不銹鋼的爐中釬焊(han)一般是在某種保護性氣(qi)(qi)氛(fen)下或(huo)真空(kong)中進行,保護氣(qi)(qi)氛(fen)有(you)氫氣(qi)(qi)、分解氨和氬氣(qi)(qi)。

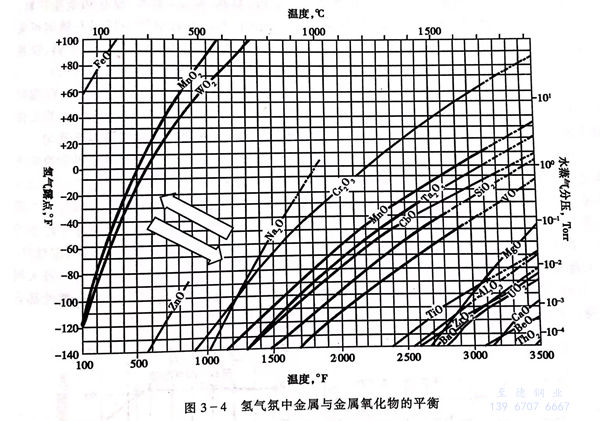

干燥的氫氣或分解氨常用做爐中釬焊不銹鋼時的還原性保護氣氛,它們可還原不銹(xiu)鋼表面的氧化膜,并保護不銹鋼表面在釬焊時不再氧化。一般要求氫氣或分解氨的露點低于-40℃,但也要考慮保護氣體的露點要與釬焊溫度及母材的成分相適應。釬焊溫度越低、不銹鋼表面氧化膜越穩定,要求氫氣露點越低,見圖3-4。使用分解氨作保護氣氛時,必須保證NH3完全分解,避免殘余的NH3使不銹鋼表面氮化。

使(shi)(shi)用(yong)氫(qing)氣或分解(jie)氨作保護氣氛的(de)(de)好(hao)處是:可實現釬焊爐(lu)的(de)(de)連續工(gong)作,便(bian)于(yu)大批量生(sheng)產(chan);釬焊過程中不(bu)需(xu)使(shi)(shi)用(yong)釬劑,且(qie)焊后(hou)工(gong)件(jian)(jian)(jian)光(guang)亮,無需(xu)任何焊后(hou)工(gong)件(jian)(jian)(jian)表面(mian)清理(li)工(gong)作;可配合選用(yong)的(de)(de)釬料品種(zhong)多(duo);在批量生(sheng)產(chan)條件(jian)(jian)(jian)下焊接成本(ben)低。但是使(shi)(shi)用(yong)氫(qing)氣或分解(jie)氨作保護氣氛時要注意生(sheng)產(chan)安全(quan),當空氣中混有4%~74%的(de)(de)氫(qing)氣或12.5%~27%氨氣時,會(hui)因燃(ran)燒而產(chan)生(sheng)爆(bao)炸。

作(zuo)為惰(duo)性(xing)氣(qi)體,氬氣(qi)可用(yong)(yong)作(zuo)爐中(zhong)釬(han)焊不銹(xiu)鋼(gang)時(shi)的(de)保護氣(qi)氛。與氫氣(qi)和分解氨不同(tong),氬氣(qi)不具有(you)還原性(xing),只是(shi)利用(yong)(yong)其(qi)惰(duo)性(xing)保護不銹(xiu)鋼(gang)表面(mian)在釬(han)焊過程中(zhong)不氧化,所以不銹(xiu)鋼(gang)進爐釬(han)焊前必(bi)須(xu)徹底清除其(qi)表面(mian)的(de)氧化膜(mo),并且一般要求氬氣(qi)的(de)露點低于-40℃。

使用氬(ya)氣(qi)作保護(hu)氣(qi)氛一般是因為以下某種或多(duo)種原因:①. 可采(cai)用含高(gao)蒸(zheng)汽壓元素的(de)釬(han),如錳基(ji)釬(han)料或含錳較多(duo)的(de)釬(han)料;②. 單(dan)件或小批量釬(han)焊時,設備成本低;③. 不銹鋼與(yu)異種材釬(han)焊時避免某些材料與(yu)爐內氣(qi)氛的(de)反(fan)應(ying),如在(zai)含氫(qing)氣(qi)氛中(zhong)釬(han)焊連接(jie)不銹鋼與(yu)鈦合金時,鈦金吸氫(qing)并與(yu)氫(qing)反(fan)應(ying);④. 生產(chan)過程安全。

