為了正(zheng)確(que)支(zhi)承管(guan)(guan)道(dao)(dao),滿足(zu)管(guan)(guan)道(dao)(dao)補償、熱位移和(he)防(fang)止(zhi)管(guan)(guan)道(dao)(dao)振動,防(fang)止(zhi)管(guan)(guan)道(dao)(dao)對(dui)設(she)備產生推力(li)等(deng)要求(qiu),管(guan)(guan)道(dao)(dao)敷設(she)應(ying)正(zheng)確(que)設(she)計和(he)施工管(guan)(guan)道(dao)(dao)的支(zhi)架和(he)吊架。管(guan)道支(zhi)架(jia)和(he)(he)吊架的(de)形式和(he)(he)結構(gou)很多,按用途分為滑(hua)動支(zhi)架、導向滑(hua)動支(zhi)架、固定支(zhi)架和(he)(he)吊架等。

固(gu)(gu)定(ding)支(zhi)(zhi)架用于(yu)管(guan)(guan)道上不允許(xu)有任何位(wei)(wei)移的(de)(de)地方。固(gu)(gu)定(ding)支(zhi)(zhi)架要(yao)(yao)(yao)生(sheng)(sheng)根在(zai)牢(lao)固(gu)(gu)的(de)(de)房屋結(jie)構(gou)或(huo)專設的(de)(de)結(jie)構(gou)物上。為防止(zhi)管(guan)(guan)道因受熱伸(shen)長而變形和(he)產(chan)生(sheng)(sheng)應(ying)力(li)(li),均采(cai)取分(fen)段設置(zhi)固(gu)(gu)定(ding)支(zhi)(zhi)架,在(zai)兩個固(gu)(gu)定(ding)支(zhi)(zhi)架之(zhi)間(jian)設置(zhi)補償器(qi)自然(ran)(ran)補償的(de)(de)技術措(cuo)施(shi)。固(gu)(gu)定(ding)支(zhi)(zhi)架與補償器(qi)相互配(pei)套,才能使管(guan)(guan)道熱伸(shen)長變形產(chan)生(sheng)(sheng)的(de)(de)位(wei)(wei)移和(he)應(ying)力(li)(li)得到(dao)控(kong)制,以滿(man)足管(guan)(guan)道安全要(yao)(yao)(yao)求。固(gu)(gu)定(ding)支(zhi)(zhi)架除承(cheng)受管(guan)(guan)道的(de)(de)重力(li)(li)(自重、管(guan)(guan)內(nei)介(jie)質重量(liang)及(ji)保(bao)溫層重量(liang))外,一般還要(yao)(yao)(yao)受到(dao)以下三(san)個方面(mian)的(de)(de)軸(zhou)向推(tui)力(li)(li)。一是(shi)(shi)管(guan)(guan)道伸(shen)長移動時活動支(zhi)(zhi)架上的(de)(de)摩擦力(li)(li)產(chan)生(sheng)(sheng)的(de)(de)軸(zhou)向推(tui)力(li)(li);二(er)是(shi)(shi)補償器(qi)本身結(jie)構(gou)或(huo)自然(ran)(ran)補償管(guan)(guan)段在(zai)伸(shen)縮(suo)或(huo)變形時產(chan)生(sheng)(sheng)的(de)(de)彈性反力(li)(li)或(huo)摩擦力(li)(li);三(san)是(shi)(shi)管(guan)(guan)道內(nei)介(jie)質壓(ya)力(li)(li)作用于(yu)管(guan)(guan)道,形成對固(gu)(gu)定(ding)支(zhi)(zhi)架的(de)(de)軸(zhou)向推(tui)力(li)(li)。因此,在(zai)安裝(zhuang)固(gu)(gu)定(ding)支(zhi)(zhi)架時一定(ding)要(yao)(yao)(yao)按照設計的(de)(de)位(wei)(wei)置(zhi)和(he)制造結(jie)構(gou)進行(xing)施(shi)工(gong),防止(zhi)由于(yu)施(shi)工(gong)問題(ti)出(chu)現固(gu)(gu)定(ding)支(zhi)(zhi)架被推(tui)倒或(huo)位(wei)(wei)移的(de)(de)事故。

