1. 原油常減壓蒸餾裝置工藝流程簡介

石(shi)油(you)(you)煉(lian)制工(gong)(gong)業是國民(min)經(jing)濟(ji)的(de)(de)重(zhong)要支柱產(chan)業,其(qi)產(chan)品被廣泛用于工(gong)(gong)業、農業、及交(jiao)通運輸(shu)和(he)(he)國防建設(she)等領(ling)域。催化(hua)裂(lie)化(hua)(FCC)作為石(shi)油(you)(you)煉(lian)制企業的(de)(de)主(zhu)要生產(chan)裝置,在(zai)石(shi)油(you)(you)加工(gong)(gong)中占(zhan)有相當重(zhong)要的(de)(de)地位,是實(shi)現原(yuan)油(you)(you)深(shen)度(du)加工(gong)(gong)、提高輕質油(you)(you)收率、品質和(he)(he)經(jing)濟(ji)效益的(de)(de)有效途徑,催化(hua)裂(lie)化(hua)使(shi)原(yuan)油(you)(you)二次(ci)加工(gong)(gong)中重(zhong)要的(de)(de)加工(gong)(gong)過程,是液化(hua)石(shi)油(you)(you)氣、汽油(you)(you)、煤(mei)油(you)(you)和(he)(he)采油(you)(you)、柴油(you)(you)的(de)(de)主(zhu)

要(yao)生產手段,在煉油(you)廠(chang)中站有舉足輕重(zhong)的(de)地(di)位。傳統原(yuan)料(liao)采用原(yuan)油(you)蒸餾(liu)所得到的(de)重(zhong)質餾(liu)分油(you),主(zhu)要(yao)是直餾(liu)減壓(ya)餾(liu)分油(you)(VGO),也包括焦化(hua)(hua)重(zhong)餾(liu)分油(you)(CGO)。近(jin)二十(shi)年一(yi)些重(zhong)質油(you)或(huo)渣油(you)也作為(wei)催化(hua)(hua)裂(lie)化(hua)(hua)的(de)原(yuan)料(liao),例如減壓(ya)渣油(you)、溶劑(ji)脫瀝青(qing)油(you)、加氫處理的(de)重(zhong)油(you)等。

催(cui)化(hua)(hua)裂化(hua)(hua)的(de)(de)工(gong)藝原理是:反(fan)(fan)(fan)應物(wu)(蠟油(you)(you)、脫(tuo)瀝(li)青油(you)(you)、渣(zha)油(you)(you))在500℃左右、0.2~0.4MPa及(ji)(ji)與(yu)催(cui)化(hua)(hua)劑(ji)接觸的(de)(de)作用下發(fa)生(sheng)裂化(hua)(hua)、異構化(hua)(hua)、環化(hua)(hua)、芳化(hua)(hua)、脫(tuo)氫化(hua)(hua)等諸多化(hua)(hua)學(xue)反(fan)(fan)(fan)應,反(fan)(fan)(fan)應物(wu)為(wei)汽油(you)(you)、輕柴油(you)(you)、重柴油(you)(you),副產(chan)(chan)物(wu)為(wei)干(gan)氣(qi)、焦炭、油(you)(you)漿等。催(cui)化(hua)(hua)劑(ji)理論上在反(fan)(fan)(fan)應過程中不(bu)損耗,而是引導(dao)裂化(hua)(hua)反(fan)(fan)(fan)應生(sheng)成更多所需的(de)(de)高辛(xin)烷值烴產(chan)(chan)品(pin)(pin)。催(cui)化(hua)(hua)裂化(hua)(hua)過程相(xiang)當的(de)(de)靈活(huo)性,允(yun)許制(zhi)造車(che)用和航空汽油(you)(you)以及(ji)(ji)粗柴油(you)(you)產(chan)(chan)量的(de)(de)變化(hua)(hua)來滿(man)足燃油(you)(you)市場的(de)(de)主要部分(fen)被轉化(hua)(hua)成汽油(you)(you)和低沸點產(chan)(chan)品(pin)(pin),通(tong)常(chang)(chang)這是一個單(dan)程操作。在裂化(hua)(hua)反(fan)(fan)(fan)應中,所生(sheng)產(chan)(chan)的(de)(de)焦炭被沉(chen)積在催(cui)化(hua)(hua)劑(ji)上,它(ta)明顯地(di)減少了(le)催(cui)化(hua)(hua)劑(ji)的(de)(de)活(huo)性,所以除去沉(chen)積物(wu)是非常(chang)(chang)必要的(de)(de),通(tong)常(chang)(chang)是通(tong)過燃燒(shao)方式使(shi)催(cui)化(hua)(hua)劑(ji)再生(sheng)來重新恢復其(qi)活(huo)性。

