不銹鋼化學著色配方 20 (見表8-9) ,本配(pei)方(fang)由沈陽工業學(xue)院金光、張學(xue)萍、畢監智于2004年提出。

他們通過正交試驗研究了不銹鋼著色液配方、溫度、時間、電極電位對著色的影響,優化著色工藝,獲得電極電位與顏色的良好對應關系,測試了著色膜的耐磨性,耐蝕性、變形加工性能,分析添加劑對不銹鋼著色的影響。所得膜層顏色均勻,耐磨性、耐蝕性、變形加工性能良好,工藝維護簡單。

1. 實驗工藝流程(cheng)

304不銹(xiu)鋼(鏡面光亮8K)→清洗→堿性除油→水洗→酸活化→著色→硬化(鉻酐250g/L,濃硫酸1.4mL/L,DK0.5~1.0A/d㎡,溫度45~55℃,時間10~15min)→水洗→封閉(Na2SiO3 10g/L,溫度沸騰,時間10~15min)→水洗→干燥。

2. 實驗(yan)結(jie)果(guo)

①. 溫度(du)

50℃時加入較多添加劑,反應速(su)率平穩,著色膜色澤(ze)均勻(yun),鮮艷度好。

60℃時添(tian)加劑(ji)含量對結果影響不大,膜層(ceng)質量好。

100℃時溫度高(gao),使反應速(su)率過快,著(zhu)色膜色澤(ze)不(bu)均勻,不(bu)易控制。

②. 表面(mian)膜的電極電位(wei)與(yu)顏色的對應關系

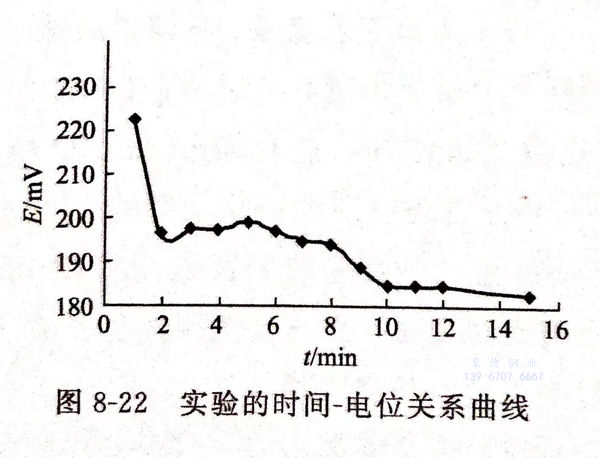

著色時(shi)(shi),開始電(dian)(dian)(dian)(dian)(dian)位(wei)(wei)(wei)很高(gao),而(er)后迅速下降,之后逐步上(shang)升,到達一個(ge)(ge)高(gao)點電(dian)(dian)(dian)(dian)(dian)位(wei)(wei)(wei)后再下降。這(zhe)個(ge)(ge)高(gao)點電(dian)(dian)(dian)(dian)(dian)位(wei)(wei)(wei)為著上(shang)顏色的(de)(de)(de)起始電(dian)(dian)(dian)(dian)(dian)極(ji)電(dian)(dian)(dian)(dian)(dian)位(wei)(wei)(wei)。圖(tu)8-22為不銹鋼(gang)片對(dui)鉑片的(de)(de)(de)電(dian)(dian)(dian)(dian)(dian)極(ji)電(dian)(dian)(dian)(dian)(dian)位(wei)(wei)(wei)與時(shi)(shi)間的(de)(de)(de)關系曲線。著色時(shi)(shi),每(mei)隔(ge)1min用(yong)數字(zi)萬(wan)用(yong)表記錄下不銹鋼(gang)片對(dui)鉑片的(de)(de)(de)電(dian)(dian)(dian)(dian)(dian)極(ji)電(dian)(dian)(dian)(dian)(dian)位(wei)(wei)(wei),著色時(shi)(shi)間5min,199mV,變(bian)成(cheng)(cheng)黑(hei)(hei)色的(de)(de)(de)電(dian)(dian)(dian)(dian)(dian)位(wei)(wei)(wei)是(shi)(shi)189mV,變(bian)成(cheng)(cheng)藍色的(de)(de)(de)電(dian)(dian)(dian)(dian)(dian)位(wei)(wei)(wei)是(shi)(shi)187mV,變(bian)成(cheng)(cheng)黃色的(de)(de)(de)電(dian)(dian)(dian)(dian)(dian)位(wei)(wei)(wei)是(shi)(shi)185mV,變(bian)成(cheng)(cheng)金黃色的(de)(de)(de)電(dian)(dian)(dian)(dian)(dian)位(wei)(wei)(wei)是(shi)(shi)183mV,所以,黑(hei)(hei)色的(de)(de)(de)電(dian)(dian)(dian)(dian)(dian)位(wei)(wei)(wei)差(cha)是(shi)(shi)10mV,藍色的(de)(de)(de)電(dian)(dian)(dian)(dian)(dian)位(wei)(wei)(wei)差(cha)是(shi)(shi)12mV,黃色的(de)(de)(de)電(dian)(dian)(dian)(dian)(dian)位(wei)(wei)(wei)差(cha)是(shi)(shi)14mV,金黃色的(de)(de)(de)電(dian)(dian)(dian)(dian)(dian)位(wei)(wei)(wei)差(cha)是(shi)(shi)16mV。

③. 前處理對著色的影響

化學除油(you)時,著色面應充分(fen)被水所潤濕(shi),否則(ze)結合力欠佳或發花,甚至著不上(shang)色。

活化(hua)是(shi)為了消(xiao)除不銹鋼(gang)表面的(de)(de)鈍(dun)化(hua)膜,獲得(de)新鮮表面。活化(hua)不足,著(zhu)色(se)的(de)(de)起始電位保(bao)持時間長,顏色(se)不容易控制,活化(hua)過度則使著(zhu)色(se)膜暗淡(dan)無光。

④. 后處理的影響

著色(se)(se)膜形(xing)成后(hou)存在大量(liang)微細(xi)孔,腹層疏松不牢固,易磨(mo)損(sun),必(bi)須硬化處理(li)。硬化處理(li)后(hou)防止表(biao)面被污染,需封閉處理(li)。封閉煮沸(fei)時(shi)間以15~20min為佳(jia)。時(shi)間過短,耐磨(mo)性不佳(jia),過長(chang)形(xing)成色(se)(se)斑,顏色(se)(se)深度下降。

⑤. 添加劑(ji)的影響

適當加(jia)入少量鉬(mu)酸銨有利于封閉后著色膜的耐磨性提高(gao),會加(jia)速著色膜中微孔的充填(tian)效果(guo)。碳酸鹽(yan)和硫酸鹽(yan)加(jia)快著色速率。

⑥. 攪拌的影響

攪(jiao)拌著色(se)(se)液的著色(se)(se)膜(mo)色(se)(se)彩均(jun)勻性明(ming)顯(xian)優于(yu)不攪(jiao)拌的著色(se)(se)液。

3. 著色(se)膜層性(xing)能(neng)實驗

①. 耐(nai)蝕性(xing)

著色(se)試片(pian)放入20%硫酸中,48小時未發生(sheng)腐蝕。未著色(se)試片(pian)很快(kuai)被(bei)腐蝕。

②. 耐磨(mo)性

用橡皮(pi)反復(fu)擦拭著(zhu)色面300次,沒有發現起(qi)皮(pi)現象,說明耐磨性很好(hao)。

③. 加工性能

彎(wan)曲(qu)180°,著色膜沒有脫(tuo)落(luo)。說明具有良(liang)好的機械加工性(xing)能(neng)。