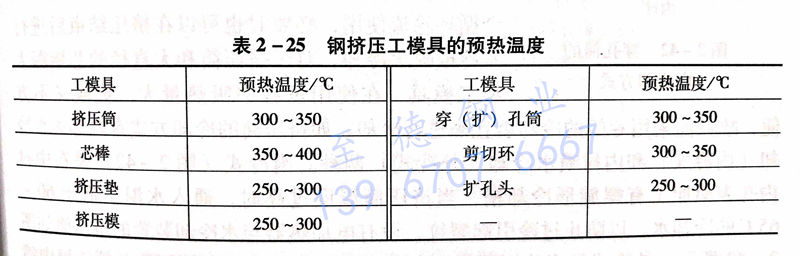

浙江至德鋼業有限公司為了減少不銹鋼(gang)管(guan)坯料與工模具接觸表面的溫降,有利于玻璃潤滑劑的軟化,提高潤滑效果,降低工模具表面熱沖擊引起的溫度應力,提高工模具的使用壽命,擠壓工模具使用前應進行預熱,其預熱溫度與擠壓材料和工模具的材質有關。擠壓不銹鋼管和型材時,工模具的預熱溫度見表2-25。

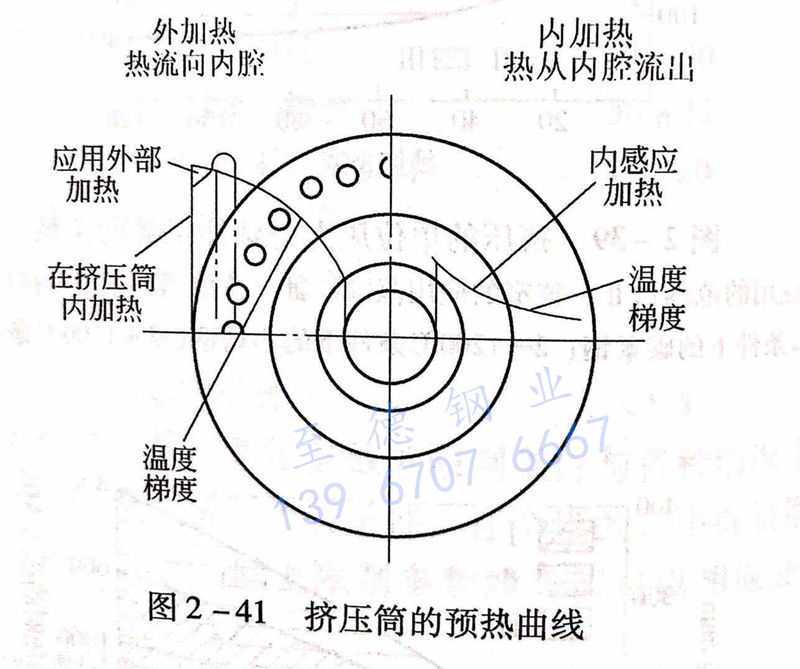

美國PMAC公司(si)的2500噸(dun)擠(ji)(ji)(ji)壓(ya)機(ji)推薦的預(yu)熱(re)(re)(re)溫度如下:工(gong)具鋼制作的擠(ji)(ji)(ji)壓(ya)模(mo)和穿孔頭為(wei)(wei)(wei)200℃,擠(ji)(ji)(ji)壓(ya)芯棒為(wei)(wei)(wei)250~320℃,擠(ji)(ji)(ji)壓(ya)筒(tong)為(wei)(wei)(wei)260~320℃,穿孔筒(tong)為(wei)(wei)(wei)360~370℃。擠(ji)(ji)(ji)壓(ya)模(mo)、擠(ji)(ji)(ji)壓(ya)墊(dian)、芯棒等小型工(gong)模(mo)具的預(yu)熱(re)(re)(re)一般采(cai)用箱式電(dian)爐。擠(ji)(ji)(ji)壓(ya)筒(tong)的預(yu)熱(re)(re)(re)主(zhu)要有電(dian)阻加(jia)(jia)熱(re)(re)(re)和感(gan)應加(jia)(jia)熱(re)(re)(re)兩(liang)種。感(gan)應加(jia)(jia)熱(re)(re)(re)是將感(gan)應線圈放入擠(ji)(ji)(ji)壓(ya)筒(tong)內(nei)(nei)(nei)進行加(jia)(jia)熱(re)(re)(re),加(jia)(jia)熱(re)(re)(re)時熱(re)(re)(re)流由內(nei)(nei)(nei)襯(chen)向外傳導,擠(ji)(ji)(ji)壓(ya)簡(jian)內(nei)(nei)(nei)的溫度分布較電(dian)阻加(jia)(jia)熱(re)(re)(re)合理(圖2-41),因(yin)為(wei)(wei)(wei)內(nei)(nei)(nei)襯(chen)、中(zhong)和外套之間的過盈配合應力不會降低,但感(gan)應加(jia)(jia)熱(re)(re)(re)時操作不便(bian),感(gan)應圈易損壞,所以目前主(zhu)要還(huan)是采(cai)用電(dian)阻加(jia)(jia)熱(re)(re)(re)。

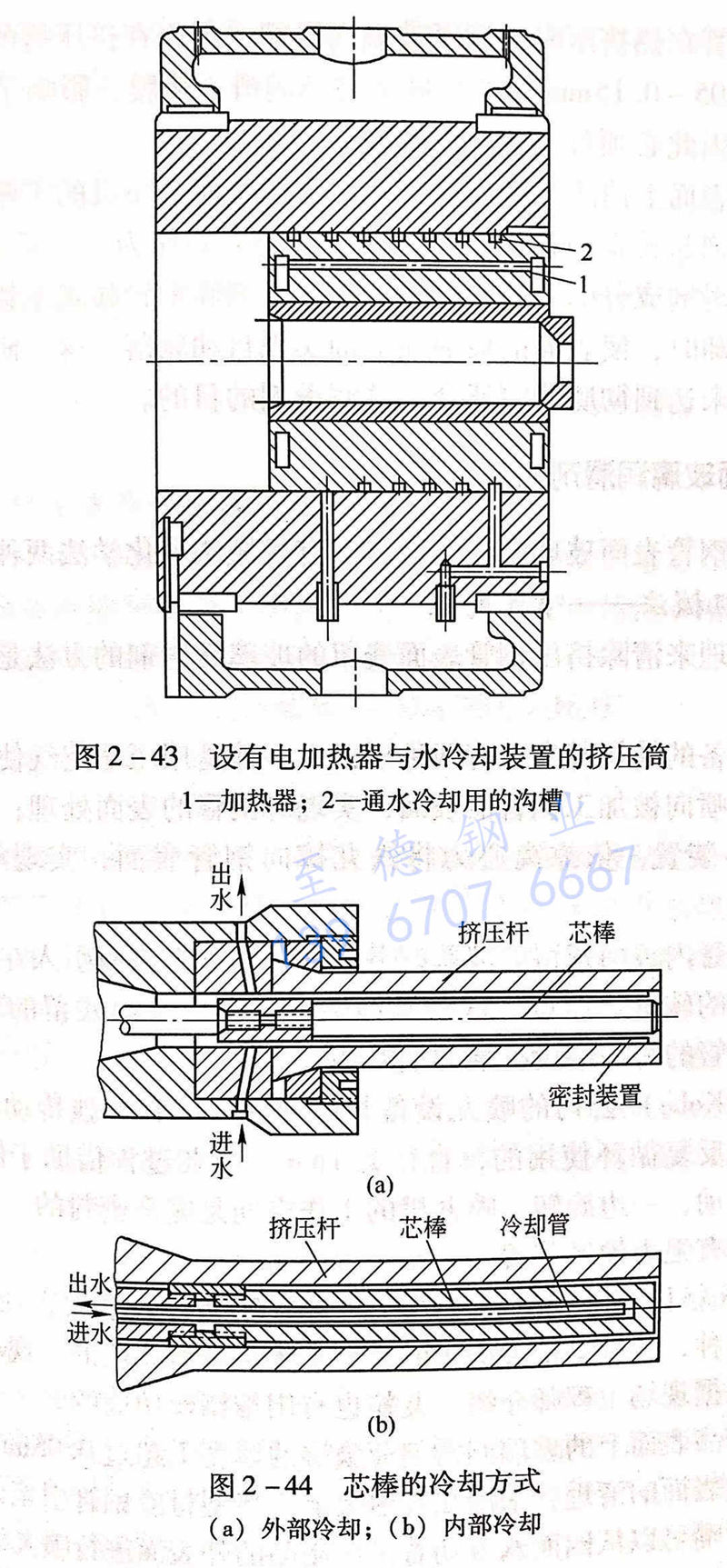

