一(yi)、凝(ning)固(gu)收縮

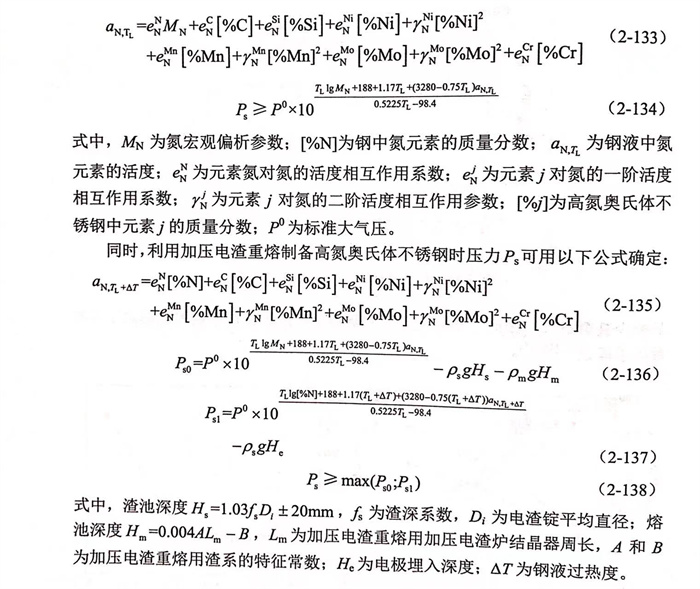

凝(ning)固過(guo)程中(zhong),液(ye)相(xiang)向(xiang)(xiang)固相(xiang)轉(zhuan)變發生(sheng)的(de)(de)(de)體收縮,加大了(le)氮(dan)氣孔形成的(de)(de)(de)敏感性,這主要是因為(wei)凝(ning)固收縮促(cu)進了(le)液(ye)相(xiang)穿過(guo)枝晶網(wang)狀結構或其(qi)他(ta)補縮通道向(xiang)(xiang)疏松(song)流動(dong)的(de)(de)(de)補縮行為(wei),導(dao)致了(le)疏松(song)與(yu)其(qi)附近區(qu)域之間產生(sheng)了(le)新(xin)的(de)(de)(de)壓力梯(ti)度,梯(ti)度方向(xiang)(xiang)為(wei)補縮流動(dong)的(de)(de)(de)反(fan)方向(xiang)(xiang),即VP。根據(ju)質量守(shou)恒和達西(xi)定(ding)律可知(zhi):

