不銹鋼管(guan)擠(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)時(shi)(shi),擠(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)墊(dian)(dian)(dian)置于坯料和擠(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)桿(gan)之間(jian),起著保護擠(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)桿(gan)的(de)(de)作用(yong),使擠(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)桿(gan)不與(yu)高(gao)溫(wen)坯料直(zhi)接(jie)接(jie)觸,以免擠(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)桿(gan)受到(dao)高(gao)溫(wen)坯料的(de)(de)熱影響。并且,擠(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)墊(dian)(dian)(dian)和擠(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)筒及擠(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)芯(xin)棒之間(jian)的(de)(de)精確配合(he),減輕了擠(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)桿(gan)前(qian)進時(shi)(shi)的(de)(de)摩擦力和磨損,同時(shi)(shi)也防(fang)止了金屬黏結在擠(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)桿(gan)上,使擠(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)墊(dian)(dian)(dian)和壓(ya)(ya)(ya)余的(de)(de)分離更加容易進行。

在不銹鋼管擠壓過程中,擠壓墊承受高的壓縮應力,受到強烈的熱作用,使擠壓墊的工作溫度達到600~800℃.

當擠壓墊在擠壓筒中移動時,擠壓墊的側表面由于滑動的結果而發生摩擦,擠壓墊的前端面和側表面的邊緣受到最強烈的高溫加熱。在擠壓的結束階段,擠壓墊側面的尖銳邊緣磨損特別明顯,并且,在擠壓墊的前端面也發生磨損。當擠壓墊側面尖銳邊緣發生變形,不銹鋼管進入擠壓筒和擠壓墊的間隙中,楔住擠壓墊,擠壓墊再向擠壓金屬的變形區移動并陷入金屬變形錐“死區”內時,將進一步加劇擠壓墊邊緣的損壞。因此,一般都將擠壓墊的邊緣做成帶有一定曲率半徑的圓弧形狀。而擠壓墊前端平面的磨損,一般與坯料金屬外層沿擠壓墊從邊緣向中心的流動的溫度和速度條件有關。

1. 擠壓墊的種類(lei)和結構形(xing)式

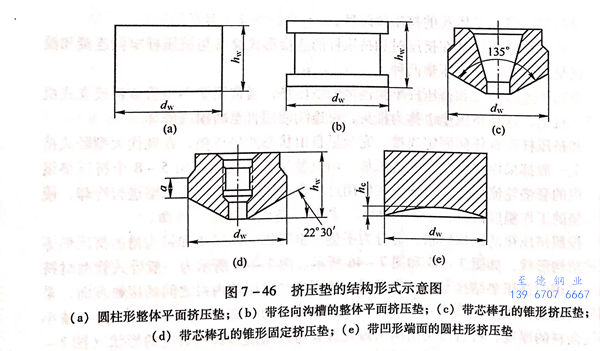

擠(ji)壓(ya)墊(dian)的(de)結構(gou)主要有在擠(ji)壓(ya)實心型材(cai)時(shi)用的(de)整體型擠(ji)壓(ya)墊(dian)和(he)在擠(ji)壓(ya)鋼(gang)管及空心型材(cai)時(shi)用的(de)帶(dai)有芯棒孔的(de)擠(ji)壓(ya)墊(dian)兩種。

另外,擠(ji)(ji)(ji)壓(ya)(ya)墊按其在擠(ji)(ji)(ji)壓(ya)(ya)時和擠(ji)(ji)(ji)壓(ya)(ya)桿(gan)的連(lian)接(jie)形式又有與(yu)擠(ji)(ji)(ji)壓(ya)(ya)桿(gan)牢固連(lian)接(jie)和沒有連(lian)接(jie)呈(cheng)自由狀態的擠(ji)(ji)(ji)壓(ya)(ya)墊兩種。