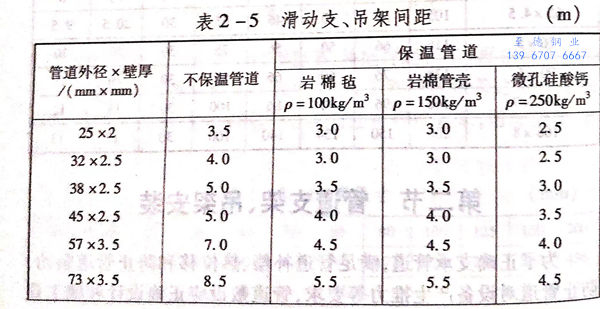

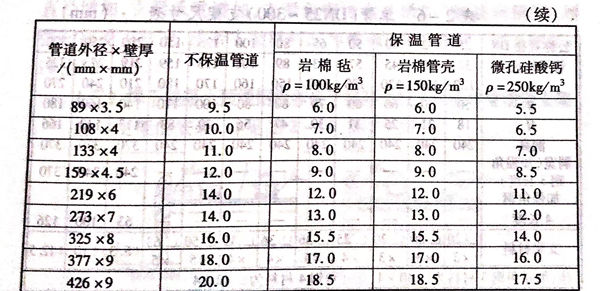

滑動支(zhi)架(jia)(jia)和一般(ban)吊架(jia)(jia)是用(yong)在管道(dao)無垂(chui)直(zhi)位移或垂(chui)直(zhi)位移極小(xiao)(xiao)的(de)(de)(de)(de)(de)地(di)方。其中(zhong)吊架(jia)(jia)用(yong)于不(bu)便安裝(zhuang)支(zhi)架(jia)(jia)的(de)(de)(de)(de)(de)地(di)方。支(zhi)、吊架(jia)(jia)的(de)(de)(de)(de)(de)間(jian)距應(ying)合理擔(dan)負管道(dao)荷重,并保證管道(dao)不(bu)產(chan)生彎曲(qu)。滑動支(zhi)架(jia)(jia)、吊架(jia)(jia)的(de)(de)(de)(de)(de)最大間(jian)距見(jian)表2-5所示。在安裝(zhuang)中(zhong),應(ying)按施工(gong)圖等(deng)要求施工(gong),考慮(lv)到安裝(zhuang)具體位置的(de)(de)(de)(de)(de)便利,支(zhi)架(jia)(jia)間(jian)距應(ying)小(xiao)(xiao)于表2-5的(de)(de)(de)(de)(de)規定值。

為減少(shao)管(guan)道(dao)在支(zhi)架(jia)上位移時的(de)摩擦力,對滑動支(zhi)架(jia),可采(cai)用在管(guan)道(dao)與(yu)支(zhi)架(jia)托板之間墊(dian)上摩擦系數小的(de)墊(dian)片,或(huo)采(cai)用滾珠支(zhi)架(jia)、滾柱支(zhi)架(jia)。這兩種支(zhi)架(jia)結(jie)構較復雜,一般用在介質溫(wen)度高(gao)和(he)管(guan)徑較大的(de)管(guan)道(dao)上。

導向滑(hua)動(dong)(dong)支(zhi)(zhi)架也稱為導向支(zhi)(zhi)架,它是只允(yun)許管(guan)道(dao)(dao)作軸向伸縮移動(dong)(dong)的(de)滑(hua)動(dong)(dong)支(zhi)(zhi)架。一(yi)般用(yong)于(yu)套筒(tong)補償器、波紋管(guan)補償器的(de)兩側,確保(bao)管(guan)道(dao)(dao)沿中(zhong)心線(xian)位移,以便(bian)補償器安全運行。在方(fang)(fang)形(xing)補償器兩側10R~15R距離處(其中(zhong)R為方(fang)(fang)形(xing)補償器彎管(guan)的(de)彎曲(qu)半徑),宜裝導向支(zhi)(zhi)架,以避免產生(sheng)橫(heng)向彎曲(qu)而影響管(guan)道(dao)(dao)的(de)穩定(ding)性。在鑄鐵閥件的(de)兩側,一(yi)般應裝導向支(zhi)(zhi)架,使鑄鐵件少受彎矩(ju)作用(yong)。

彈(dan)簧(huang)支架(jia)、彈(dan)簧(huang)吊架(jia)用于管(guan)道具有垂直(zhi)位(wei)移(yi)的(de)(de)地方(fang)。它是用彈(dan)簧(huang)的(de)(de)壓縮或伸長來吸收管(guan)道垂直(zhi)位(wei)移(yi)的(de)(de)。

支(zhi)(zhi)架(jia)安裝在室(shi)內要依靠磚墻(qiang)、混凝土(tu)柱、梁、樓(lou)板等重結構(gou),用預(yu)埋支(zhi)(zhi)架(jia)或預(yu)埋件和支(zhi)(zhi)架(jia)焊接等方法加(jia)以固(gu)定。現將常用方法和支(zhi)(zhi)架(jia)材料分述于下。