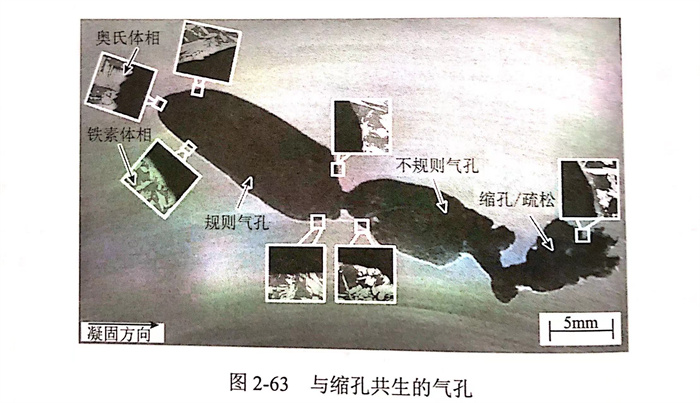

以21.5Cr5Mn1.5Ni0.25N含氮雙相鋼(gang)D1鑄錠為例,心部處疏松和(he)(he)氣(qi)(qi)(qi)(qi)孔(kong)(kong)(kong)(kong)共存(cun)的(de)形貌如圖2-63所示。由(you)疏松導致的(de)不規(gui)(gui)(gui)則(ze)(ze)(ze)(ze)氣(qi)(qi)(qi)(qi)孔(kong)(kong)(kong)(kong)與規(gui)(gui)(gui)則(ze)(ze)(ze)(ze)氣(qi)(qi)(qi)(qi)孔(kong)(kong)(kong)(kong)之間最大的(de)區別在于,不規(gui)(gui)(gui)則(ze)(ze)(ze)(ze)氣(qi)(qi)(qi)(qi)孔(kong)(kong)(kong)(kong)內壁(bi)凹凸不平,而(er)規(gui)(gui)(gui)則(ze)(ze)(ze)(ze)氣(qi)(qi)(qi)(qi)孔(kong)(kong)(kong)(kong)內壁(bi)光滑。規(gui)(gui)(gui)則(ze)(ze)(ze)(ze)氣(qi)(qi)(qi)(qi)孔(kong)(kong)(kong)(kong)、不規(gui)(gui)(gui)則(ze)(ze)(ze)(ze)氣(qi)(qi)(qi)(qi)孔(kong)(kong)(kong)(kong)以及疏松縮(suo)孔(kong)(kong)(kong)(kong)依次沿凝(ning)固方(fang)向(xiang)分(fen)布(bu),規(gui)(gui)(gui)則(ze)(ze)(ze)(ze)氣(qi)(qi)(qi)(qi)泡(pao)初始形成位置為單一奧(ao)(ao)氏(shi)體(ti)相。隨著(zhu)凝(ning)固的(de)進行,在規(gui)(gui)(gui)則(ze)(ze)(ze)(ze)氣(qi)(qi)(qi)(qi)孔(kong)(kong)(kong)(kong)完全(quan)閉合(he)之前,由(you)于疏松引起的(de)鋼(gang)液(ye)(ye)靜壓力Pm降低,促進了氣(qi)(qi)(qi)(qi)孔(kong)(kong)(kong)(kong)的(de)進一步生長,不規(gui)(gui)(gui)則(ze)(ze)(ze)(ze)氣(qi)(qi)(qi)(qi)孔(kong)(kong)(kong)(kong)開始形成和(he)(he)長大。眾所周(zhou)知,疏松是(shi)凝(ning)固體(ti)積(ji)縮(suo)無法得到(dao)枝(zhi)晶(jing)間液(ye)(ye)體(ti)補縮(suo)所導致的(de),那(nei)么不規(gui)(gui)(gui)則(ze)(ze)(ze)(ze)氣(qi)(qi)(qi)(qi)孔(kong)(kong)(kong)(kong)周(zhou)圍的(de)相分(fen)布(bu)和(he)(he)基體(ti)完全(quan)相同,即奧(ao)(ao)氏(shi)體(ti)相和(he)(he)鐵素體(ti)相交替分(fen)布(bu),與規(gui)(gui)(gui)則(ze)(ze)(ze)(ze)氣(qi)(qi)(qi)(qi)孔(kong)(kong)(kong)(kong)周(zhou)圍相分(fen)布(bu)存(cun)在差異。

此外,對柱(zhu)狀鑄(zhu)(zhu)(zhu)錠而(er)言,凝固末期由于發達枝(zhi)晶(jing)網狀結構的(de)形成,凝固收縮得不(bu)到液相(xiang)補(bu)充的(de)位置往往處(chu)于中心(xin)軸(zhou)線(xian)位置附近(jin),那么D1~D4鑄(zhu)(zhu)(zhu)錠中不(bu)規則氣(qi)孔大多數分布在鑄(zhu)(zhu)(zhu)錠中心(xin)軸(zhou)線(xian)位置處(chu),如(ru)圖2-50所示。不(bu)受疏松(song)影響的(de)規則氣(qi)孔形狀近(jin)似(si)橢圓形,且多數分布在靠近(jin)鑄(zhu)(zhu)(zhu)錠邊部的(de)位置。此外,鋼(gang)液靜壓力Pm隨著鑄(zhu)(zhu)(zhu)錠高度的(de)增加而(er)減小,因此氣(qi)孔的(de)數量(liang)和尺寸(cun)均隨鑄(zhu)(zhu)(zhu)錠高度增加而(er)大體呈(cheng)現(xian)出增加的(de)趨勢(圖2-50)。

二、主要合金(jin)元素(su)和凝固(gu)壓力(li)

