)(cu)壞料(liao)(liao)的鐓粗(cu)(cu)(cu)變(bian)形程度(du)(du)足(zu)夠時,鐓粗(cu)(cu)(cu)后(hou)(hou)坯(pi)(pi)料(liao)(liao)與(yu)(yu)穿(chuan)孔(kong)(kong)(kong)(kong)(kong)(kong)筒(tong)內(nei)(nei)襯(chen)的牙(ya)孔(kong)(kong)(kong)(kong)(kong)(kong)和擴(kuo)(kuo)孔(kong)(kong)(kong)(kong)(kong)(kong)工藝(yi)之間(jian)(jian)的間(jian)(jian)隙(xi)(xi),基本上應等于(yu)零,在(zai)這(zhe)(zhe)種情(qing)況下,穿(chuan)孔(kong)(kong)(kong)(kong)(kong)(kong)坯(pi)(pi)料(liao)(liao)與(yu)(yu)穿(chuan)孔(kong)(kong)(kong)(kong)(kong)(kong)筒(tong)內(nei)(nei)襯(chen)之間(jian)(jian)的間(jian)(jian)隙(xi)(xi)對(dui)(dui)于(yu)穿(chuan)孔(kong)(kong)(kong)(kong)(kong)(kong)后(hou)(hou)空(kong)心(xin)坯(pi)(pi)同(tong)(tong)(tong)心(xin)度(du)(du)的影(ying)響非常小。而當(dang)(dang)(dang)擴(kuo)(kuo)孔(kong)(kong)(kong)(kong)(kong)(kong)時,由(you)于(yu)預(yu)鉆孔(kong)(kong)(kong)(kong)(kong)(kong)坯(pi)(pi)料(liao)(liao)在(zai)擴(kuo)(kuo)孔(kong)(kong)(kong)(kong)(kong)(kong)筒(tong)內(nei)(nei)不進行預(yu)先鐓粗(cu)(cu)(cu),因此,當(dang)(dang)(dang)預(yu)鉆孔(kong)(kong)(kong)(kong)(kong)(kong)坯(pi)(pi)料(liao)(liao)進行擴(kuo)(kuo)孔(kong)(kong)(kong)(kong)(kong)(kong)時,預(yu)鉆孔(kong)(kong)(kong)(kong)(kong)(kong)空(kong)心(xin)坯(pi)(pi)料(liao)(liao)外(wai)徑與(yu)(yu)擴(kuo)(kuo)孔(kong)(kong)(kong)(kong)(kong)(kong)筒(tong)內(nei)(nei)襯(chen)之間(jian)(jian)的間(jian)(jian)隙(xi)(xi)使擴(kuo)(kuo)孔(kong)(kong)(kong)(kong)(kong)(kong)過程的穩定性降低,因而直接(jie)影(ying)響到擴(kuo)(kuo)孔(kong)(kong)(kong)(kong)(kong)(kong)后(hou)(hou)空(kong)心(xin)坯(pi)(pi)的同(tong)(tong)(tong)心(xin)度(du)(du)。在(zai)擴(kuo)(kuo)孔(kong)(kong)(kong)(kong)(kong)(kong)時,對(dui)(dui)于(yu)坯(pi)(pi)料(liao)(liao)與(yu)(yu)擴(kuo)(kuo)孔(kong)(kong)(kong)(kong)(kong)(kong)筒(tong)內(nei)(nei)襯(chen)之間(jian)(jian)的間(jian)(jian)隙(xi)(xi)應當(dang)(dang)(dang)特(te)別引(yin)起注(zhu)意,并且(qie)應盡可能地(di)做到最小,且(qie)做到精確(que)。這(zhe)(zhe)是確(que)保(bao)擴(kuo)(kuo)孔(kong)(kong)(kong)(kong)(kong)(kong)后(hou)(hou)空(kong)心(xin)坯(pi)(pi)同(tong)(tong)(tong)心(xin)度(du)(du)的關(guan)鍵。

另(ling)外,有資料認為碳鋼和(he)(he)低(di)合金(jin)鋼穿(chuan)孔(kong)時的延伸系(xi)數不(bu)(bu)應大(da)于(yu)1.6,不(bu)(bu)銹鋼不(bu)(bu)應超過1.5,而擴孔(kong)時不(bu)(bu)銹鋼的延伸系(xi)數不(bu)(bu)應大(da)于(yu)1.3。圖2-23所示為空心坯(pi)獲得(de)方法對不(bu)(bu)銹鋼擠(ji)壓(ya)管(guan)(guan)(guan)壁厚均勻度(du)的影響。坯(pi)料直(zhi)徑(jing)為229mm,穿(chuan)孔(kong)芯(xin)棒和(he)(he)擴孔(kong)頭的直(zhi)徑(jing)為112mm。前者(zhe) L/d,≈5,生(sheng)產的不(bu)(bu)銹鋼管(guan)(guan)(guan)規格為 ф127mm x10mm;后者(zhe)L/d,≈6,生(sheng)產的不(bu)(bu)銹鋼管(guan)(guan)(guan)規格為ф127mmx4mm.圖2-24所示為55MN 擠(ji)壓(ya)機210mm、280mm和(he)(he)315mm擠(ji)壓(ya)筒的芯(xin)棒直(zhi)徑(jing)和(he)(he)空心坯(pi)長度(du)之(zhi)間(jian)的關系(xi)。