使用氬氣作保護氣氛時,常見的做法是將真空爐抽至高真空后(10-2~10-3Pa)充入少量氬氣,關閉爐體氣閥后升溫。或者在特制的密封容器內通人流動的氬氣,將空氣趕凈后,容器放入馬弗爐內加熱。也可在趕凈空氣后,關閉氣路,容器放人馬弗爐內加熱,但在升溫過

程中要隨(sui)時注意容(rong)(rong)器(qi)內(nei)的(de)壓(ya)力,當容(rong)(rong)器(qi)內(nei)壓(ya)力超(chao)過大氣(qi)壓(ya)較多時應(ying)隨(sui)時放出一(yi)些氣(qi)體,以保證容(rong)(rong)器(qi)完(wan)好和(he)生(sheng)產安(an)全(quan)。使(shi)用特制的(de)容(rong)(rong)器(qi)還(huan)有(you)另一(yi)個(ge)便利:當使(shi)用未經凈化的(de)普通瓶裝氬氣(qi)時,可向釬(han)焊爐內(nei)通入少(shao)(shao)許(xu)BF3氣(qi)體釬(han)劑,或加入少(shao)(shao)許(xu)氟(fu)硼酸鉀(jia),氟(fu)硼酸鉀(jia)在800~900℃分解(jie)產生(sheng)BF3.BF3可以去除金屬表(biao)面的(de)氧化物(wu)(wu),促(cu)進釬(han)料(liao)的(de)潤濕。氣(qi)體釬(han)劑的(de)使(shi)用濃度一(yi)般控制在0.1%~0.001%(體積分數),避免焊后形成殘渣(zha)。氟(fu)化物(wu)(wu)對人體有(you)害,要注意工(gong)作(zuo)場(chang)地的(de)通風。

在真空爐中釬焊不銹鋼是一種常用且理想的方法。釬焊不銹鋼時一般要求真空度達到10-2~10-3Pa,并且要求真空爐的氣體泄漏率小于10-2Pa/s.使用真空爐釬焊不銹鋼的好處是:可避免不銹鋼的氧化;可避免釬焊爐內氣氛對母材的不良影響;真空爐升、降溫速度慢,工件不變形或變形量很小;無論以何種方式添加釬料均不會在接頭內形成氣孔;無需消耗保護氣體;無需氣體凈化裝置;無安全隱患;帶有充氣及快冷風扇置的真空爐同樣具有較高的生產率,并可實現釬焊與焊后工件熱處理的結合。

在氫氣或分解氨氣氛爐中釬焊不銹鋼可使用紫銅、銅基、銀基、錳基、鎳基和金基釬料。在氬氣氛爐中釬焊不銹鋼可使用銅基、銀基、錳基、金基釬料。在真空爐中釬焊不銹鋼可采用紫銅、不含易蒸發元素(Zn、Cd)或僅含少量高蒸汽壓元素(Mn)的銅基和銀基釬料、鎳基釬料和金基釬料。使用鎳基釬料釬焊不銹鋼薄件時,要選擇對母材溶蝕傾向小的釬料。