借(jie)助于(yu)連(lian)(lian)接(jie)螺(luo)紋和擠壓(ya)桿牢固(gu)連(lian)(lian)接(jie)的擠壓(ya)墊,通常用于(yu)小(xiao)型擠壓(ya)機或(huo)立式機械擠壓(ya)機上(shang)。這(zhe)種擠壓(ya)墊也稱為桿頭,可連(lian)(lian)續使用直至磨損或(huo)破(po)壞。

和擠(ji)壓(ya)桿沒(mei)有任(ren)何固定連(lian)接,完全呈(cheng)自由(you)狀態的擠(ji)壓(ya)墊,在現(xian)代大(da)型(xing)臥式擠(ji)壓(ya)機(ji)上一(yi)般都(dou)采(cai)(cai)用(yong)這種類型(xing)的擠(ji)壓(ya)墊。而且使(shi)用(yong)時往(wang)往(wang)采(cai)(cai)用(yong)由(you)5~8個擠(ji)壓(ya)墊組成一(yi)組的套墊輪流使(shi)用(yong)。這樣(yang),在使(shi)用(yong)過程中可以通過空氣(qi)或水(shui)浴(yu)進(jin)行冷卻,使(shi)擠(ji)壓(ya)墊的工作溫度(du)保持在150~200℃.提高了(le)擠(ji)壓(ya)墊的使(shi)用(yong)壽命。

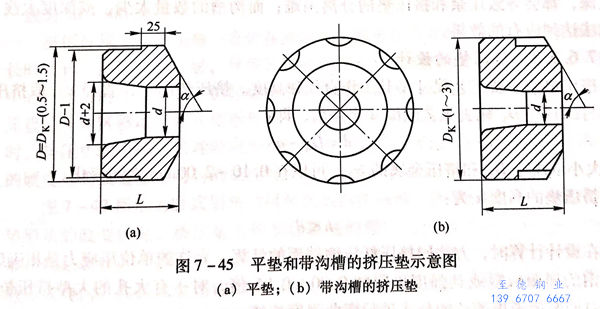

按照擠(ji)(ji)壓(ya)(ya)(ya)(ya)墊(dian)(dian)(dian)(dian)(dian)的(de)(de)(de)結(jie)構形(xing)狀(zhuang),可分為平墊(dian)(dian)(dian)(dian)(dian)、錐形(xing)墊(dian)(dian)(dian)(dian)(dian)、凹形(xing)墊(dian)(dian)(dian)(dian)(dian)和帶溝槽的(de)(de)(de)擠(ji)(ji)壓(ya)(ya)(ya)(ya)墊(dian)(dian)(dian)(dian)(dian)等五種結(jie)構形(xing)狀(zhuang),如圖7-45和圖7-46所(suo)示。圖7-46所(suo)示為一(yi)般(ban)臥式管型材擠(ji)(ji)壓(ya)(ya)(ya)(ya)機采(cai)(cai)用的(de)(de)(de)擠(ji)(ji)壓(ya)(ya)(ya)(ya)墊(dian)(dian)(dian)(dian)(dian)結(jie)構形(xing)式。為了(le)減小(xiao)擠(ji)(ji)壓(ya)(ya)(ya)(ya)墊(dian)(dian)(dian)(dian)(dian)與(yu)(yu)擠(ji)(ji)壓(ya)(ya)(ya)(ya)筒內襯之間的(de)(de)(de)接觸表面(mian),采(cai)(cai)用帶溝槽的(de)(de)(de)擠(ji)(ji)壓(ya)(ya)(ya)(ya)墊(dian)(dian)(dian)(dian)(dian)(圖7-46(b)、圖7-46(c)、圖7-46(d));為了(le)減小(xiao)擠(ji)(ji)壓(ya)(ya)(ya)(ya)余料的(de)(de)(de)厚度(du),將擠(ji)(ji)壓(ya)(ya)(ya)(ya)墊(dian)(dian)(dian)(dian)(dian)前端(duan)面(mian)做成具有與(yu)(yu)擠(ji)(ji)壓(ya)(ya)(ya)(ya)模形(xing)狀(zhuang)相適應的(de)(de)(de)形(xing)狀(zhuang)(圖7-46(c)、圖7-46(d))的(de)(de)(de)錐形(xing)墊(dian)(dian)(dian)(dian)(dian);在要求實現沒有擠(ji)(ji)壓(ya)(ya)(ya)(ya)縮(suo)尾的(de)(de)(de)條件下,采(cai)(cai)用帶有凸形(xing)端(duan)面(mian)的(de)(de)(de)擠(ji)(ji)壓(ya)(ya)(ya)(ya)墊(dian)(dian)(dian)(dian)(dian)(圖7-46(b)、圖7-46(e));為了(le)防止在切(qie)壓(ya)(ya)(ya)(ya)余前,擠(ji)(ji)壓(ya)(ya)(ya)(ya)墊(dian)(dian)(dian)(dian)(dian)和壓(ya)(ya)(ya)(ya)余過早分離,采(cai)(cai)用圓周(zhou)刻槽的(de)(de)(de)擠(ji)(ji)壓(ya)(ya)(ya)(ya)墊(dian)(dian)(dian)(dian)(dian)(圖7-45(b)).