1. 氮

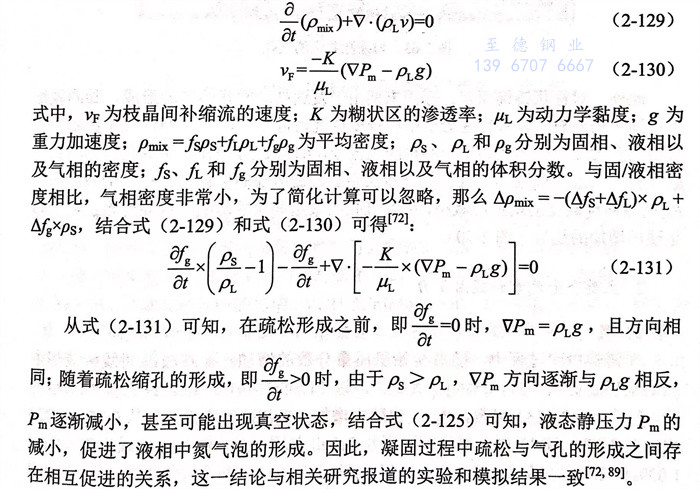

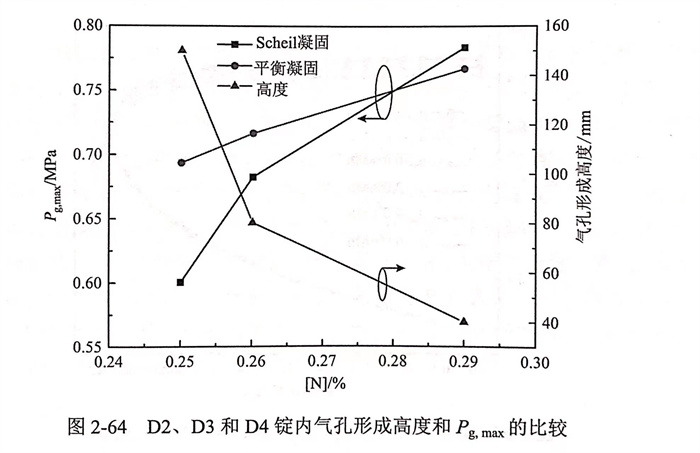

在(zai)鑄(zhu)(zhu)錠凝固(gu)過程中(zhong),隨著初(chu)始氮質量分(fen)數(shu)(shu)的(de)增(zeng)加(jia)(jia),氮在(zai)枝晶間殘余(yu)液相(xiang)中(zhong)的(de)富集程度更加(jia)(jia)嚴重,[%N]1iq值更大(da)(da)。以(yi)21.5Cr5Mn1.5Ni0.25N含(han)氮雙相(xiang)鋼為例,結合式(2-123)可(ke)得,Pg,max也(ye)隨之(zhi)增(zeng)加(jia)(jia)。當初(chu)始氮質量分(fen)數(shu)(shu)從0.25%(D2)增(zeng)加(jia)(jia)至0.29%(D4)時,對平衡凝固(gu)和Scheil凝固(gu)而言(yan),[%N]ig的(de)最大(da)(da)值分(fen)別為1.03%和1.51%(圖2-51),Pg,max的(de)增(zeng)量分(fen)別為0.07MPa和0.18MPa(如圖2-64所示)。由氣(qi)泡形(xing)成時的(de)壓(ya)力關系(xi)可(ke)知(zhi),P.,max的(de)增(zeng)加(jia)(jia)意味(wei)著液相(xiang)中(zhong)氮氣(qi)泡形(xing)成的(de)概率增(zeng)大(da)(da),表明增(zeng)加(jia)(jia)初(chu)始氮質量分(fen)數(shu)(shu)大(da)(da)幅度提(ti)高(gao)了鑄(zhu)(zhu)錠內出現氮氣(qi)孔缺陷的(de)可(ke)能性。

為(wei)了驗證(zheng)理論計算結果(guo),對D2、D3和D4鑄錠(ding)內氮(dan)氣孔(kong)的分(fen)(fen)(fen)布狀態(tai)進行實驗分(fen)(fen)(fen)析,D2、D3和D4凝固壓力(li)均為(wei)0.1MPa,其氮(dan)質(zhi)量(liang)(liang)分(fen)(fen)(fen)數分(fen)(fen)(fen)別(bie)為(wei)0.25%、0.26%和0.29%,氣孔(kong)形(xing)成高度(du)從150mm降(jiang)至40mm,如(ru)圖2-64所示(shi)。因(yin)此(ci),Pg,max隨著初始氮(dan)質(zhi)量(liang)(liang)分(fen)(fen)(fen)數的增加而增大,液相中氮(dan)氣泡(pao)形(xing)成難(nan)度(du)減小,氮(dan)氣孔(kong)易(yi)于在鑄錠(ding)內形(xing)成。

