不銹鋼法蘭墊(dian)片(pian)的主要(yao)參(can)數包括墊(dian)片(pian)的有(you)效密封寬度、墊(dian)片(pian)的性能(neng)參(can)數、墊(dian)片(pian)公(gong)稱(cheng)通(tong)徑或公(gong)稱(cheng)尺寸及墊(dian)片(pian)公(gong)稱(cheng)壓力。

一、不(bu)銹(xiu)鋼法蘭(lan)墊片的有效密封寬度(du)

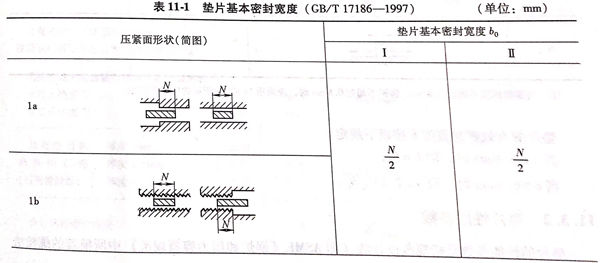

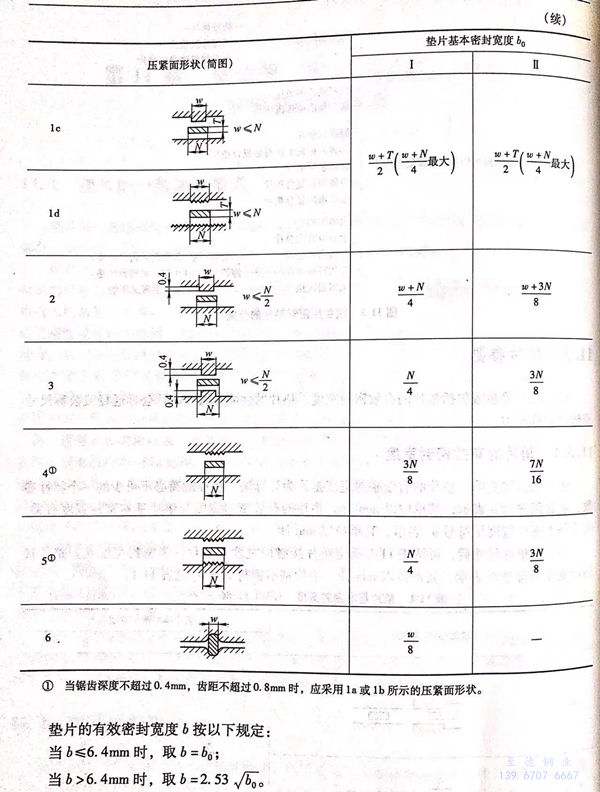

法蘭密封接頭中,墊片的有效密封寬度是作為計算法蘭螺栓載荷必不可少的一個特性參數,通常用符號b表示,其單位以mm計。不銹鋼法(fa)蘭墊片的有效密封寬度與墊片基本密封寬度有關。墊片基本密封寬度用符號b0表示,其單位以mm計。