帶有(you)溝(gou)槽(cao)的(de)(de)(de)(de)擠(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)(ya)墊(dian)除了(le)避免高(gao)溫坯料對于(yu)擠(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)(ya)桿(gan)(gan)的(de)(de)(de)(de)熱作用,以及與擠(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)(ya)筒、擠(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)(ya)芯棒的(de)(de)(de)(de)緊(jin)密(mi)配合(he),降(jiang)低了(le)擠(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)(ya)桿(gan)(gan)對擠(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)(ya)筒內壁的(de)(de)(de)(de)摩擦力,減小了(le)擠(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)(ya)桿(gan)(gan)的(de)(de)(de)(de)磨(mo)損(sun),并(bing)(bing)防(fang)止壓(ya)(ya)(ya)(ya)余(yu)(yu)黏在(zai)擠(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)(ya)桿(gan)(gan)上之(zhi)外(wai),更主要的(de)(de)(de)(de)是在(zai)自(zi)(zi)(zi)動(dong)化控制(zhi)的(de)(de)(de)(de)擠(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)(ya)機上,防(fang)止壓(ya)(ya)(ya)(ya)余(yu)(yu)和(he)擠(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)(ya)墊(dian)過早地自(zi)(zi)(zi)動(dong)分離,而使擠(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)(ya)結束后壓(ya)(ya)(ya)(ya)余(yu)(yu)緊(jin)貼在(zai)擠(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)(ya)模(mo)座上,導致(zhi)當擠(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)(ya)筒回程50m時,無法帶離壓(ya)(ya)(ya)(ya)余(yu)(yu)并(bing)(bing)為壓(ya)(ya)(ya)(ya)余(yu)(yu)的(de)(de)(de)(de)鋸(ju)切(qie)留(liu)出下鋸(ju)的(de)(de)(de)(de)空(kong)間,而影響到擠(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)(ya)機自(zi)(zi)(zi)動(dong)化操作的(de)(de)(de)(de)連續進(jin)行。采用帶溝(gou)槽(cao)的(de)(de)(de)(de)擠(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)(ya)墊(dian),能有(you)效地防(fang)止壓(ya)(ya)(ya)(ya)余(yu)(yu)和(he)擠(ji)(ji)(ji)(ji)壓(ya)(ya)(ya)(ya)墊(dian)的(de)(de)(de)(de)過早分離。

在設計帶溝槽(cao)的(de)擠壓(ya)墊時,溝槽(cao)的(de)深(shen)度和個數應(ying)適當。溝槽(cao)的(de)個數太(tai)多(duo)和深(shen)度太(tai)深(shen),都會導致壓(ya)余和擠壓(ya)墊的(de)分(fen)離困難;而溝槽(cao)的(de)數量太(tai)少(shao),或深(shen)度太(tai)淺,則無法(fa)達到應(ying)有的(de)效果(guo)。