2. 錳

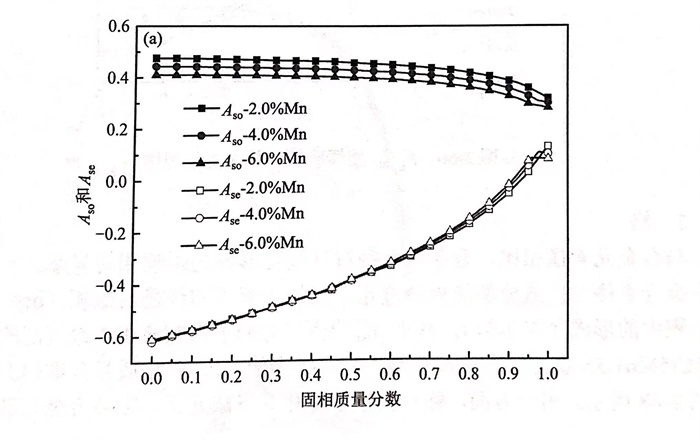

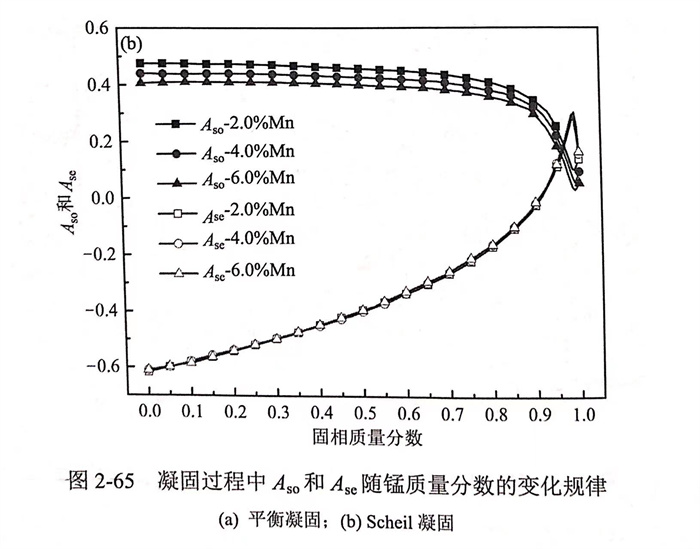

研究發現[19,25,95],部分合(he)(he)(he)金(jin)元(yuan)素(su)(su)(如(ru)(ru)錳(meng)和鉻)能(neng)夠(gou)提(ti)高液相(xiang)(xiang)(xiang)中(zhong)(zhong)(zhong)(zhong)氮(dan)(dan)的(de)(de)溶解度,減小Aso值(zhi);其中(zhong)(zhong)(zhong)(zhong)錳(meng)等合(he)(he)(he)金(jin)元(yuan)素(su)(su)在(zai)(zai)凝(ning)固(gu)(gu)過程(cheng)中(zhong)(zhong)(zhong)(zhong)還能(neng)促進(jin)富(fu)(fu)氮(dan)(dan)相(xiang)(xiang)(xiang)的(de)(de)形成,減小枝晶間液相(xiang)(xiang)(xiang)中(zhong)(zhong)(zhong)(zhong)氮(dan)(dan)的(de)(de)富(fu)(fu)集,緩(huan)解氮(dan)(dan)偏析,降低(di)Ase值(zhi)。如(ru)(ru)果合(he)(he)(he)金(jin)元(yuan)素(su)(su)能(neng)夠(gou)減小Aso與(yu)Ase的(de)(de)總和,那么提(ti)高鋼中(zhong)(zhong)(zhong)(zhong)該合(he)(he)(he)金(jin)元(yuan)素(su)(su)的(de)(de)質量(liang)分數有助(zhu)于(yu)抑(yi)制氮(dan)(dan)氣泡在(zai)(zai)殘余液相(xiang)(xiang)(xiang)中(zhong)(zhong)(zhong)(zhong)形成。合(he)(he)(he)金(jin)元(yuan)素(su)(su)錳(meng)提(ti)高液相(xiang)(xiang)(xiang)中(zhong)(zhong)(zhong)(zhong)氮(dan)(dan)質量(liang)分數的(de)(de)同時(shi),還有助(zhu)于(yu)富(fu)(fu)氮(dan)(dan)相(xiang)(xiang)(xiang)(如(ru)(ru)奧(ao)氏體相(xiang)(xiang)(xiang)γ和hcp相(xiang)(xiang)(xiang))在(zai)(zai)凝(ning)固(gu)(gu)過程(cheng)中(zhong)(zhong)(zhong)(zhong)的(de)(de)形成。以21.5Cr5Mn1.5Ni0.25N含氮(dan)(dan)雙相(xiang)(xiang)(xiang)鋼D1鑄(zhu)(zhu)錠為例,在(zai)(zai)平衡凝(ning)固(gu)(gu)和Scheil凝(ning)固(gu)(gu)中(zhong)(zhong)(zhong)(zhong),增(zeng)加(jia)合(he)(he)(he)金(jin)元(yuan)素(su)(su)錳(meng)均能(neng)同時(shi)降低(di)Aso和Ase的(de)(de)值(zhi),如(ru)(ru)圖(tu)2-65所示。與(yu)此(ci)同時(shi),結合(he)(he)(he)式(2-123),隨著合(he)(he)(he)金(jin)元(yuan)素(su)(su)錳(meng)質量(liang)分數增(zeng)加(jia)而大幅度減小,如(ru)(ru)圖(tu)2-66所示。因此(ci)增(zeng)加(jia)鑄(zhu)(zhu)錠中(zhong)(zhong)(zhong)(zhong)合(he)(he)(he)金(jin)元(yuan)素(su)(su)錳(meng)的(de)(de)質量(liang)分數有助(zhu)于(yu)抑(yi)制液相(xiang)(xiang)(xiang)中(zhong)(zhong)(zhong)(zhong)氮(dan)(dan)氣泡的(de)(de)形成,減少或消除21.5Cr5Mn1.5Ni0.25N 含氮(dan)(dan)雙相(xiang)(xiang)(xiang)鋼中(zhong)(zhong)(zhong)(zhong)氮(dan)(dan)氣孔缺(que)陷,該結論與(yu)Young等報(bao)道的(de)(de)一致。