當選定墊片尺寸后,可按表11-1確定墊片接觸面寬度和墊片基本密封寬度b0。墊片接觸面寬度以符號N表示,其單位以mm計。墊片基本密封寬度b0見表11-1。

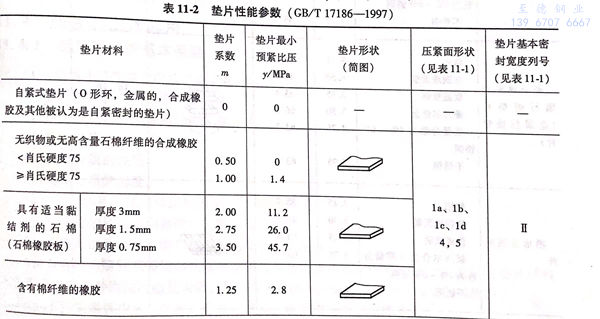

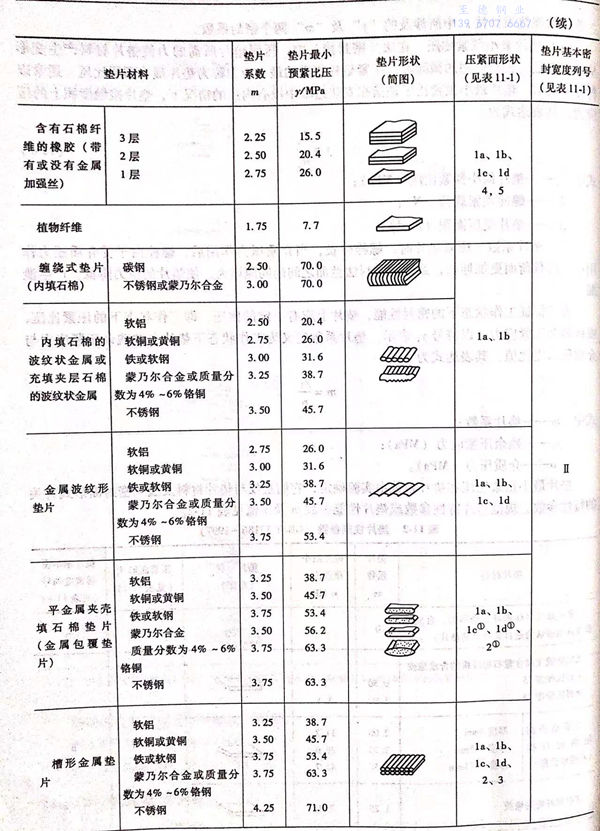

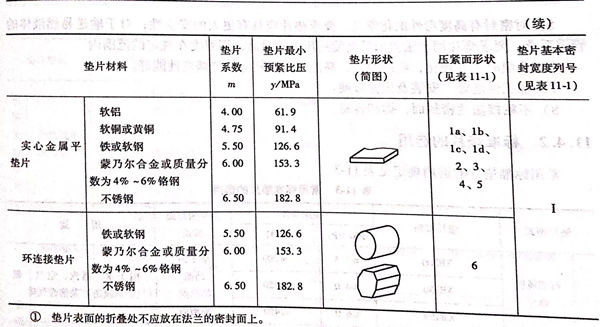

二、不(bu)銹鋼法(fa)蘭墊片性(xing)能參(can)數

不銹鋼法(fa)蘭(lan)墊片的(de)性能參(can)數(shu)是指規(gui)范(fan)設計(ji)法(fa)(即ASME《鍋爐和壓(ya)力容器規(gui)范(fan)》中(zhong)所推(tui)薦的(de)螺(luo)栓(shuan)法(fa)蘭(lan)連(lian)接的(de)規(gui)范(fan)設計(ji)法(fa))中(zhong)所涉及(ji)的(de)“y”及(ji)“m”兩個密封(feng)系數(shu)。

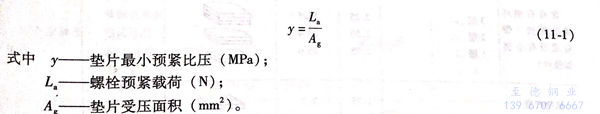

1. 不銹鋼法蘭墊片最小預緊比壓

在(zai)法蘭(lan)密封接頭(tou)中,壓(ya)(ya)(ya)緊(jin)墊(dian)(dian)片(pian)(pian)所需的(de)力使墊(dian)(dian)片(pian)(pian)材料產生變形從而填滿(man)法蘭(lan)密封面(mian)間的(de)微間隙。壓(ya)(ya)(ya)緊(jin)墊(dian)(dian)片(pian)(pian)所需的(de)最小應力稱(cheng)為(wei)墊(dian)(dian)片(pian)(pian)最小預緊(jin)比壓(ya)(ya)(ya),通常以符號y表示(shi)。墊(dian)(dian)片(pian)(pian)最小預緊(jin)比壓(ya)(ya)(ya)是指在(zai)安裝過程(cheng)中沒有內(nei)壓(ya)(ya)(ya)的(de)情(qing)況下,墊(dian)(dian)片(pian)(pian)接觸面(mian)積上的(de)壓(ya)(ya)(ya)應力,其表達式為(wei):

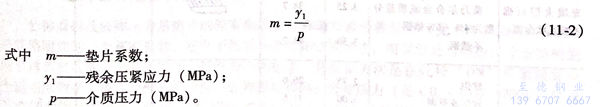

2. 不(bu)銹鋼(gang)法蘭(lan)墊(dian)片系數(shu)