2. 擠壓墊(dian)的設計(ji)

擠(ji)壓墊的主(zhu)要工藝(yi)尺寸(cun)是其工作(zuo)(zuo)直徑和(he)高度(du)。擠(ji)壓墊的工作(zuo)(zuo)直徑d,取(qu)擠(ji)壓筒內襯的直徑Dk減去工藝(yi)間隙a之差值,即: d=Dk-a

a 的大小取決于Dk和擠壓金屬的σt,可以在0.10~2.00mm之間變化。

擠壓墊的(de)高度(du)h為: h≤d

在設計(ji)(ji)計(ji)(ji)算(suan)時,方法同(tong)擠(ji)(ji)壓桿壓縮端面的(de)計(ji)(ji)算(suan)。允(yun)許的(de)單位壓應力是相應熱(re)強度鋼的(de)屈服極限或(huo)其強度極限的(de)0.90~0.95倍,對(dui)于(yu)有大孔的(de)大型擠(ji)(ji)壓墊,計(ji)(ji)算(suan)時同(tong)時要(yao)考慮薄片的(de)公(gong)式進(jin)行彎(wan)曲強度校核。

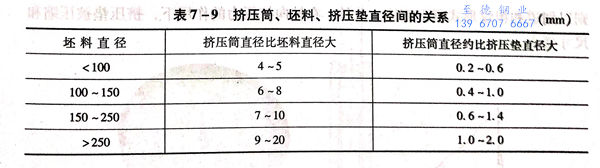

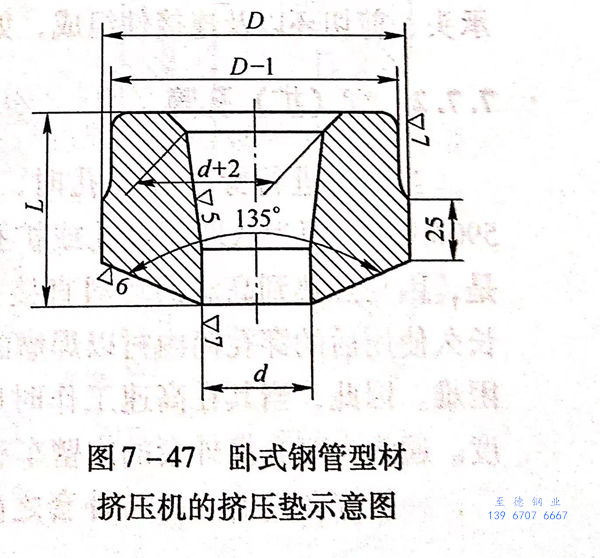

根據經驗,擠(ji)(ji)(ji)(ji)壓(ya)(ya)墊(dian)(dian)(dian)(dian)的(de)尺寸可根據擠(ji)(ji)(ji)(ji)壓(ya)(ya)筒(tong)(tong)和(he)芯棒來決定。擠(ji)(ji)(ji)(ji)壓(ya)(ya)墊(dian)(dian)(dian)(dian)和(he)擠(ji)(ji)(ji)(ji)壓(ya)(ya)筒(tong)(tong)之(zhi)間的(de)間隙(xi)取(qu)(qu)0.5~1.5mm;擠(ji)(ji)(ji)(ji)壓(ya)(ya)墊(dian)(dian)(dian)(dian)和(he)芯棒之(zhi)間的(de)間隙(xi)取(qu)(qu)0.5~2.0mm,盡(jin)可能取(qu)(qu)小值,這是保證鋼管壁厚均勻的(de)措施之(zhi)一(yi),但間隙(xi)太小或配(pei)合不(bu)當,會引起“卡(ka)墊(dian)(dian)(dian)(dian)”現象;擠(ji)(ji)(ji)(ji)壓(ya)(ya)墊(dian)(dian)(dian)(dian)的(de)厚度(du)(du)一(yi)般(ban)取(qu)(qu)50~120mm,約(yue)為擠(ji)(ji)(ji)(ji)壓(ya)(ya)筒(tong)(tong)直徑(jing)的(de)三(san)分(fen)之(zhi)一(yi);擠(ji)(ji)(ji)(ji)壓(ya)(ya)墊(dian)(dian)(dian)(dian)兩端平(ping)面必(bi)須平(ping)行;擠(ji)(ji)(ji)(ji)壓(ya)(ya)墊(dian)(dian)(dian)(dian)應(ying)耐磨,硬度(du)(du)HRC為48~52.擠(ji)(ji)(ji)(ji)壓(ya)(ya)筒(tong)(tong)直徑(jing)與坯(pi)料直徑(jing),擠(ji)(ji)(ji)(ji)壓(ya)(ya)墊(dian)(dian)(dian)(dian)直徑(jing)之(zhi)間的(de)關系(xi)見表7-9.

