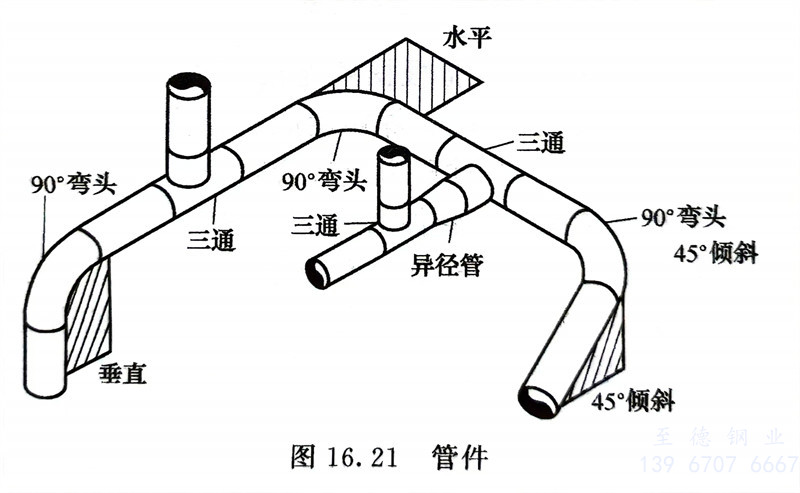

管件在管系中起著改變走向、改變標高或改變直徑、封閉管端以及由主管上引出支管的作用。在石油化工裝置中管道品種多,管系復雜,形狀各異,簡繁不等,所用的管件品種、材質、數量也就很多,選用時需要考慮的因素也多,如圖16.21所示。一般按用途、連接方式、材料、加工方式分類。

一、按用(yong)途分(fen)類

①. 直管與直管連接(jie): 有活接(jie)頭、管箍。

②. 改變走向:有彎頭、彎管。

③. 分支:有三通、四通、承插焊管接頭、螺紋管接頭、加強管接頭,管箍、管嘴。

④. 改變管徑:有異徑管(大小頭)、異徑短節、異徑管箍、內外絲。

⑤. 封閉管端:有管帽、絲堵。

⑥. 其他:有螺紋短節、翻邊管接頭等。

二、按連(lian)接方式分類

根據(ju)管(guan)(guan)(guan)(guan)(guan)件(jian)(jian)(jian)端部連(lian)接(jie)(jie)(jie)形式可(ke)將管(guan)(guan)(guan)(guan)(guan)件(jian)(jian)(jian)分為對(dui)焊連(lian)接(jie)(jie)(jie)管(guan)(guan)(guan)(guan)(guan)件(jian)(jian)(jian)(簡(jian)稱對(dui)焊管(guan)(guan)(guan)(guan)(guan)件(jian)(jian)(jian))、承(cheng)插焊連(lian)接(jie)(jie)(jie)管(guan)(guan)(guan)(guan)(guan)件(jian)(jian)(jian)(簡(jian)稱承(cheng)插焊管(guan)(guan)(guan)(guan)(guan)件(jian)(jian)(jian))、螺紋(wen)連(lian)接(jie)(jie)(jie)管(guan)(guan)(guan)(guan)(guan)件(jian)(jian)(jian)(簡(jian)稱螺紋(wen)管(guan)(guan)(guan)(guan)(guan)件(jian)(jian)(jian))、法蘭連(lian)接(jie)(jie)(jie)管(guan)(guan)(guan)(guan)(guan)件(jian)(jian)(jian)以及其他管(guan)(guan)(guan)(guan)(guan)件(jian)(jian)(jian)。在石油化(hua)工裝置(zhi)的(de)配管(guan)(guan)(guan)(guan)(guan)設(she)計中(zhong),常(chang)用的(de)對(dui)焊管(guan)(guan)(guan)(guan)(guan)件(jian)(jian)(jian)、支管(guan)(guan)(guan)(guan)(guan)臺(tai)、承(cheng)插焊與螺紋(wen)連(lian)接(jie)(jie)(jie)管(guan)(guan)(guan)(guan)(guan)件(jian)(jian)(jian)的(de)形式。法蘭管(guan)(guan)(guan)(guan)(guan)件(jian)(jian)(jian)多(duo)用于特殊配管(guan)(guan)(guan)(guan)(guan)場合,使用范(fan)圍與數量相(xiang)對(dui)比較少。需要(yao)時可(ke)根據(ju)GB/T 17185《鋼(gang)制法蘭管(guan)(guan)(guan)(guan)(guan)件(jian)(jian)(jian)》的(de)規定選用。

三、按材料分類(lei)

有碳素鋼管件、合金鋼管件、不銹鋼(gang)管件(jian)、塑料管件、橡膠管件、鑄鐵管件、鍛鋼管件等。

四、按加(jia)工方式(shi)分

有(you)無縫、焊接、鍛制、鑄造。