催(cui)化(hua)裂(lie)化(hua)采用(yong)哪(na)種技術是由需要多生產(chan)哪(na)種產(chan)品確(que)定的,催(cui)化(hua)裂(lie)化(hua)“家(jia)族工藝”包括多產(chan)汽油和液化(hua)氣的技術(MGG、ARGG)、提(ti)高輕(qing)質油和柴油產(chan)率的技術(TSRFCC),降(jiang)低烯(xi)(xi)烴含量的技術(SR20、MIP、MGD)、多產(chan)丙烯(xi)(xi)的技術(DCC、CPP、TMP)、多產(chan)異構烯(xi)(xi)烴的技術(MIO)等。

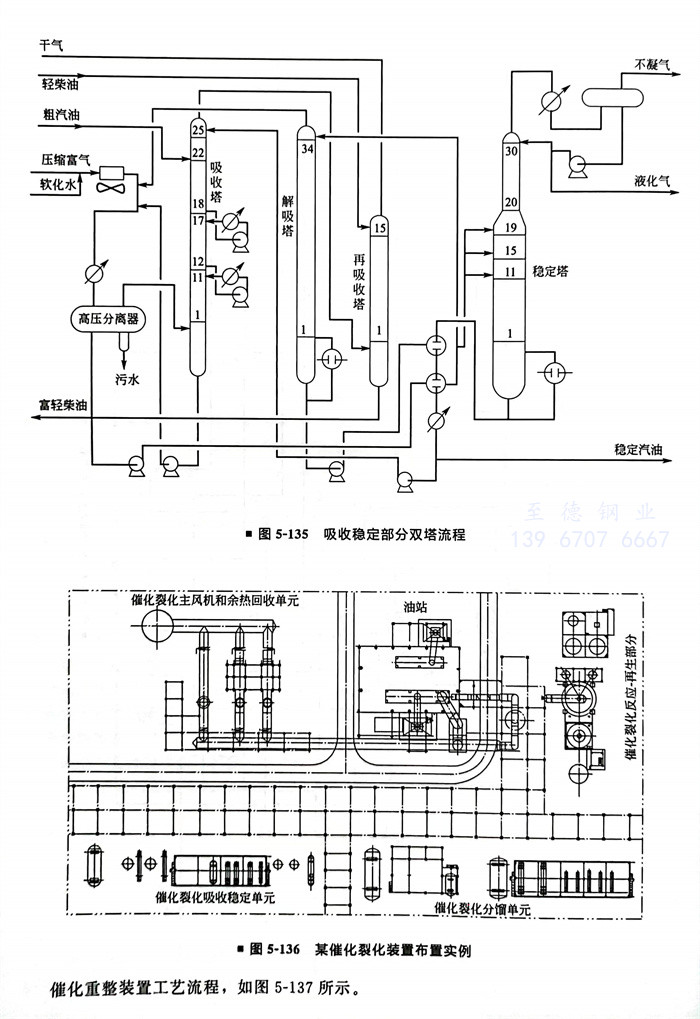

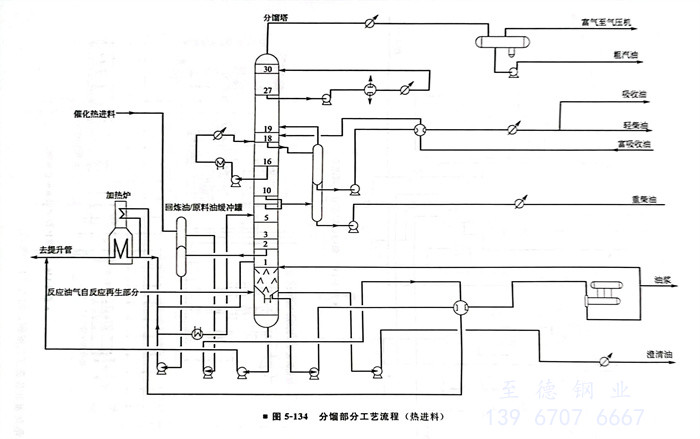

典型工藝流程(cheng)簡圖(tu),如(ru)圖(tu)5-134和圖(tu)5-135所示(shi)。

2. 某催化裂化裝置布(bu)置實例(圖5-136)