3. 擠壓墊(dian)的使用(yong)壽命

在(zai)現代臥式管型材擠壓(ya)(ya)機上,采用熱模鋼(gang)(如3Cr2W8V或4CrW2Si)制作(zuo)的擠壓(ya)(ya)墊的使用壽命:

當擠(ji)壓碳素鋼(gang)管(guan)時(shi)約為500~600次/只,擠(ji)壓不(bu)銹鋼(gang)管(guan)時(shi)為150~200次/只。

a. 擠壓墊制造時的機加工公差

擠壓墊制造(zao)時(shi)(shi)的機加工公差(cha):外(wai)徑公差(cha)為(wei)(wei)(wei)±0.3mm;當d=40~100mm時(shi)(shi)內(nei)徑公差(cha)為(wei)(wei)(wei)+0.2mm,當d>101mm時(shi)(shi)內(nei)徑公差(cha)為(wei)(wei)(wei)+0.3mm;厚(hou)度公差(cha)為(wei)(wei)(wei)±0.1mm.

b. 擠(ji)壓(ya)墊的損(sun)壞形式

擠壓墊的(de)使用壽命與擠壓墊的(de)材料、擠壓坯(pi)料的(de)性能和(he)擠壓工藝參(can)數有關,一般為(wei)50~300次/只(zhi)。

擠(ji)(ji)壓(ya)(ya)過(guo)程中,擠(ji)(ji)壓(ya)(ya)墊(dian)(dian)(dian)(dian)一直處在高溫高壓(ya)(ya)的(de)(de)(de)條件下(xia)工作(zuo)。擠(ji)(ji)壓(ya)(ya)墊(dian)(dian)(dian)(dian)的(de)(de)(de)前錐形(xing)(xing)(xing)端面長時間地與高溫坯(pi)料接(jie)觸,導致其(qi)機械強(qiang)度喪失。同時受到坯(pi)料端面變(bian)形(xing)(xing)(xing)金(jin)屬(shu)向中心(xin)流動時的(de)(de)(de)強(qiang)烈沖刷,引(yin)起(qi)擠(ji)(ji)壓(ya)(ya)墊(dian)(dian)(dian)(dian)棱(leng)緣的(de)(de)(de)變(bian)形(xing)(xing)(xing)和黏結。當擠(ji)(ji)壓(ya)(ya)將近(jin)結束時,擠(ji)(ji)壓(ya)(ya)墊(dian)(dian)(dian)(dian)的(de)(de)(de)變(bian)形(xing)(xing)(xing)區移動至陷(xian)入變(bian)形(xing)(xing)(xing)錐的(de)(de)(de)“死(si)區”內,進一步加劇(ju)了邊緣的(de)(de)(de)損壞。同時,擠(ji)(ji)壓(ya)(ya)墊(dian)(dian)(dian)(dian)的(de)(de)(de)邊緣金(jin)屬(shu)逐漸(jian)向變(bian)形(xing)(xing)(xing)區的(de)(de)(de)塑性金(jin)屬(shu)的(de)(de)(de)旁邊彎曲。當擠(ji)(ji)壓(ya)(ya)墊(dian)(dian)(dian)(dian)熱處理后的(de)(de)(de)硬度過(guo)高或遭受不均勻的(de)(de)(de)急冷時,會引(yin)起(qi)擠(ji)(ji)壓(ya)(ya)墊(dian)(dian)(dian)(dian)的(de)(de)(de)開裂。

