電弧在焊劑層下燃燒進行焊接的方法稱為埋弧焊(han)(submerged arc welding,SAW)。焊接電弧在焊絲與焊件之間燃燒,焊絲沿著待焊軌跡均勻不斷地送往電弧區,電弧熱將焊絲端部及電弧附近的母材金屬和焊劑熔化,電弧移開后熔池金屬凝固成焊縫,熔化的焊劑(未滲入焊縫金屬中的那部分)則凝固成渣殼覆蓋于焊縫表面。埋弧焊分機械操作(自動)和手工操作(半自動)兩種方法。

不銹鋼管埋弧焊(han)設(she)備按(an)送(song)絲(si)機(ji)構(gou)可分為等速送(song)絲(si)和均勻調節送(song)絲(si)兩大類。

1. 等(deng)速送絲(又(you)稱電弧自(zi)身調節(jie)送絲)

等(deng)速(su)送(song)絲適用于細焊(han)(han)(han)絲或高電(dian)(dian)(dian)(dian)流密度的焊(han)(han)(han)接(jie)(jie)(jie)(jie)場合,配合管(guan)狀導(dao)(dao)電(dian)(dian)(dian)(dian)嘴(zui)(zui)(或稱管(guan)狀偏心(xin)導(dao)(dao)電(dian)(dian)(dian)(dian)嘴(zui)(zui)、偏心(xin)導(dao)(dao)電(dian)(dian)(dian)(dian)嘴(zui)(zui))。焊(han)(han)(han)絲的送(song)進(jin)按(an)預選定的速(su)度等(deng)速(su)進(jin)入焊(han)(han)(han)接(jie)(jie)(jie)(jie)區,其工作原(yuan)理(li)是(shi)采用機械方法(更換(huan)變(bian)(bian)速(su)齒(chi)輪)來(lai)調速(su)。依靠電(dian)(dian)(dian)(dian)弧的自身調節作用來(lai)維持弧長相對穩定。當焊(han)(han)(han)接(jie)(jie)(jie)(jie)電(dian)(dian)(dian)(dian)弧受(shou)到外界干擾(rao)而弧長增加時(shi),下(xia)降外特性電(dian)(dian)(dian)(dian)源供給的焊(han)(han)(han)接(jie)(jie)(jie)(jie)電(dian)(dian)(dian)(dian)流減小,焊(han)(han)(han)絲熔(rong)(rong)化速(su)度減緩(huan),電(dian)(dian)(dian)(dian)弧便會由長變(bian)(bian)短,趨向(xiang)給定值。反之,電(dian)(dian)(dian)(dian)弧變(bian)(bian)短時(shi),焊(han)(han)(han)接(jie)(jie)(jie)(jie)電(dian)(dian)(dian)(dian)流增大,焊(han)(han)(han)絲熔(rong)(rong)化加快,弧長又由短變(bian)(bian)長,趨向(xiang)給定值。按(an)這個工作原(yuan)理(li)制造的等(deng)速(su)送(song)絲埋弧焊(han)(han)(han)設備有MZ1-1000、MZ2-1500和MZ3-500等(deng)型號,其焊(han)(han)(han)接(jie)(jie)(jie)(jie)電(dian)(dian)(dian)(dian)源可采用交流、直流弧焊(han)(han)(han)電(dian)(dian)(dian)(dian)源。

2. 均勻調(diao)節(jie)送(song)絲(又稱強(qiang)迫調(diao)節(jie)送(song)絲、變速送(song)絲)

