21世紀原(yuan)(yuan)油(you)重(zhong)(zhong)(zhong)質(zhi)化(hua)(hua)和(he)劣質(zhi)化(hua)(hua)的(de)趨勢將越來越明顯,我國煉(lian)油(you)行業加(jia)(jia)(jia)工(gong)(gong)含(han)硫原(yuan)(yuan)油(you)和(he)重(zhong)(zhong)(zhong)質(zhi)原(yuan)(yuan)油(you)的(de)比(bi)例將越來越大。在煉(lian)油(you)廠含(han)硫重(zhong)(zhong)(zhong)質(zhi)原(yuan)(yuan)油(you)加(jia)(jia)(jia)工(gong)(gong)工(gong)(gong)藝流程的(de)選(xuan)擇和(he)配置上,可采(cai)用延遲焦化(hua)(hua)、渣油(you)加(jia)(jia)(jia)氫、重(zhong)(zhong)(zhong)油(you)催化(hua)(hua)裂化(hua)(hua)(RFCC)或相應的(de)組合工(gong)(gong)藝;對于產品(pin)精(jing)制(zhi)則普遍采(cai)用加(jia)(jia)(jia)氫精(jing)制(zhi)工(gong)(gong)藝,以滿足日益提高的(de)環(huan)保和(he)產品(pin)質(zhi)量的(de)要求。因此,在煉(lian)油(you)廠總的(de)加(jia)(jia)(jia)工(gong)(gong)流程中,各種臨氫工(gong)(gong)藝已(yi)日益成為煉(lian)油(you)廠主要的(de)加(jia)(jia)(jia)工(gong)(gong)手段。

工業上生產氫(qing)氣(qi)(qi)的(de)方法(fa)有很多(duo),如(ru)煤(mei)或焦炭的(de)水煤(mei)氣(qi)(qi)法(fa)、渣(zha)油或重油的(de)部分氧化法(fa)、輕(qing)烴水蒸(zheng)氣(qi)(qi)轉化法(fa)、煉油廠富氫(qing)氣(qi)(qi)體凈化分離法(fa)、甲醇為原料蒸(zheng)汽重整法(fa)以(yi)及(ji)電解(jie)水法(fa)等。而(er)輕(qing)烴水蒸(zheng)氣(qi)(qi)轉化法(fa)以(yi)其(qi)工藝成熟可靠、投資低廉、操作方便(bian)而(er)占主(zhu)導地位。就(jiu)全(quan)球范圍而(er)言,對于煉油企業,除從含(han)氫(qing)氣(qi)(qi)體中回收(shou)氫(qing)外,目前大約90%的(de)制氫(qing)裝置都采用烴類水蒸(zheng)氣(qi)(qi)轉化法(fa)。

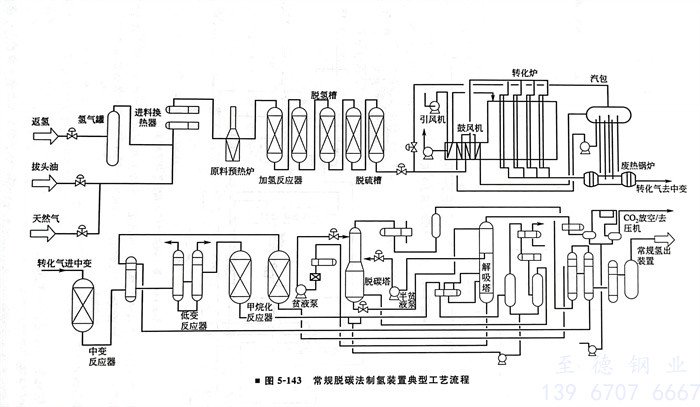

常規脫(tuo)碳法制(zhi)氫裝置典型工(gong)藝(yi)流程,如(ru)圖5-143所示。