壓緊墊片時,螺栓伸長,當介(jie)質壓力(li)(li)作用(yong)后,螺栓由于受介(jie)質壓力(li)(li)作用(yong)產生的(de)載荷而更加伸長,致使兩密封(feng)法蘭面之間(jian)的(de)間(jian)隙增大(da),使墊片的(de)應力(li)(li)降低,產生泄漏。

為(wei)了保證工作狀態(tai)下(xia)的密封性能,墊片上(shang)應(ying)(ying)有一定(ding)(ding)的比(bi)壓(ya),即工作狀態(tai)下(xia)的壓(ya)緊比(bi)壓(ya),或稱殘(can)余壓(ya)緊應(ying)(ying)力(li),以符號(hao)y1表示。墊片系數定(ding)(ding)義為(wei)工作狀態(tai)下(xia)墊片上(shang)的殘(can)余壓(ya)緊應(ying)(ying)力(li)與介質(zhi)壓(ya)力(li)之(zhi)比(bi)值,其表達式(shi)為(wei):

不銹鋼法(fa)蘭墊(dian)片(pian)(pian)最小(xiao)預緊比壓(ya)和墊(dian)片(pian)(pian)系數(shu)(shu)(shu)由實驗(yan)確(que)定,它們是(shi)僅與(yu)墊(dian)片(pian)(pian)材料及法(fa)蘭密封(feng)面形式有(you)關(guan)的特性參數(shu)(shu)(shu)。規范(fan)墊(dian)片(pian)(pian)特性參數(shu)(shu)(shu)或墊(dian)片(pian)(pian)性能參數(shu)(shu)(shu)m及y值見表11-2。

三、不銹鋼(gang)法蘭墊片公稱通徑及(ji)公稱壓力

公(gong)(gong)稱(cheng)通(tong)(tong)徑(jing)(jing)及公(gong)(gong)稱(cheng)壓(ya)力(li)是(shi)(shi)墊(dian)片(pian)(pian)(pian)的(de)配套參數。公(gong)(gong)稱(cheng)通(tong)(tong)徑(jing)(jing)或(huo)公(gong)(gong)稱(cheng)尺(chi)(chi)寸(cun)(見(jian)GB/T 1047-2005)是(shi)(shi)管路附(fu)件的(de)一(yi)個(ge)基(ji)本參數,它并不是(shi)(shi)某一(yi)個(ge)實際結構尺(chi)(chi)寸(cun),而僅僅是(shi)(shi)與(yu)制造尺(chi)(chi)寸(cun)密切相(xiang)關的(de)經(jing)過(guo)圓整后(hou)的(de)一(yi)個(ge)名(ming)義尺(chi)(chi)寸(cun),僅作為(wei)一(yi)種標(biao)(biao)志,其(qi)標(biao)(biao)記(ji)方法(fa)(fa)(fa)是(shi)(shi)在(zai)代號“DN”后(hou)緊跟著一(yi)個(ge)適當的(de)數字(zi)。墊(dian)片(pian)(pian)(pian)公(gong)(gong)稱(cheng)通(tong)(tong)徑(jing)(jing)與(yu)法(fa)(fa)(fa)蘭(lan)公(gong)(gong)稱(cheng)通(tong)(tong)徑(jing)(jing)相(xiang)同;公(gong)(gong)稱(cheng)壓(ya)力(li)(見(jian)GB/T 1048-2005)是(shi)(shi)指與(yu)管路附(fu)件(如(ru)法(fa)(fa)(fa)蘭(lan)、管件、閥(fa)門等(deng))機械強度有關的(de)設計給定(ding)壓(ya)力(li),是(shi)(shi)一(yi)個(ge)經(jing)過(guo)圓整后(hou)的(de)名(ming)義值(zhi),也是(shi)(shi)僅作為(wei)一(yi)種標(biao)(biao)志,其(qi)標(biao)(biao)記(ji)方法(fa)(fa)(fa)是(shi)(shi)在(zai)代號“PN”后(hou)緊跟一(yi)個(ge)適當的(de)數字(zi)。墊(dian)片(pian)(pian)(pian)公(gong)(gong)稱(cheng)壓(ya)力(li)亦與(yu)法(fa)(fa)(fa)蘭(lan)公(gong)(gong)稱(cheng)壓(ya)力(li)相(xiang)同。