3. 鉻

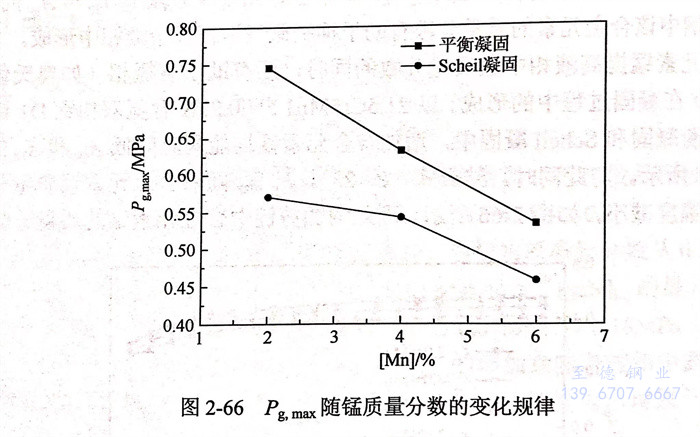

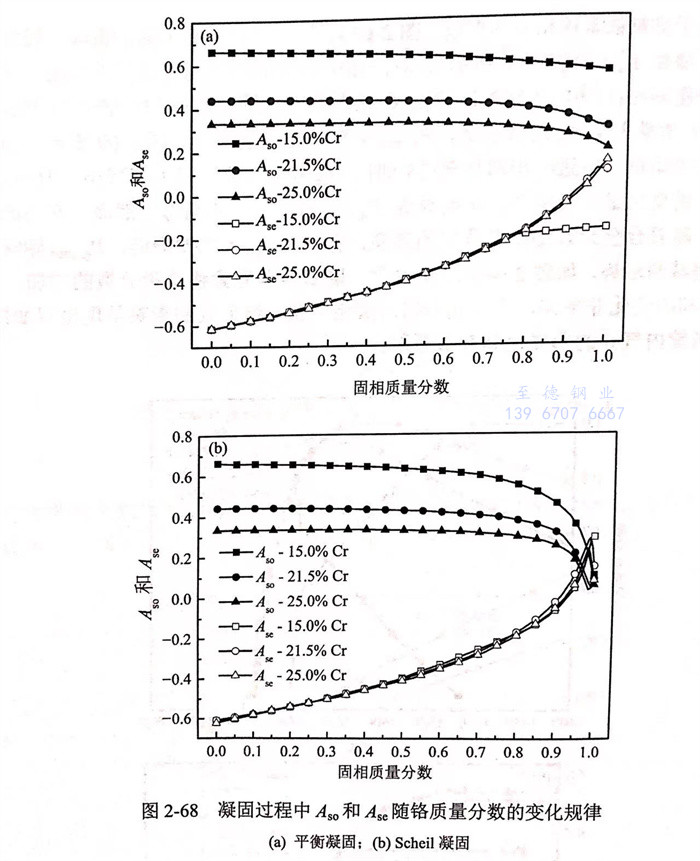

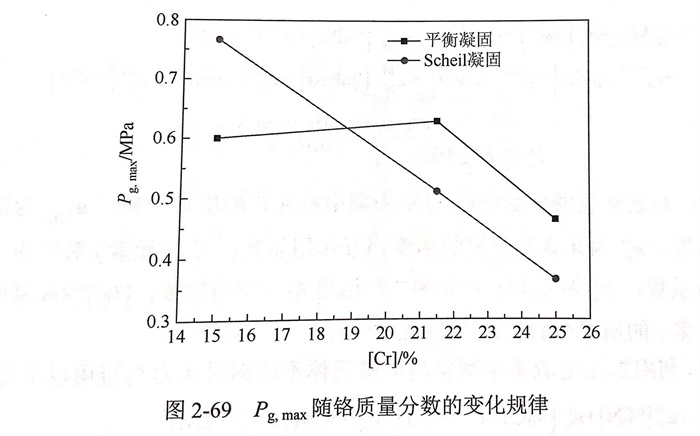

與合(he)(he)金(jin)元(yuan)(yuan)(yuan)(yuan)(yuan)素(su)(su)(su)錳(meng)相(xiang)(xiang)(xiang)(xiang)比,合(he)(he)金(jin)元(yuan)(yuan)(yuan)(yuan)(yuan)素(su)(su)(su)鉻(ge)(ge)(ge)(ge)對(dui)(dui)氮(dan)氣(qi)(qi)孔(kong)形(xing)(xing)(xing)成(cheng)的(de)(de)(de)(de)(de)影(ying)響(xiang)相(xiang)(xiang)(xiang)(xiang)對(dui)(dui)復雜。一方(fang)面,增(zeng)(zeng)(zeng)加合(he)(he)金(jin)元(yuan)(yuan)(yuan)(yuan)(yuan)素(su)(su)(su)鉻(ge)(ge)(ge)(ge)的(de)(de)(de)(de)(de)質量(liang)(liang)分(fen)(fen)數(shu)(shu)(shu)能(neng)提(ti)高液(ye)相(xiang)(xiang)(xiang)(xiang)中(zhong)(zhong)氮(dan)的(de)(de)(de)(de)(de)溶(rong)解(jie)度和(he)(he)(he)促進(jin)富氮(dan)相(xiang)(xiang)(xiang)(xiang)(hcp 相(xiang)(xiang)(xiang)(xiang))在(zai)凝固(gu)過程中(zhong)(zhong)的(de)(de)(de)(de)(de)形(xing)(xing)(xing)成(cheng)(圖2-67),減小Aso的(de)(de)(de)(de)(de)值,有(you)(you)助(zhu)于(yu)抑制(zhi)液(ye)相(xiang)(xiang)(xiang)(xiang)中(zhong)(zhong)氮(dan)氣(qi)(qi)泡(pao)的(de)(de)(de)(de)(de)形(xing)(xing)(xing)成(cheng)。以(yi)21.5Cr5Mn1.5Ni0.25N 含氮(dan)雙(shuang)(shuang)相(xiang)(xiang)(xiang)(xiang)鋼D1鑄錠(ding)為例,Aso隨(sui)鉻(ge)(ge)(ge)(ge)質量(liang)(liang)分(fen)(fen)數(shu)(shu)(shu)的(de)(de)(de)(de)(de)變化(hua)規律,如圖2-68所(suo)示(shi)。