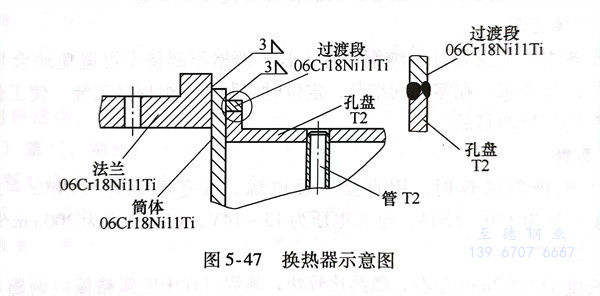

換熱器是冷凝器中主要部件,其中孔盤與筒體的連接是純銅T2與不銹鋼 06Cr18Ni11Ti 的焊接。

1. 焊接性分析

為(wei)了減少孔(kong)(kong)盤(pan)(pan)與筒體(ti)(ti)焊(han)接(jie)時(shi)產生較大的(de)(de)焊(han)接(jie)拘(ju)束力,避免(mian)焊(han)接(jie)接(jie)頭(tou)有形成(cheng)裂(lie)紋的(de)(de)可能,改變了孔(kong)(kong)盤(pan)(pan)原(yuan)有結構。將孔(kong)(kong)盤(pan)(pan)改為(wei)焊(han)接(jie)件,在(zai)孔(kong)(kong)盤(pan)(pan)上增加過渡段06Cr18Ni11Ti與孔(kong)(kong)盤(pan)(pan)進行(xing)對接(jie)焊(han),如圖5-47所示。然后(hou)過渡段與筒體(ti)(ti)均(jun)為(wei)同一材(cai)質(zhi)的(de)(de)06Cr18Ni11Ti,便于施焊(han)。

2. 工(gong)藝過程

a. 將過(guo)(guo)渡(du)段分(fen)成3~6等(deng)份與孔盤(pan)組成環焊縫(feng),然后再焊過(guo)(guo)渡(du)段的(de)縱焊縫(feng),以此減少焊接拘束力(li)。

b. 孔盤(pan)與過(guo)渡段施(shi)焊(han)以前要對孔盤(pan)進行預熱(re),預熱(re)溫度為(wei)(wei)400~500℃。采用焊(han)條電(dian)(dian)弧焊(han)施(shi)焊(han),選用T227焊(han)條,直徑(jing)為(wei)(wei)3.2mm。焊(han)接電(dian)(dian)流140~160A,電(dian)(dian)弧電(dian)(dian)壓(ya)為(wei)(wei)25~30V。施(shi)焊(han)時,電(dian)(dian)弧應偏向純(chun)銅(tong)側(ce),才能得到滿意的焊(han)接接頭(tou)。

c. 焊(han)(han)接分成3~6等分過(guo)渡段的縱焊(han)(han)縫,仍采用(yong)焊(han)(han)條(tiao)電弧焊(han)(han),選用(yong)A102焊(han)(han)條(tiao),直徑(jing)為3.2mm,焊(han)(han)接電流(liu)為90~110A,電弧電壓為25~30V。

d. 最后組裝法蘭、筒體與帶有過渡段的孔(kong)盤進(jin)行(xing)焊條電(dian)弧焊,獲得成功,未發現裂(lie)紋。