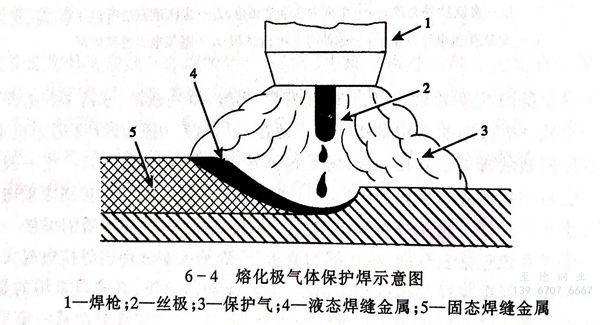

熔(rong)(rong)化(hua)極氣體保(bao)護焊是用可熔(rong)(rong)化(hua)的焊絲與(yu)被焊工(gong)件之間的電弧(hu)作為(wei)熱(re)源來熔(rong)(rong)化(hua)焊絲與(yu)母材(cai)金(jin)屬,并(bing)向(xiang)焊接區輸送(song)保(bao)護氣體,保(bao)護電弧(hu)和熔(rong)(rong)化(hua)金(jin)屬,見(jian)圖6-4。

熔化極氣體保護焊用焊絲作為電極,克服了鎢極對電流的限制,焊接電流可以提高,大大提高熔敷速度從而提高效率。熔化極氣體保護焊的焊絲有實芯焊絲和藥芯焊絲,按保護氣體分有惰性氣體保護焊(一般為氬氣)、氧化性氣體保護焊(CO2)以及混合氣體保護焊。熔化極氣體保護焊焊接不銹鋼的熔滴過渡形式有噴射過渡、短路過渡和滴狀過渡三種。

滴(di)狀過渡(du)(du)時(shi),熔滴(di)直(zhi)徑比較(jiao)(jiao)大,導致了(le)飛濺較(jiao)(jiao)大,焊接(jie)過程不(bu)穩(wen)定(ding),生產中幾乎不(bu)用(yong)(yong);短路過渡(du)(du)電(dian)弧(hu)間隙小(xiao),電(dian)弧(hu)電(dian)壓較(jiao)(jiao)低,電(dian)流(liu)比較(jiao)(jiao)小(xiao),適于(yu)薄板焊接(jie);噴(pen)(pen)射過渡(du)(du)是(shi)最常用(yong)(yong)的,對于(yu)一定(ding)直(zhi)徑的焊絲和(he)保護氣體,當(dang)焊接(jie)電(dian)流(liu)增(zeng)大到一定(ding)值電(dian)流(liu)(臨界電(dian)流(liu))時(shi),焊絲熔化的金屬被壓縮成尖(jian)狀,以細(xi)小(xiao)熔滴(di)高(gao)速軸向射入熔池,即噴(pen)(pen)射過渡(du)(du)。