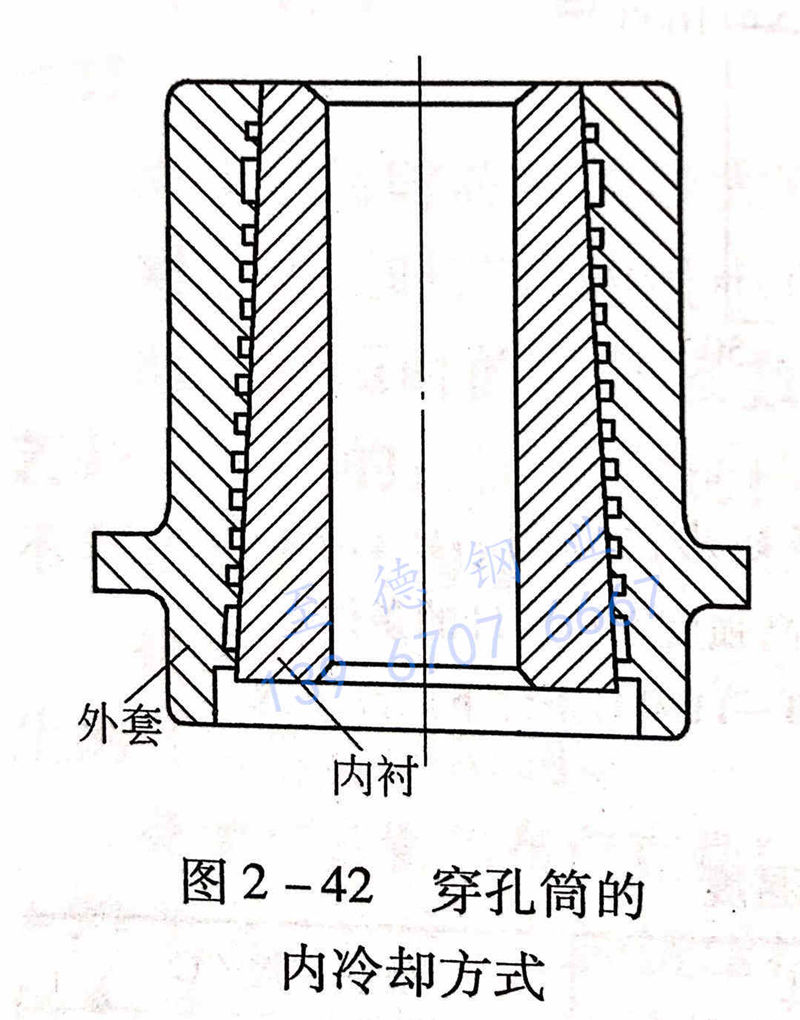

在(zai)正常擠(ji)(ji)壓(ya)(ya)(ya)(ya)(ya)(ya)生(sheng)產不銹鋼管過程(cheng)(cheng)中(zhong)(zhong),擠(ji)(ji)壓(ya)(ya)(ya)(ya)(ya)(ya)工(gong)(gong)模(mo)(mo)具(ju)連(lian)續(xu)使(shi)用(yong)(yong)時,溫(wen)度(du)將(jiang)會逐漸升高,而引(yin)起(qi)工(gong)(gong)模(mo)(mo)具(ju)材質高溫(wen)回火,降低了(le)紅硬性(xing),導致工(gong)(gong)模(mo)(mo)具(ju)產生(sheng)變形而影響擠(ji)(ji)壓(ya)(ya)(ya)(ya)(ya)(ya)過程(cheng)(cheng)的(de)(de)順利進行(xing)。如(ru)(ru)擠(ji)(ji)壓(ya)(ya)(ya)(ya)(ya)(ya)墊(dian)的(de)(de)使(shi)用(yong)(yong)溫(wen)度(du)過高,因熱(re)(re)膨脹過大(da)(da)產生(sheng)變形而引(yin)起(qi)擠(ji)(ji)壓(ya)(ya)(ya)(ya)(ya)(ya)墊(dian)卡(ka)在(zai)擠(ji)(ji)壓(ya)(ya)(ya)(ya)(ya)(ya)筒(tong)(tong)(tong)內(nei)(nei)。為此,擠(ji)(ji)壓(ya)(ya)(ya)(ya)(ya)(ya)工(gong)(gong)模(mo)(mo)具(ju)在(zai)使(shi)用(yong)(yong)過程(cheng)(cheng)中(zhong)(zhong)又(you)需要(yao)(yao)進行(xing)必要(yao)(yao)的(de)(de)冷(leng)(leng)(leng)(leng)(leng)(leng)卻(que),使(shi)其保(bao)持(chi)在(zai)所要(yao)(yao)求的(de)(de)溫(wen)度(du)范圍(wei)內(nei)(nei)工(gong)(gong)作。對(dui)于(yu)(yu)外(wai)套內(nei)(nei)襯(chen)擠(ji)(ji)壓(ya)(ya)(ya)(ya)(ya)(ya)墊(dian),擠(ji)(ji)壓(ya)(ya)(ya)(ya)(ya)(ya)模(mo)(mo)和小(xiao)直徑的(de)(de)芯(xin)棒(bang)一般(ban)可(ke)以采用(yong)(yong)3~4個循環(huan)輪流使(shi)用(yong)(