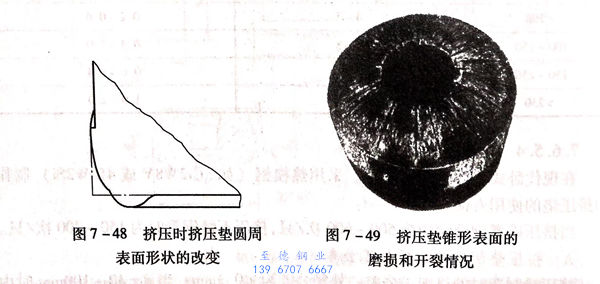

圖(tu)7-47所示為(wei)臥(wo)式鋼管型材擠壓(ya)(ya)(ya)(ya)機(ji)的(de)(de)擠壓(ya)(ya)(ya)(ya)墊。圖(tu)7-48所示為(wei)擠壓(ya)(ya)(ya)(ya)時擠壓(ya)(ya)(ya)(ya)墊形(xing)狀的(de)(de)改(gai)變狀況。擠壓(ya)(ya)(ya)(ya)墊工作溫度最高(gao)的(de)(de)錐(zhui)形(xing)頂部是裂紋(wen)的(de)(de)起(qi)源(yuan),經多(duo)次使(shi)用(yong)后,裂紋(wen)發展形(xing)成深(shen)溝。而(er)擠壓(ya)(ya)(ya)(ya)金屬的(de)(de)摩(mo)擦磨(mo)損,則(ze)以(yi)徑向劃(hua)道和(he)粗糙性形(xing)式留(liu)下(xia)痕跡。此(ci)外,在(zai)軸向擠壓(ya)(ya)(ya)(ya)力的(de)(de)作用(yong)下(xia),擠壓(ya)(ya)(ya)(ya)墊被壓(ya)(ya)(ya)(ya)縮,尺(chi)寸減小。

圖7-49所示為(wei)擠壓(ya)(ya)(ya)墊(dian)(dian)錐(zhui)形(xing)表面的磨(mo)損(sun)(sun)和(he)開裂情況(kuang)。從圖7-49可以看出,擠壓(ya)(ya)(ya)墊(dian)(dian)工作(zuo)最高的錐(zhui)形(xing)頂部是裂紋的起(qi)源,擠壓(ya)(ya)(ya)墊(dian)(dian)經多次使用(yong)后裂紋發展(zhan)形(xing)成深溝,而擠壓(ya)(ya)(ya)金屬的摩(mo)擦和(he)磨(mo)損(sun)(sun)則以劃道(dao)和(he)粗紋形(xing)式留下痕跡。此外,在軸向擠壓(ya)(ya)(ya)力(li)的作(zuo)用(yong)下,擠壓(ya)(ya)(ya)墊(dian)(dian)被(bei)壓(ya)(ya)(ya)縮(suo)和(he)尺寸變小。

擠壓(ya)墊(dian)(dian)的(de)邊(bian)緣倒成圓角,有利于提高擠壓(ya)墊(dian)(dian)的(de)使(shi)用壽命。5~6個(ge)(或更多個(ge))擠壓(ya)墊(dian)(dian)輪(lun)流使(shi)用,使(shi)其在每次(ci)工作(zuo)后能(neng)得(de)到充分的(de)冷卻,也有利于擠壓(ya)墊(dian)(dian)壽命的(de)提高。

對于非開(kai)裂性損(sun)壞的擠壓墊可以采用焊條(tiao)焊接的方法進行(xing)修補。