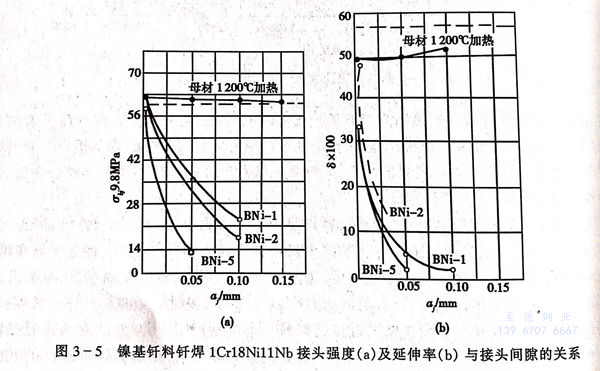

爐中(zhong)(zhong)釬(han)(han)(han)焊(han)(han)時(shi)(shi)(shi)影(ying)響釬(han)(han)(han)焊(han)(han)接(jie)(jie)頭(tou)(tou)性能(neng),特(te)別是力學性能(neng)的(de)(de)主要工藝參數(shu)(shu)包(bao)釬(han)(han)(han)焊(han)(han)溫(wen)(wen)(wen)度(du)(du)、保(bao)溫(wen)(wen)(wen)時(shi)(shi)(shi)間(jian)(jian)(jian)(jian)。釬(han)(han)(han)焊(han)(han)溫(wen)(wen)(wen)度(du)(du)一般選(xuan)擇在(zai)(zai)(zai)釬(han)(han)(han)料(liao)液相線溫(wen)(wen)(wen)度(du)(du)以上50~100℃,保(bao)溫(wen)(wen)(wen)時(shi)(shi)(shi)間(jian)(jian)(jian)(jian)在(zai)(zai)(zai)5~10min.當(dang)工件(jian)較大時(shi)(shi)(shi),可在(zai)(zai)(zai)升溫(wen)(wen)(wen)過(guo)程中(zhong)(zhong)釬(han)(han)(han)料(liao)固(gu)相線溫(wen)(wen)(wen)度(du)(du)以下(xia)(xia)(xia)某溫(wen)(wen)(wen)度(du)(du)保(bao)溫(wen)(wen)(wen)一段時(shi)(shi)(shi)間(jian)(jian)(jian)(jian),確(que)保(bao)工件(jian)溫(wen)(wen)(wen)度(du)(du)均勻。使用鎳(nie)(nie)基釬(han)(han)(han)料(liao)時(shi)(shi)(shi),除了釬(han)(han)(han)焊(han)(han)溫(wen)(wen)(wen)度(du)(du)和(he)(he)保(bao)溫(wen)(wen)(wen)時(shi)(shi)(shi)間(jian)(jian)(jian)(jian)外,釬(han)(han)(han)縫間(jian)(jian)(jian)(jian)隙(xi)也是接(jie)(jie)頭(tou)(tou)強(qiang)度(du)(du)和(he)(he)塑性的(de)(de)決(jue)定因素之一。圖3-5、圖3-6顯示了三種鎳(nie)(nie)基釬(han)(han)(han)料(liao)釬(han)(han)(han)焊(han)(han)不(bu)銹鋼時(shi)(shi)(shi)釬(han)(han)(han)焊(han)(han)接(jie)(jie)頭(tou)(tou)強(qiang)度(du)(du)與釬(han)(han)(han)縫間(jian)(jian)(jian)(jian)隙(xi)的(de)(de)關系。為降低釬(han)(han)(han)料(liao)的(de)(de)熔點,鎳(nie)(nie)基釬(han)(han)(han)料(liao)中(zhong)(zhong)含有較多(duo)的(de)(de)硼、硅、磷(lin),它們在(zai)(zai)(zai)釬(han)(han)(han)料(liao)組織中(zhong)(zhong)以脆性的(de)(de)硼化物、硅化物、磷(lin)化物形(xing)式(shi)存(cun)在(zai)(zai)(zai)。釬(han)(han)(han)焊(han)(han)時(shi)(shi)(shi)在(zai)(zai)(zai)一定的(de)(de)釬(han)(han)(han)焊(han)(han)溫(wen)(wen)(wen)度(du)(du)和(he)(he)保(bao)溫(wen)(wen)(wen)時(shi)(shi)(shi)間(jian)(jian)(jian)(jian)下(xia)(xia)(xia),當(dang)釬(han)(han)(han)縫間(jian)(jian)(jian)(jian)隙(xi)小于某一數(shu)(shu)值(zhi),硼、硅、磷(lin)向(xiang)母(mu)材擴散(san)充分(fen),凝(ning)固(gu)后釬(han)(han)(han)縫組織為鎳(nie)(nie)基固(gu)溶體,釬(han)(han)(han)縫強(qiang)度(du)(du)高(gao)、塑性好,此數(shu)(shu)值(zhi)稱作該(gai)釬(han)(han)(han)料(liao)在(zai)(zai)(zai)此釬(han)(han)(han)焊(han)(han)溫(wen)(wen)(wen)度(du)(du)和(he)(he)保(bao)溫(wen)(wen)(wen)時(shi)(shi)(shi)間(jian)(jian)(jian)(jian)下(xia)(xia)(xia)的(de)(de)最大釬(han)(han)(han)焊(han)(han)間(jian)(jian)(jian)(jian)隙(xi)。當(dang)釬(han)(han)(han)縫間(jian)(jian)(jian)(jian)隙(xi)超(chao)過(guo)最大間(jian)(jian)(jian)(jian)隙(xi),釬(han)(han)(han)縫中(zhong)(zhong)硼、硅、磷(lin)向(xiang)母(mu)材擴散(san)不(bu)充分(fen),釬(han)(han)(han)縫中(zhong)(zhong)會存(cun)在(zai)(zai)(zai)脆性化合(he)物,釬(han)(han)(han)縫的(de)(de)強(qiang)度(du)(du)和(he)(he)塑性都會下(xia)(xia)(xia)降。而且在(zai)(zai)(zai)一定范圍內(nei),釬(han)(han)(han)縫越寬,釬(han)(han)(han)縫中(zhong)(zhong)脆性相越多(duo),接(jie)(jie)頭(tou)(tou)的(de)(de)強(qiang)度(du)(du)和(he)(he)塑性越低。

