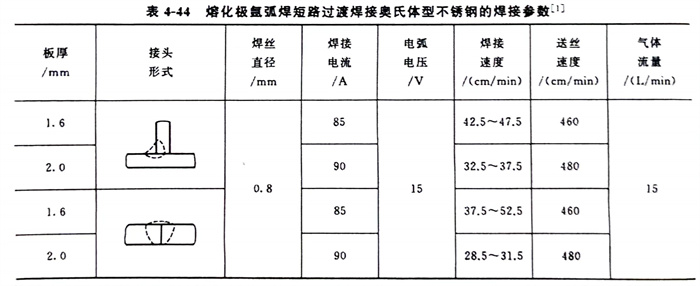

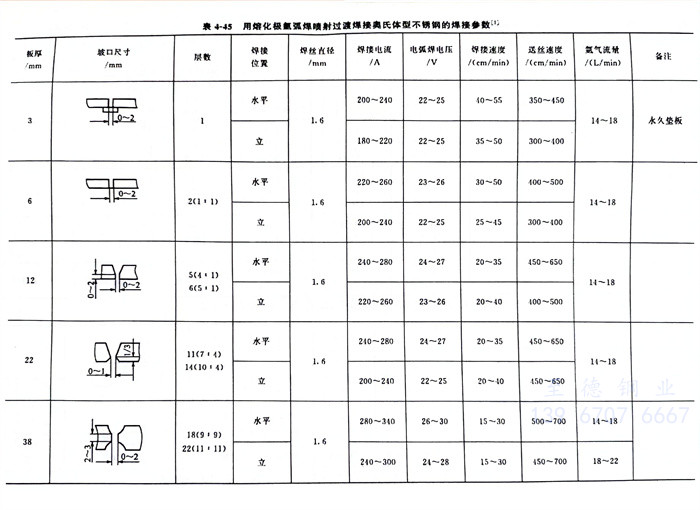

熔化極惰性氣體保護焊的惰性氣體,通常采用氬氣。該焊接工藝已開始在許多領域中得到使用,其中以機械操作的縱縫焊應用最多。焊接時選擇直流反極性電源,以短路過渡和噴射過渡的熔滴形式進行操作,用熔化極氬弧焊短路過渡焊接奧氏體(ti)不銹鋼的焊接參數見表4-44,用熔化極氬弧焊噴射過渡焊接奧氏體型不銹鋼的焊接參數見表4-45。

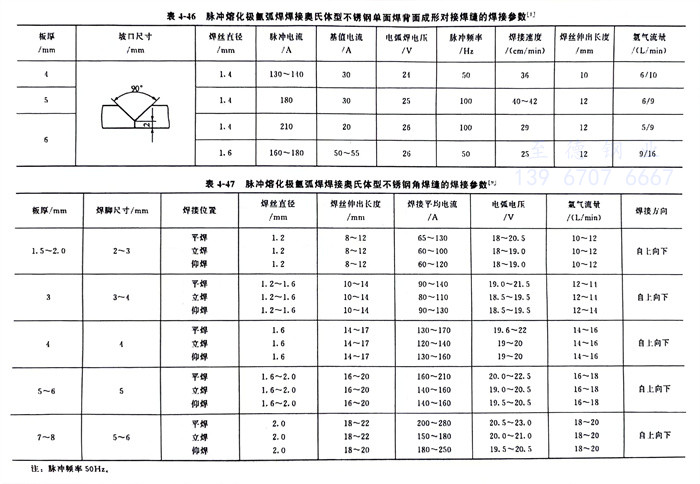

在熔(rong)(rong)化(hua)(hua)極(ji)(ji)(ji)氬(ya)(ya)氣保護焊(han)(han)(han)的(de)基礎上加入(ru)(ru)脈沖電(dian)流即(ji)成(cheng)脈沖熔(rong)(rong)化(hua)(hua)極(ji)(ji)(ji)氬(ya)(ya)弧(hu)焊(han)(han)(han),它(ta)不僅具(ju)有(you)熔(rong)(rong)化(hua)(hua)極(ji)(ji)(ji)氬(ya)(ya)氣保護焊(han)(han)(han)的(de)所有(you)特點,同(tong)時(shi)能(neng)(neng)控制(zhi)焊(han)(han)(han)接(jie)(jie)熱(re)輸(shu)入(ru)(ru),控制(zhi)金屬熔(rong)(rong)池(chi),使焊(han)(han)(han)縫(feng)正反(fan)面(mian)(mian)成(cheng)形(xing)良好,實(shi)現單面(mian)(mian)焊(han)(han)(han)背(bei)面(mian)(mian)成(cheng)形(xing)。表(biao)4-46為脈沖熔(rong)(rong)化(hua)(hua)極(ji)(ji)(ji)氬(ya)(ya)弧(hu)焊(han)(han)(han)的(de)單面(mian)(mian)焊(han)(han)(han)背(bei)面(mian)(mian)成(cheng)形(xing)對接(jie)(jie)焊(han)(han)(han)縫(feng)的(de)焊(han)(han)(han)接(jie)(jie)參(can)數。表(biao)4-47為脈沖熔(rong)(rong)化(hua)(hua)極(ji)(ji)(ji)氬(ya)(ya)弧(hu)焊(han)(han)(han)焊(han)(han)(han)接(jie)(jie)角焊(han)(han)(han)縫(feng)的(de)焊(han)(han)(han)接(jie)(jie)參(can)數。在焊(han)(han)(han)接(jie)(jie)同(tong)樣厚(hou)度(du)的(de)材料時(shi),焊(han)(han)(han)接(jie)(jie)熱(re)輸(shu)入(ru)(ru)比非脈沖熔(rong)(rong)化(hua)(hua)極(ji)(ji)(ji)焊(han)(han)(han)小,相應地減少了(le)熱(re)影響區,有(you)利于提(ti)高(gao)耐腐蝕性能(neng)(neng);同(tong)時(shi)減少了(le)焊(han)(han)(han)接(jie)(jie)應力與(yu)變形(xing)。脈沖電(dian)流的(de)熱(re)循環(huan)對金屬熔(rong)(rong)池(chi)能(neng)(neng)起到攪拌作(zuo)用,有(you)利于細(xi)化(hua)(hua)焊(han)(han)(han)縫(feng)結晶(jing),降低產(chan)生裂紋的(de)傾向(xiang)。此外(wai),這種焊(han)(han)(han)接(jie)(jie)方法(fa)可以減輕勞動強(qiang)度(du),提(ti)高(gao)生產(chan)效(xiao)率。