一、固(gu)相無擴(kuo)散(san)和完全擴(kuo)散(san)效應

含鉻鎳(nie)不銹鋼在凝固過程中(zhong),根據(ju)元(yuan)素鉻和鎳(nie)當量濃度比凝固模式可分為以下四(si)類(lei)。

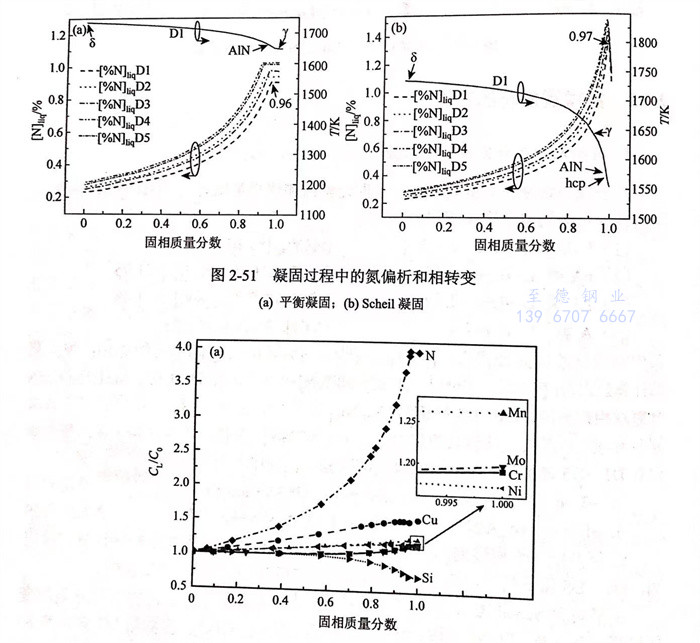

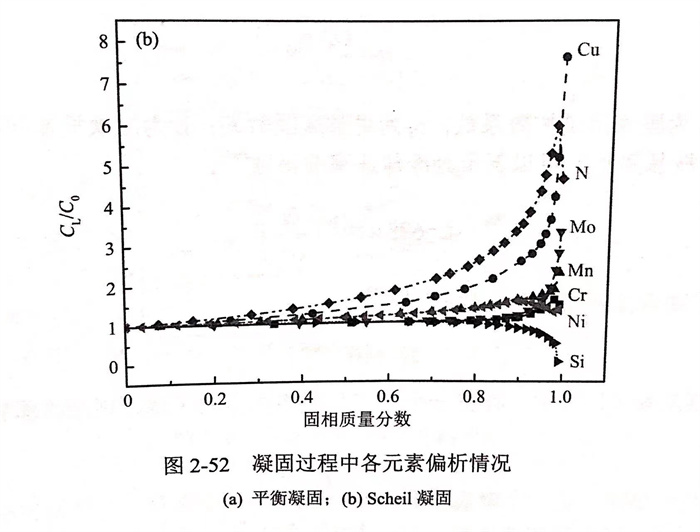

在(zai)(zai)(zai)平(ping)(ping)(ping)衡(heng)和(he)Scheil凝(ning)(ning)固(gu)(gu)過(guo)程中(zhong),D1~D5鑄(zhu)錠內,[%N]uiq隨固(gu)(gu)相(xiang)(xiang)(xiang)質(zhi)(zhi)量(liang)分(fen)數(shu)(shu)(shu)的(de)(de)(de)變化趨勢(shi)完全(quan)一(yi)致(zhi)(zhi)。以D1為例,對平(ping)(ping)(ping)衡(heng)凝(ning)(ning)固(gu)(gu)而(er)(er)(er)言[圖(tu)2-51(a)],貧氮(dan)(dan)(dan)(dan)相(xiang)(xiang)(xiang)(鐵素(su)體(ti)(ti)相(xiang)(xiang)(xiang)δ)的(de)(de)(de)不(bu)斷(duan)形(xing)(xing)成[78],導(dao)致(zhi)(zhi)氮(dan)(dan)(dan)(dan)在(zai)(zai)(zai)殘余液相(xiang)(xiang)(xiang)中(zhong)大(da)量(liang)富集(ji)(ji),[%N]iq快速(su)增(zeng)(zeng)大(da),直(zhi)到(dao)固(gu)(gu)相(xiang)(xiang)(xiang)質(zhi)(zhi)量(liang)分(fen)數(shu)(shu)(shu)達(da)到(dao)0.96左(zuo)右(you)。隨后,富氮(dan)(dan)(dan)(dan)相(xiang)(xiang)(xiang)(奧氏體(ti)(ti)相(xiang)(xiang)(xiang)γ和(he)AIN)持續形(xing)(xing)成,由于(yu)富氮(dan)(dan)(dan)(dan)相(xiang)(xiang)(xiang)中(zhong)氮(dan)(dan)(dan)(dan)的(de)(de)(de)平(ping)(ping)(ping)衡(heng)分(fen)配系(xi)數(shu)(shu)(shu)和(he)溶解度(du)均大(da)于(yu)貧氮(dan)(dan)(dan)(dan)相(xiang)(xiang)(xiang)[25,771,致(zhi)(zhi)使(shi)[%N]iq的(de)(de)(de)增(zeng)(zeng)長速(su)率陡降(jiang),致(zhi)(zhi)使(shi)[%N]iq在(zai)(zai)(zai)隨后的(de)(de)(de)凝(ning)(ning)固(gu)(gu)過(guo)程中(zhong)幾(ji)乎保持不(bu)變。