另一方(fang)面,鉻(ge)(ge)(ge)(ge)作為鐵(tie)素(su)(su)(su)體相(xiang)(xiang)(xiang)(xiang)8形(xing)(xing)(xing)成(cheng)元(yuan)(yuan)(yuan)(yuan)(yuan)素(su)(su)(su),提(ti)高合(he)(he)金(jin)元(yuan)(yuan)(yuan)(yuan)(yuan)素(su)(su)(su)鉻(ge)(ge)(ge)(ge)的(de)(de)(de)(de)(de)質量(liang)(liang)分(fen)(fen)數(shu)(shu)(shu)有(you)(you)利于(yu)貧氮(dan)鐵(tie)素(su)(su)(su)體相(xiang)(xiang)(xiang)(xiang)8的(de)(de)(de)(de)(de)形(xing)(xing)(xing)成(cheng)(圖2-67),從(cong)而(er)加劇液(ye)相(xiang)(xiang)(xiang)(xiang)中(zhong)(zhong)氮(dan)的(de)(de)(de)(de)(de)富集,增(zeng)(zeng)(zeng)大氮(dan)的(de)(de)(de)(de)(de)偏析,增(zeng)(zeng)(zeng)加Ase(如圖2-68所(suo)示(shi)),對(dui)(dui)液(ye)相(xiang)(xiang)(xiang)(xiang)中(zhong)(zhong)氮(dan)氣(qi)(qi)泡(pao)的(de)(de)(de)(de)(de)形(xing)(xing)(xing)成(cheng)具有(you)(you)促進(jin)作用。這(zhe)種矛盾在(zai)平衡凝固(gu)過程中(zhong)(zhong)較(jiao)為突出(chu),當(dang)合(he)(he)金(jin)元(yuan)(yuan)(yuan)(yuan)(yuan)素(su)(su)(su)鉻(ge)(ge)(ge)(ge)的(de)(de)(de)(de)(de)質量(liang)(liang)分(fen)(fen)數(shu)(shu)(shu)從(cong)15%增(zeng)(zeng)(zeng)至21.5%時(shi),由于(yu)Ase的(de)(de)(de)(de)(de)增(zeng)(zeng)(zeng)量(liang)(liang)大于(yu)Aso的(de)(de)(de)(de)(de)減小量(liang)(liang),Pg,max呈現(xian)增(zeng)(zeng)(zeng)大的(de)(de)(de)(de)(de)趨(qu)勢,如圖2-69所(suo)示(shi);當(dang)合(he)(he)金(jin)元(yuan)(yuan)(yuan)(yuan)(yuan)素(su)(su)(su)鉻(ge)(ge