均(jun)勻調(diao)節(jie)送絲適用于粗焊絲或(huo)低電流密度的焊接場合,配合滾(gun)輪式或(huo)夾瓦式導電嘴。

焊(han)絲的送進速(su)度(du)(du)按電(dian)(dian)弧(hu)(hu)電(dian)(dian)壓的高(gao)低自動(dong)均(jun)勻調(diao)節,電(dian)(dian)弧(hu)(hu)電(dian)(dian)壓調(diao)節原(yuan)理是利用(yong)電(dian)(dian)弧(hu)(hu)電(dian)(dian)壓作為反(fan)饋信(xin)號(hao),經過(guo)控(kong)制(zhi)(zhi)調(diao)節系統改變送絲速(su)度(du)(du)而保持弧(hu)(hu)長(chang)(chang)相(xiang)對(dui)不變。當電(dian)(dian)弧(hu)(hu)受外界干擾(rao)變長(chang)(chang),電(dian)(dian)弧(hu)(hu)電(dian)(dian)壓升(sheng)高(gao)時,控(kong)制(zhi)(zhi)調(diao)節系統接到(dao)電(dian)(dian)壓反(fan)饋信(xin)號(hao)后送絲速(su)度(du)(du)調(diao)快(kuai),弧(hu)(hu)長(chang)(chang)由(you)長(chang)(chang)變短,趨向(xiang)穩定值。當電(dian)(dian)弧(hu)(hu)長(chang)(chang)度(du)(du)變短,電(dian)(dian)弧(hu)(hu)電(dian)(dian)壓下(xia)降時,將送絲速(su)度(du)(du)調(diao)慢,弧(hu)(hu)長(chang)(chang)增長(chang)(chang)趨向(xiang)給定值。這種埋弧(hu)(hu)焊(han)機的控(kong)制(zhi)(zhi)系統稍(shao)復雜,具體型號(hao)有(you)MZ-1000、MZ-1-1000和(he)MU1-1000等(deng)。其焊(han)接電(dian)(dian)源可采(cai)用(yong)交流、直流弧(hu)(hu)焊(han)電(dian)(dian)源。

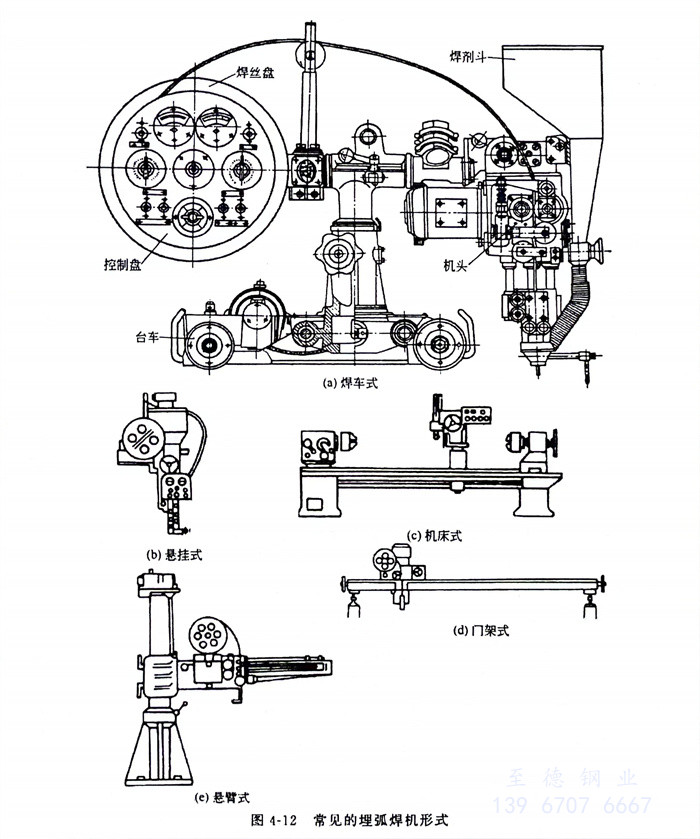

按工(gong)作需要,埋(mai)弧焊機常見(jian)的構造形式(shi)有(you):焊車(che)式(shi)、懸(xuan)掛式(shi)、機床(chuang)式(shi)、門架(jia)式(shi)和(he)懸(xuan)臂式(shi)等,如圖4-12所示。