氮(dan)(dan)(dan)(dan)、鎳和(he)錳一(yi)起(qi)富集(ji)(ji)在(zai)(zai)(zai)富氮(dan)(dan)(dan)(dan)相(xiang)(xiang)(xiang)γ奧氏體(ti)(ti)中(zhong),且(qie)富氮(dan)(dan)(dan)(dan)相(xiang)(xiang)(xiang)γ奧氏體(ti)(ti)中(zhong)氮(dan)(dan)(dan)(dan)質(zhi)(zhi)量(liang)分(fen)數(shu)(shu)(shu)明(ming)顯(xian)大(da)于(yu)貧氮(dan)(dan)(dan)(dan)鐵素(su)體(ti)(ti)相(xiang)(xiang)(xiang)δ,差值可達(da)0.28%.在(zai)(zai)(zai)Scheil凝(ning)(ning)固(gu)(gu)過(guo)程中(zhong),[%N]1iq變化規律如圖(tu)2-51(b)所示,當固(gu)(gu)相(xiang)(xiang)(xiang)質(zhi)(zhi)量(liang)分(fen)數(shu)(shu)(shu)小于(yu)0.97時,[%N]iq隨著固(gu)(gu)相(xiang)(xiang)(xiang)質(zhi)(zhi)量(liang)分(fen)數(shu)(shu)(shu)的(de)(de)(de)增(zeng)(zeng)加(jia)而(er)(er)(er)快速(su)增(zeng)(zeng)大(da),隨后[%N]iq增(zeng)(zeng)長速(su)率陡降(jiang),同時[%N]iiq也隨之發生斷(duan)裂(lie)式下降(jiang),明(ming)顯(xian)區別于(yu)平(ping)(ping)(ping)衡(heng)凝(ning)(ning)固(gu)(gu)。與平(ping)(ping)(ping)衡(heng)凝(ning)(ning)固(gu)(gu)相(xiang)(xiang)(xiang)比,由于(yu)Scheil凝(ning)(ning)固(gu)(gu)固(gu)(gu)相(xiang)(xiang)(xiang)無擴散,導(dao)致(zhi)(zhi)氮(dan)(dan)(dan)(dan)、錳、鉻和(he)鉬(mu)在(zai)(zai)(zai)殘余液相(xiang)(xiang)(xiang)中(zhong)的(de)(de)(de)富集(ji)(ji)程度(du)明(ming)顯(xian)大(da)于(yu)其在(zai)(zai)(zai)平(ping)(ping)(ping)衡(heng)凝(ning)(ning)固(gu)(gu)中(zhong)的(de)(de)(de)富集(ji)(ji)(圖(tu)2-52),促進(jin)了氮(dan)(dan)(dan)(dan)化物[密排六(liu)方(hcp)相(xiang)(xiang)(xiang)]的(de)(de)(de)形(xing)(xing)成,進(jin)而(er)(er)(er)致(zhi)(zhi)使(shi)[%N]iq發生斷(duan)裂(lie)式下降(jiang)[圖(tu)2-51(b)]。

凝固過程中相(xiang)的(de)種類以(yi)及成(cheng)(cheng)分(fen)(fen)對殘(can)余液相(xiang)中氮(dan)偏(pian)(pian)析(xi)有(you)(you)至關(guan)重要(yao)的(de)影響。富氮(dan)相(xiang)(奧(ao)氏體(ti)相(xiang)γ、AIN和hcp相(xiang))的(de)持(chi)續形成(cheng)(cheng),減小了(le)枝(zhi)晶干(gan)與(yu)(yu)枝(zhi)晶間(jian)殘(can)余液相(xiang)之間(jian)氮(dan)質量分(fen)(fen)數的(de)差距(ju),進而減輕了(le)枝(zhi)晶間(jian)殘(can)余液相(xiang)中氮(dan)偏(pian)(pian)析(xi),有(you)(you)助于(yu)(yu)避免鋼液中氮(dan)氣泡大(da)范圍地(di)形成(cheng)(cheng)和長大(da),與(yu)(yu)Makaya等(deng)的(de)研究一致。因此,富氮(dan)相(xiang)(奧(ao)氏體(ti)相(xiang)γ、AIN和hcp相(xiang))的(de)形成(cheng)(cheng)有(you)(you)利于(yu)(yu)抑制鋼中氮(dan)氣孔的(de)形成(cheng)(cheng)。

二、固相反擴散效(xiao)應

碳(tan)、氮(dan)等間(jian)隙原(yuan)子(zi),其固(gu)相(xiang)擴(kuo)散系數較大,其實際微(wei)觀(guan)偏(pian)析程度處于固(gu)相(xiang)無擴(kuo)散和固(gu)相(xiang)完全擴(kuo)散條件(jian)元素偏(pian)析之間(jian),為了(le)更好地貼合(he)實際情況,基于C-K模(mo)型,可做以(yi)下假(jia)設,建立一種適合(he)高氮(dan)鋼(gang)凝固(gu)溶(rong)質再(zai)分配的模(mo)型。

(1)Fe-N相圖的液相線(xian)(xian)和(he)固相線(xian)(xian)是直線(xian)(xian)。

(2)液相(xiang)完全(quan)擴散,固相(xiang)不(bu)完全(quan)擴散。

(3)固(gu)-液(ye)界(jie)面的推進速度呈拋(pao)物線狀。

(4)溶質元素(su)在固相中的擴散存(cun)在邊界層。

(5)溶質橫向分布均勻。

(6)忽略其他元素的偏析(xi)。

(7)不(bu)考慮凝固過程中氮析出的損失。

高氮(dan)鋼在凝固過程(cheng)中,隨著凝固的(de)進行(xing),凝固界面固相氮(dan)濃度(du)可表示為

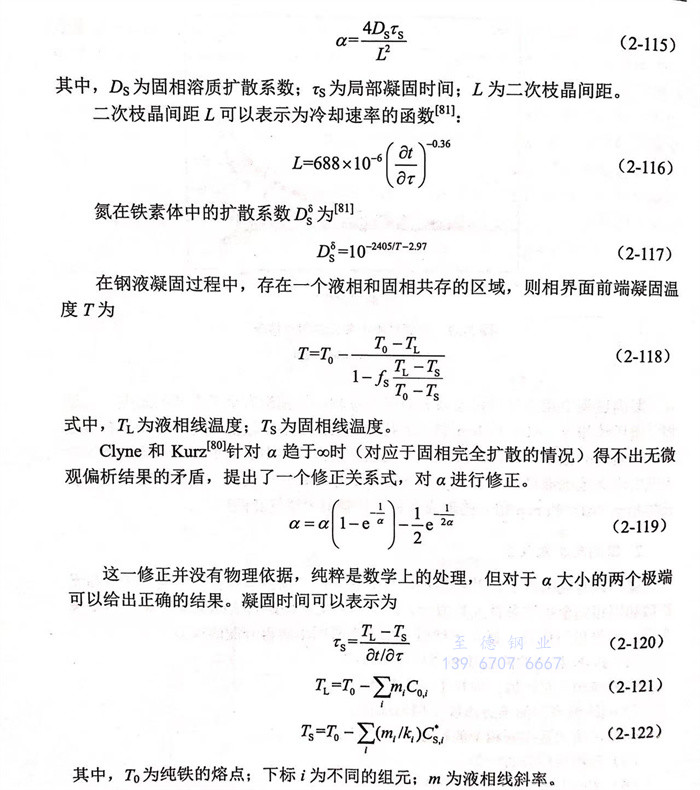

從(cong)圖中可以看出(chu),隨著凝固的進行,氮濃度逐(zhu)漸增大,且固相率越(yue)大時,氮濃度增加得越(yue)快。當前沿氮濃度超(chao)過其(qi)飽和值時,便會有(you)氮氣(qi)泡(pao)析出(chu)的可能。從(cong)微觀(guan)偏(pian)(pian)析方(fang)程(2-114)可以看出(chu),影響微觀(guan)偏(pian)(pian)析的因素只有(you)凝固參數α和偏(pian)(pian)析參數k,下(xia)面就這兩(liang)方(fang)面進行討論分析。