)(ge)(ge)的(de)(de)(de)(de)(de)質量(liang)(liang)分(fen)(fen)數(shu)(shu)(shu)進(jin)一步增(zeng)(zeng)(zeng)加至25%時(shi),Ase和(he)(he)(he)Aso分(fen)(fen)別(bie)增(zeng)(zeng)(zeng)大和(he)(he)(he)減小,但與Ase相(xiang)(xiang)(xiang)(xiang)比Aso的(de)(de)(de)(de)(de)變化(hua)量(liang)(liang)十分(fen)(fen)明顯,進(jin)而(er)導致Pg出(chu)現(xian)減小的(de)(de)(de)(de)(de)趨(qu)勢。然而(er),在(zai)Scheil凝固(gu)中(zhong)(zhong),隨(sui)著合(he)(he)金(jin)元(yuan)(yuan)(yuan)(yuan)(yuan)素(su)(su)(su)鉻(ge)(ge)(ge)(ge)質量(liang)(liang)分(fen)(fen)數(shu)(shu)(shu)的(de)(de)(de)(de)(de)提(ti)高,有(you)(you)助(zhu)于(yu)Aso大幅度降低,Pg,max始終保持單(dan)調(diao)遞減的(de)(de)(de)(de)(de)趨(qu)勢,如圖2-69所(suo)示(shi)。總(zong)之(zhi),隨(sui)著合(he)(he)金(jin)元(yuan)(yuan)(yuan)(yuan)(yuan)素(su)(su)(su)鉻(ge)(ge)(ge)(ge)質量(liang)(liang)分(fen)(fen)數(shu)(shu)(shu)的(de)(de)(de)(de)(de)增(zeng)(zeng)(zeng)加,Aso與Ase之(zhi)和(he)(he)(he)的(de)(de)(de)(de)(de)變化(hua)非單(dan)調(diao),合(he)(he)金(jin)元(yuan)(yuan)(yuan)(yuan)(yuan)素(su)(su)(su)鉻(ge)(ge)(ge)(ge)對(dui)(dui)液(ye)相(xiang)(xiang)(xiang)(xiang)中(zhong)(zhong)氮(dan)氣(qi)(qi)泡(pao)形(xing)(xing)(xing)成(cheng)的(de)(de)(de)(de)(de)影(ying)響(xiang)呈現(xian)出(chu)雙(shuang)(shuang)面性(xing),同樣對(dui)(dui)鑄錠(ding)內氣(qi)(qi)孔(kong)的(de)(de)(de)(de)(de)形(xing)(xing)(xing)成(cheng)也(ye)具有(you)(you)雙(shuang)(shuang)面性(xing)。

