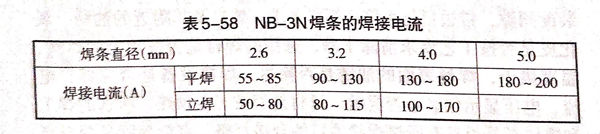

3.5%鎳鋼(gang)通(tong)(tong)過(guo)降(jiang)低(di)(di)(di)碳、硫、磷含量(liang),加入鎳等合(he)金成分,并通(tong)(tong)過(guo)熱(re)(re)處(chu)(chu)(chu)理(li)(li)細化晶粒,使(shi)(shi)其具有優良的(de)低(di)(di)(di)溫(wen)(wen)(wen)性(xing)(xing)能,被廣泛應(ying)(ying)(ying)用于(yu)(yu)乙(yi)烯、化肥、液化石油氣及(ji)煤氣工程中低(di)(di)(di)溫(wen)(wen)(wen)設備的(de)制(zhi)造。3.5%鎳鋼(gang)一(yi)(yi)般(ban)(ban)(ban)為正火(huo)或(huo)正火(huo)+回火(huo)狀態使(shi)(shi)用,其低(di)(di)(di)溫(wen)(wen)(wen)韌性(xing)(xing)較(jiao)穩定,顯(xian)微組織為鐵素體(ti)和珠光(guang)體(ti),使(shi)(shi)用溫(wen)(wen)(wen)度(du)達(da)-101℃.經調質處(chu)(chu)(chu)理(li)(li),其組織和低(di)(di)(di)溫(wen)(wen)(wen)韌性(xing)(xing)得到進一(yi)(yi)步(bu)改(gai)善(shan)(shan),最低(di)(di)(di)使(shi)(shi)用溫(wen)(wen)(wen)度(du)為-110℃.為避(bi)(bi)免由于(yu)(yu)過(guo)熱(re)(re)而使(shi)(shi)焊(han)(han)(han)(han)(han)縫及(ji)熱(re)(re)影(ying)響(xiang)區的(de)韌性(xing)(xing)惡(e)化,焊(han)(han)(han)(han)(han)接時(shi)焊(han)(han)(han)(han)(han)條(tiao)盡量(liang)不擺動,采(cai)陽(yang)焊(han)(han)(han)(han)(han)道(dao)(dao)、多道(dao)(dao)多層(ceng)焊(han)(han)(han)(han)(han),并嚴格控(kong)(kong)制(zhi)焊(han)(han)(han)(han)(han)接預熱(re)(re)溫(wen)(wen)(wen)度(du)及(ji)焊(han)(han)(han)(han)(han)道(dao)(dao)間(jian)溫(wen)(wen)(wen)度(du),一(yi)(yi)般(ban)(ban)(ban)控(kong)(kong)制(zhi)在(zai)50~100℃范圍內(nei),同(tong)時(shi)應(ying)(ying)(ying)采(cai)用小的(de)熱(re)(re)輸(shu)入施焊(han)(han)(han)(han)(han),焊(han)(han)(han)(han)(han)條(tiao)電(dian)弧焊(han)(han)(han)(han)(han)的(de)熱(re)(re)輸(shu)人應(ying)(ying)(ying)控(kong)(kong)制(zhi)在(zai)2.0kJ/mm以(yi)下(xia),熔化極氣體(ti)保(bao)護焊(han)(han)(han)(han)(han)的(de)熱(re)(re)輸(shu)入應(ying)(ying)(ying)控(kong)(kong)制(zhi)在(zai)2.5kJ/mm以(yi)下(xia)。由于(yu)(yu)3.5%鎳鋼(gang)中的(de)含碳量(liang)較(jiao)低(di)(di)(di),所以(yi)其淬(cui)硬傾(qing)向不大,一(yi)(yi)般(ban)(ban)(ban)可以(yi)不預熱(re)(re),但板厚在(zai)25mm以(yi)上,焊(han)(han)(han)(han)(han)件(jian)剛性(xing)(xing)較(jiao)大時(shi),焊(han)(han)(han)(han)(han)前(qian)要預熱(re)(re)到150℃左右,道(dao)(dao)間(jian)溫(wen)(wen)(wen)度(du)與預熱(re)(re)溫(wen)(wen)(wen)度(du)相(xiang)同(tong),鋼(gang)有應(ying)(ying)(ying)變(bian)時(shi)效傾(qing)向,當冷(leng)加工變(bian)形量(liang)在(zai)5%以(yi)上時(shi),要進行消(xiao)除應(ying)(ying)(ying)力熱(re)(re)處(chu)(chu)(chu)理(li)(li)改(gai)善(shan)(shan)韌性(xing)(xing)。該類鋼(gang)在(zai)焊(han)(han)(han)(han)(han)后(hou)消(xiao)除應(ying)(ying)(ying)力退火(huo)處(chu)(chu)(chu)理(li)(li)過(guo)程中,易產生回火(huo)脆性(xing)(xing)。為避(bi)(bi)免回火(huo)脆性(xing)(xing),建(jian)議(yi)(yi)采(cai)用4.5%Ni-0.2%Mo系焊(han)(han)(han)(han)(han)絲,用NB-3N焊(han)(han)(han)(han)(han)條(tiao)焊(han)(han)(han)(han)(han)接時(shi),建(jian)議(yi)(yi)采(cai)用表5-58規定的(de)焊(han)(han)(han)(han)(han)接電(dian)流,焊(han)(han)(han)(han)(han)后(hou)進行600~625℃熱(re)(re)處(chu)(chu)(chu)理(li)(li),有利(li)于(yu)(yu)收(shou)善(shan)(shan)焊(han)(han)(han)(han)(han)接接頭的(de)低(di)(di)(di)溫(wen)(wen)(wen)韌性(xing)(xing)。