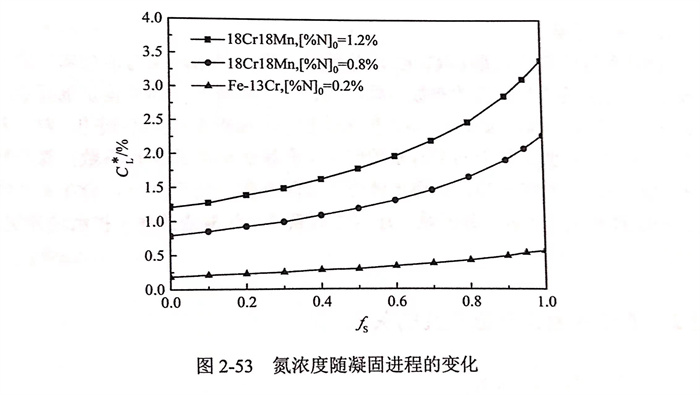

1. 凝固參數α

由凝固參(can)數的(de)(de)表達式可(ke)(ke)以(yi)看出,a值的(de)(de)大小(xiao)與氮在(zai)該鋼中(zhong)(zhong)的(de)(de)固相(xiang)擴散系數、鋼的(de)(de)固相(xiang)線溫度(du)、液相(xiang)線溫度(du)及冷卻強度(du)有關。對(dui)于(yu)特定的(de)(de)鋼種,α值是在(zai)一定范圍(wei)的(de)(de)。如高(gao)(gao)氮鋼,α為2~3[82](圖2-54陰影(ying)(ying)分),偏析(xi)(xi)(xi)程度(du)Dp可(ke)(ke)以(yi)達到5%,α越(yue)小(xiao),偏析(xi)(xi)(xi)越(yue)嚴重,在(zai)高(gao)(gao)氮鋼熔煉過程中(zhong)(zhong)應(ying)該盡量(liang)避免氮偏析(xi)(xi)(xi)。但對(dui)于(yu)修正后的(de)(de)α,α值的(de)(de)變化對(dui)偏析(xi)(xi)(xi)程度(du)影(ying)(ying)響較小(xiao)。

2. 分(fen)配系數k

分(fen)配系(xi)(xi)(xi)(xi)數(shu)(shu)(shu)(shu)(shu)的(de)表達(da)式是k=Cs/C,是凝(ning)固(gu)過程(cheng)中固(gu)相濃度與液相濃度的(de)比值。它(ta)(ta)是表征(zheng)元素(su)是否易偏析(xi)的(de)參數(shu)(shu)(shu)(shu)(shu)。碳(tan)、硫(liu)、磷等(deng)都是非常(chang)容(rong)易偏析(xi)的(de)元素(su),且這(zhe)些元素(su)在(zai)(zai)(zai)不(bu)同的(de)固(gu)相(如(ru)8-Fe相、奧氏體(ti)相)中偏析(xi)系(xi)(xi)(xi)(xi)數(shu)(shu)(shu)(shu)(shu)是不(bu)同的(de)。對于要研究的(de)氮元素(su),它(ta)(ta)在(zai)(zai)(zai)奧氏體(ti)中的(de)偏析(xi)系(xi)(xi)(xi)(xi)數(shu)(shu)(shu)(shu)(shu)要大于在(zai)(zai)(zai)鐵素(su)體(ti)中的(de)偏析(xi)系(xi)(xi)(xi)(xi)數(shu)(shu)(shu)(shu)(shu),氮在(zai)(zai)(zai)鐵素(su)體(ti)中的(de)分(fen)配系(xi)(xi)(xi)(xi)數(shu)(shu)(shu)(shu)(shu)一(yi)般取(qu)0.38,在(zai)(zai)(zai)奧氏體(ti)中的(de)分(fen)配系(xi)(xi)(xi)(xi)數(shu)(shu)(shu)(shu)(shu)一(yi)般取(qu)0.48,分(fen)配系(xi)(xi)(xi)(xi)數(shu)(shu)(shu)(shu)(shu)越小,偏析(xi)程(cheng)度越嚴重。另(ling)外,分(fen)配系(xi)(xi)(xi)(xi)數(shu)(shu)(shu)(shu)(shu)還與凝(ning)固(gu)條件(如(ru)凝(ning)固(gu)速(su)率、擴散邊(bian)界層厚度)等(deng)相關(guan)。