4. 凝固(gu)壓(ya)力

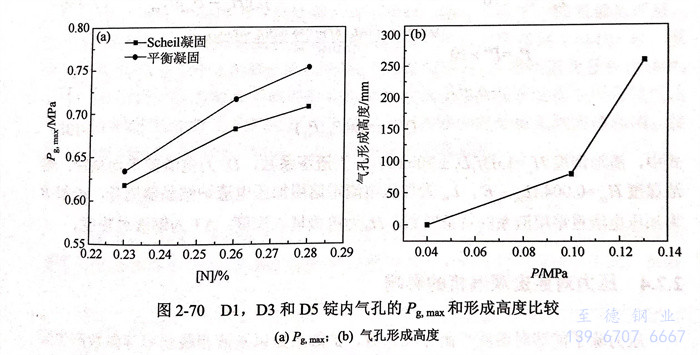

以21.5Cr5Mn1.5Ni0.25N 含氮雙(shuang)相鋼D1鑄錠為例,D1、D3和D5鑄錠的凝固壓力分別為0.04MPa、0.10MPa和0.13MPa,氮的質量分數分別為0.23%、0.26%和0.28%.隨著氮質量分數從0.23%(D1)增加至0.28%(D5)時,P.g,max在平衡凝固中從0.634MPa 增加至0.753MPa,在Scheil凝固中從0.618MPa增至0.707MPa,如圖2-70(a)所示。在不考慮凝固壓力對氮氣孔形成的影響時,基于初始氮質量分數對氮氣孔形成的影響規律,與D1和D3相比,D5鑄錠內氮氣孔缺陷最為嚴重。然而,當凝固壓力從0.04MPa(D1)增加至0.13MPa(D5)時,氮氣孔形成高度從0mm增加至260mm[圖2-70(b)],同時氮氣孔數量也明顯減少甚至消失。因此,增加凝固壓力是抑制和消除鑄錠中氮氣孔缺陷十分有效的手段之一。

然而(er),壓(ya)(ya)(ya)力(li)過(guo)高(gao)將會加(jia)速(su)設備(bei)損耗,提高(gao)生(sheng)產成(cheng)本(ben)且易引(yin)發生(sheng)產事故,影響生(sheng)產的(de)安全和(he)順(shun)利運行。因(yin)此,利用加(jia)壓(ya)(ya)(ya)冶金(jin)技術制(zhi)備(bei)高(gao)氮奧氏體(ti)不銹鋼過(guo)程中,需要合理地控制(zhi)壓(ya)(ya)(ya)力(li)。利用加(jia)壓(ya)(ya)(ya)感應爐(lu)制(zhi)備(bei)高(gao)氮奧氏體(ti)不銹鋼時,壓(ya)(ya)(ya)力(li)P6可用以(yi)下公(gong)式確定: