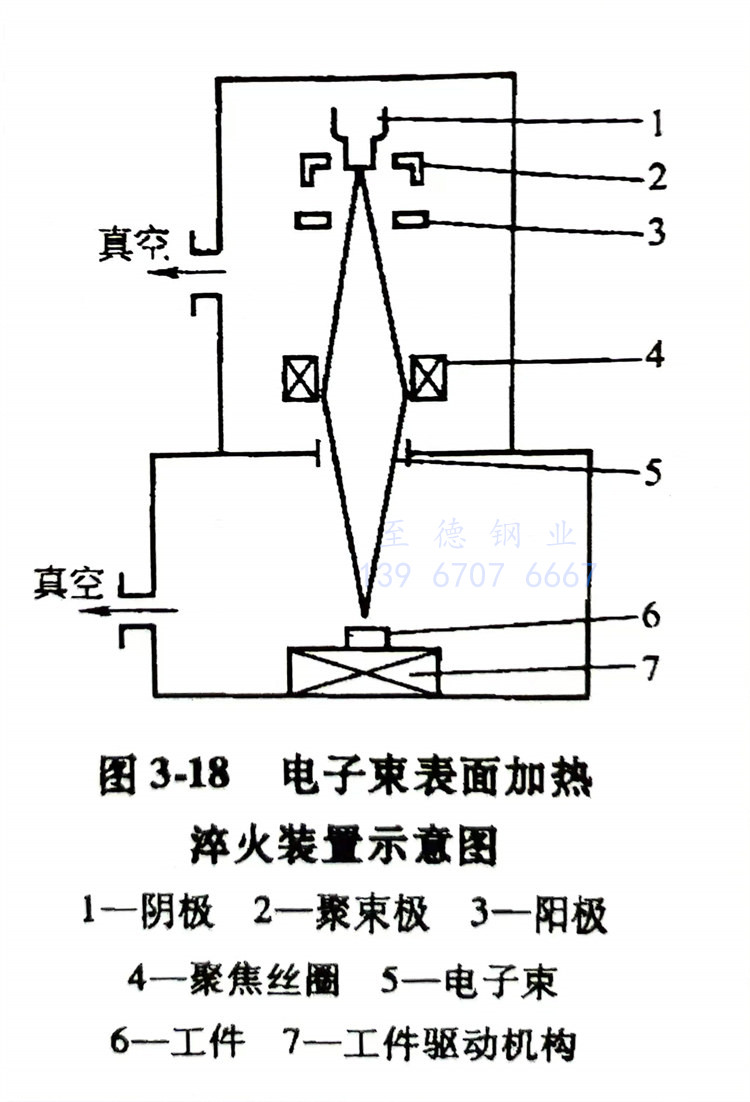

電(dian)(dian)(dian)子(zi)(zi)(zi)束(shu)(shu)表(biao)面強化是利用(yong)(yong)高(gao)能量密度的電(dian)(dian)(dian)子(zi)(zi)(zi)束(shu)(shu)加熱(re)進(jin)行(xing)表(biao)面淬火的新技術。電(dian)(dian)(dian)子(zi)(zi)(zi)束(shu)(shu)加熱(re)可以達到106~108W/c㎡的能量密度。圖3-18所示(shi)為電(dian)(dian)(dian)子(zi)(zi)(zi)束(shu)(shu)表(biao)面加熱(re)淬火裝置示(shi)意(yi)圖。利用(yong)(yong)電(dian)(dian)(dian)子(zi)(zi)(zi)束(shu)(shu)亦(yi)可實(shi)現相變硬(ying)化、熔化、凝固和表(biao)面合金化。電(dian)(dian)(dian)子(zi)(zi)(zi)束(shu)(shu)是由(you)陰極(燈絲(si))發出的電(dian)(dian)(dian)子(zi)(zi)(zi),通過高(gao)電(dian)(dian)(dian)壓環形陽極加速,并聚焦(jiao)成束(shu)(shu)使電(dian)(dian)(dian)子(zi)(zi)(zi)束(shu)(shu)流打擊(ji)金屬(shu)表(biao)面,達到加熱(re)的效果。

由(you)于高能(neng)量(liang)(liang)密度(du)(du)的電(dian)子束是在極短的時間(jian)內打(da)擊金屬表(biao)(biao)面(mian),所(suo)以使熱(re)量(liang)(liang)在表(biao)(biao)面(mian)逸(yi)散(san)的表(biao)(biao)面(mian)溫度(du)(du),就可以達到相變溫度(du)(du)范圍(wei)。當(dang)被(bei)加熱(re)表(biao)(biao)面(mian)吸(xi)收(shou)的熱(re)量(liang)(liang)很(hen)快地被(bei)底(di)層材料吸(xi)收(shou)而冷(leng)卻(que)時,就可以完成淬火冷(leng)卻(que)過程,從(cong)而產生有效的自行淬火。

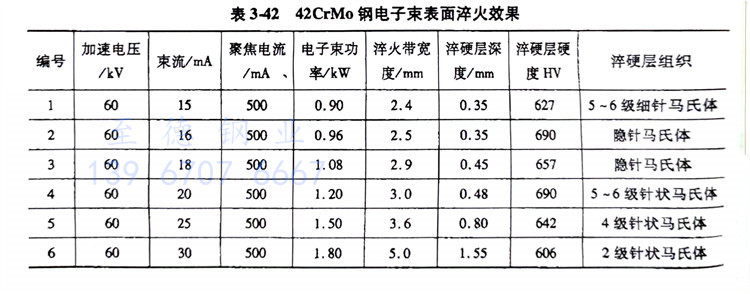

和(he)激光(guang)熱(re)(re)處(chu)理(li)相比(bi)(bi),電子(zi)束(shu)熱(re)(re)處(chu)理(li)的(de)缺點是(shi)模(mo)具必須(xu)放(fang)在(zai)真空室內,裝卸不方便。但(dan)是(shi)電子(zi)束(shu)熱(re)(re)處(chu)理(li)的(de)加熱(re)(re)效率比(bi)(bi)激光(guang)高,不需(xu)要激光(guang)熱(re)(re)處(chu)理(li)的(de)“表(biao)面黑化”過程。凡激光(guang)能對準(zhun)的(de)表(biao)面都可(ke)(ke)以利用電子(zi)束(shu)加熱(re)(re),電子(zi)束(shu)的(de)快速加熱(re)(re),使(shi)零件(jian)變形極小,無需(xu)后續的(de)校正工作,淬火后的(de)金相組(zu)織可(ke)(ke)獲得(de)細晶結構。表(biao)3-42所(suo)列為42CrMo鋼電子(zi)束(shu)表(biao)面淬火的(de)效果(guo)。