yong),必要(yao)(yao)時也可(ke)以在(zai)擠(ji)(ji)壓(ya)(ya)(ya)(ya)(ya)(ya)結(jie)束(shu)后進行(xing)水(shui)(shui)(shui)(shui)(shui)冷(leng)(leng)(leng)(leng)(leng)(leng)或噴(pen)水(shui)(shui)(shui)(shui)(shui)冷(leng)(leng)(leng)(leng)(leng)(leng)卻(que)。對(dui)于(yu)(yu)擠(ji)(ji)壓(ya)(ya)(ya)(ya)(ya)(ya)筒(tong)(tong)(tong)和大(da)(da)直徑的(de)(de)芯(xin)棒(bang)等大(da)(da)型工(gong)(gong)模(mo)(mo)具(ju),在(zai)使(shi)用(yong)(yong)過程(cheng)(cheng)中(zhong)(zhong)吸熱(re)(re)量大(da)(da),更換(huan)又(you)不方便,故只(zhi)能(neng)(neng)采用(yong)(yong)專門的(de)(de)冷(leng)(leng)(leng)(leng)(leng)(leng)卻(que)裝(zhuang)(zhuang)置來進行(xing)冷(leng)(leng)(leng)(leng)(leng)(leng)卻(que)。如(ru)(ru)擠(ji)(ji)壓(ya)(ya)(ya)(ya)(ya)(ya)筒(tong)(tong)(tong)的(de)(de)冷(leng)(leng)(leng)(leng)(leng)(leng)卻(que)方式有(you)內(nei)(nei)部(bu)通(tong)水(shui)(shui)(shui)(shui)(shui)冷(leng)(leng)(leng)(leng)(leng)(leng)卻(que)(內(nei)(nei)冷(leng)(leng)(leng)(leng)(leng)(leng)式)和內(nei)(nei)襯(chen)噴(pen)水(shui)(shui)(shui)(shui)(shui)冷(leng)(leng)(leng)(leng)(leng)(leng)卻(que)(外(wai)冷(leng)(leng)(leng)(leng)(leng)(leng)式)兩(liang)種(zhong)。