馬氏體低(di)溫(wen)用(yong)鋼主(zhu)要是(shi)指(zhi)制造(zao)、運輸及(ji)(ji)儲存液化氣(qi)(qi)體的機(ji)械(xie)設備、超導設備、核聚(ju)變反應設備等(deng)所(suo)用(yong)的超高強度(du)(du)、超低(di)溫(wen)材料。這里只(zhi)涉及(ji)(ji)常(chang)(chang)壓下液化溫(wen)度(du)(du)在(zai)-103℃以下的常(chang)(chang)用(yong)氣(qi)(qi)體(乙(yi)烯:-103℃;天(tian)然(ran)氣(qi)(qi):-165℃;氧:-183℃;空(kong)氣(qi)(qi):-190℃;氮:-196℃;氫:-253℃;氯:-269℃)及(ji)(ji)一些(xie)液化溫(wen)度(du)(du)在(zai)-180--80℃之間(jian)的碳氫化合(he)(he)物(如甲烷、乙(yi)烷)等(deng)所(suo)用(yong)的高合(he)(he)金細晶粒鐵素體鋼。

作為低(di)溫用鋼(gang),應具有如(ru)下(xia)性(xing)(xing)(xing)能(neng):低(di)溫下(xia)組織穩定(ding),不產生相變,以保持力學(xue)性(xing)(xing)(xing)能(neng)及(ji)物理(li)性(xing)(xing)(xing)較(jiao)為穩定(ding);有良好的(de)(de)低(di)溫韌性(xing)(xing)(xing):良好的(de)(de)焊接性(xing)(xing)(xing)和加(jia)工性(xing)(xing)(xing)能(neng);有時還有其他特殊要求,如(ru)無(wu)磁性(xing)(xing)(xing)等。

9%Ni鋼是低(di)碳馬氏(shi)體型低(di)溫用(yong)(yong)鋼,作為液化天然氣(LNG)及液氨用(yong)(yong)鋼,已被世界各國(guo)普遍采用(yong)(yong),其使用(yong)(yong)溫度可(ke)達(da)-196℃。

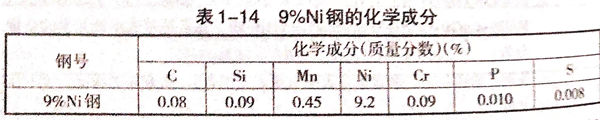

9%Ni鋼的(de)化學成分如表(biao)1-14所示

鋼中(zhong)(zhong)鎳含量(liang)對韌(ren)性(xing)(xing)有很大影響,隨(sui)著鎳含量(liang)的提(ti)高(gao),脆性(xing)(xing)轉變,溫(wen)(wen)度不斷(duan)下(xia)降(jiang),而(er)韌(ren)性(xing)(xing)提(ti)高(gao)。鋼中(zhong)(zhong)碳(tan)含量(liang)增大,其韌(ren)性(xing)(xing)下(xia)降(jiang),低(di)溫(wen)(wen)轉變溫(wen)(wen)度升高(gao),焊(han)接(jie)性(xing)(xing)惡化。鋼中(zhong)(zhong)硅(gui)是重要的脫氧(yang)(yang)劑,但又容易形成夾(jia)雜物(wu)而(er)危害韌(ren)性(xing)(xing)。錳可以細化晶粒,又可提(ti)高(gao)Mn/C比,提(ti)高(gao)韌(ren)性(xing)(xing),降(jiang)低(di)低(di)溫(wen)(wen)轉變溫(wen)(wen)度。氧(yang)(yang)是降(jiang)低(di)韌(ren)性(xing)(xing)、提(ti)高(gao)低(di)溫(wen)(wen)轉變溫(wen)(wen)度的元素,因此必(bi)須控制(zhi)。磷不僅與氧(yang)(yang)有類似的作用,即降(jiang)低(di)韌(ren)性(xing)(xing),提(ti)高(gao)脆性(xing)(xing)轉變溫(wen)(wen)度,而(er)且還(huan)惡化焊(han)接(jie)性(xing)(xing),所以必(bi)須嚴格(ge)控制(zhi)。