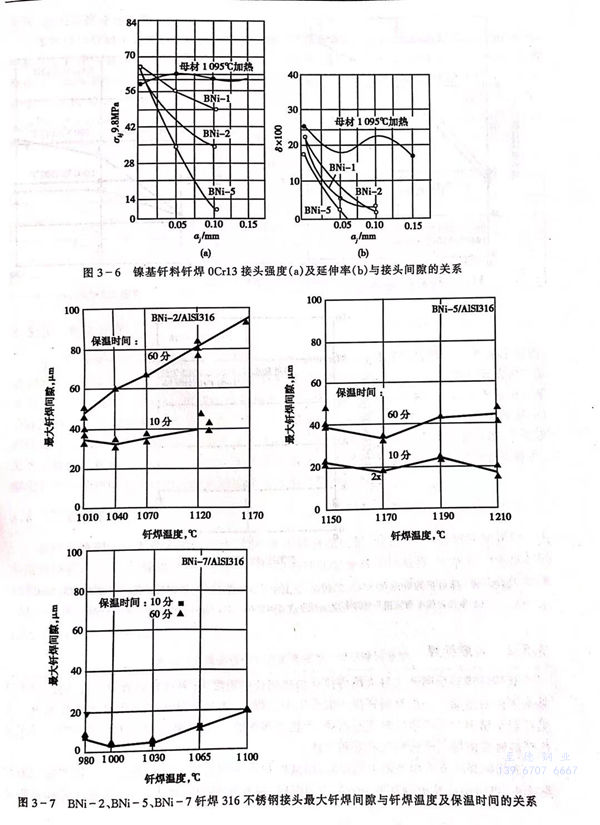

在釬焊實際(ji)部件(jian)時(shi),有(you)時(shi)部件(jian)加工精(jing)度或(huo)裝配(pei)精(jing)度很(hen)難保證釬縫間隙(xi)(xi)很(hen)小,適當(dang)地(di)提高釬焊溫度或(huo)延(yan)長保溫時(shi)間可增大(da)(da)(da)最(zui)大(da)(da)(da)釬焊間隙(xi)(xi),見(jian)圖(tu)3-7。當(dang)在高溫下長時(shi)間保溫造成母材晶(jing)粒過分長大(da)(da)(da)或(huo)釬料(liao)對(dui)母材溶蝕過度時(shi),也可在焊后接(jie)頭(tou)冷(leng)卻到某一較低溫度保溫,通(tong)過擴散(san)(san)消除釬縫中(zhong)的脆(cui)性相(xiang)而增大(da)(da)(da)最(zui)大(da)(da)(da)釬焊間隙(xi)(xi),見(jian)圖(tu)3-8。但(dan)由于磷(lin)原子較大(da)(da)(da),向母材中(zhong)擴散(san)(san)困難,這些措(cuo)施對(dui)Ni-Cr-P和Ni-P這類釬料(liao)作用不大(da)(da)(da)。

爐中釬焊時為控制釬料不流到接頭外其他部位或造成工件與卡具的粘連,可在防止釬料潤濕處涂止焊劑。釬焊不銹鋼時可以用TiO2、Y2O3或云母粉與乙醇混和后做止焊劑。