內(nei)(nei)冷(leng)(leng)(leng)(leng)(leng)(leng)式(圖2-42)是在(zai)中(zhong)(zhong)襯(chen)內(nei)(nei)孔表面加工(gong)(gong)有(you)螺旋形冷(leng)(leng)(leng)(leng)(leng)(leng)卻(que)槽,當擠(ji)(ji)壓(ya)(ya)(ya)(ya)(ya)(ya)筒(tong)(tong)(tong)溫(wen)度(du)過高時,通(tong)入水(shui)(shui)(shui)(shui)(shui)溫(wen)不低于(yu)(yu)60~65℃的(de)(de)冷(leng)(leng)(leng)(leng)(leng)(leng)卻(que)水(shui)(shui)(shui)(shui)(shui),以防止過冷(leng)(leng)(leng)(leng)(leng)(leng)引(yin)起(qi)裂紋,設(she)有(you)電加熱(re)(re)器與水(shui)(shui)(shui)(shui)(shui)冷(leng)(leng)(leng)(leng)(leng)(leng)卻(que)裝(zhuang)(zhuang)置的(de)(de)擠(ji)(ji)壓(ya)(ya)(ya)(ya)(ya)(ya)筒(tong)(tong)(tong),如(ru)(ru)圖2-43所示;外(wai)冷(leng)(leng)(leng)(leng)(leng)(leng)式是當擠(ji)(ji)壓(ya)(ya)(ya)(ya)(ya)(ya)循環(huan)結(jie)束(shu)時,采用(yong)(yong)環(huan)狀噴(pen)嘴在(zai)擠(ji)(ji)壓(ya)(ya)(ya)(ya)(ya)(ya)筒(tong)(tong)(tong)一端向筒(tong)(tong)(tong)內(nei)(nei)噴(pen)入壓(ya)(ya)(ya)(ya)(ya)(ya)力水(shui)(shui)(shui)(shui)(shui)冷(leng)(leng)(leng)(leng)(leng)(leng)卻(que),這種(zhong)方法比較(jiao)簡單,但內(nei)(nei)襯(chen)的(de)(de)材質要(yao)(yao)具(ju)有(you)良好(hao)的(de)(de)耐急(ji)(ji)冷(leng)(leng)(leng)(leng)(leng)(leng)急(ji)(ji)熱(re)(re)性(xing)能(neng)(neng)。擠(ji)(ji)壓(ya)(ya)(ya)(ya)(ya)(ya)芯(xin)棒(bang)的(de)(de)冷(leng)(leng)(leng)(leng)(leng)(leng)卻(que)也有(you)內(nei)(nei)冷(leng)(leng)(leng)(leng)(leng)(leng)式和外(wai)冷(leng)(leng)(leng)(leng)(leng)(leng)式兩(liang)種(zhong)(圖2-44)。