美國不銹鋼管廠家成立于1910年,當時共有2套無縫軋管機,由曼氏穿孔機、聯合穿軋機、再加熱爐和精整機組組成。1913年增設張力減徑機,從而在1916~1920年這5年內生產冷拔不銹管坯而獲利甚豐,1920年開始改造,1923年聘用了Foren工程師,1931年接受了Foren建議開始制造并制成21機架軋管機,1932年投人試生產到1933年正式生產運行,1936年又對冷拔車間進行改造,1940年后轉向專業生產無縫不銹鋼管。

福(fu)倫(Foren)軋(ya)機是(shi)連(lian)(lian)續軋(ya)管(guan)(guan)機發(fa)展過(guo)(guo)程中的(de)(de)一(yi)個重要的(de)(de)中間軋(ya)機,是(shi)在美國進行正式生產的(de)(de)第一(yi)臺連(lian)(lian)續軋(ya)管(guan)(guan)機,機架(jia)X形,長芯(xin)棒插人穿孔(kong)坯與管(guan)(guan)子(zi)一(yi)起通過(guo)(guo)全部(bu)機架(jia),即將穿孔(kong)延(yan)伸(shen)成(cheng)管(guan)(guan)子(zi)。福(fu)倫軋(ya)管(guan)(guan)機共有21個機架(jia),由可變(bian)速的(de)(de)電機單驅動,按原設計,延(yan)伸(shen)率可高達7。

對連軋(ya)管機(ji)(ji)(ji)的(de)發展(zhan)來說,福(fu)(fu)倫軋(ya)機(ji)(ji)(ji)的(de)意義(yi)在于:采(cai)用直流電機(ji)(ji)(ji)單獨傳動以代替組(zu)傳動,為(wei)連軋(ya)管機(ji)(ji)(ji)的(de)進一步(bu)發展(zhan)奠定(ding)了新的(de)基礎,由此連軋(ya)管機(ji)(ji)(ji)進入了一個新階段,人們把(ba)福(fu)(fu)倫軋(ya)機(ji)(ji)(ji)稱為(wei)第二代連軋(ya)管機(ji)(ji)(ji)。

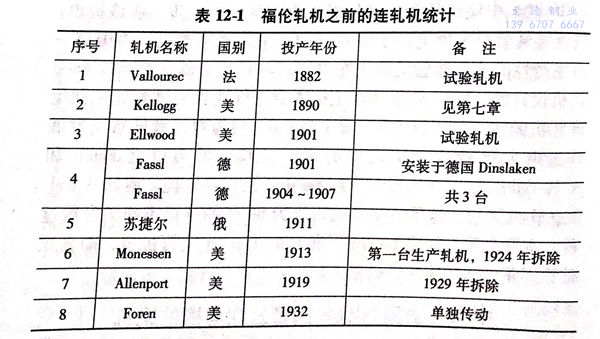

從連(lian)軋(ya)管(guan)(guan)機發展的全(quan)過程來看,福(fu)倫軋(ya)機是(shi)美(mei)國的第4臺(tai)連(lian)軋(ya)管(guan)(guan)機,世界范圍內的第11臺(tai)軋(ya)管(guan)(guan)機,可參(can)見表12-1所示。

1. Gary 不銹(xiu)鋼管(guan)廠(chang)連軋管(guan)機(ji)組

第(di)二次世界(jie)大戰后,Gary 不銹鋼(gang)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)廠(chang)(chang)的(de)(de)(de)(de)無(wu)縫鋼(gang)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)生產(chan)設(she)(she)備一(yi)直閑置不用(yong)。后來該廠(chang)(chang)利用(yong)停產(chan)這(zhe)一(yi)時機(ji)(ji)(ji)(ji)(ji)(ji),對1套軋(ya)(ya)(ya)(ya)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)機(ji)(ji)(ji)(ji)(ji)(ji)組(zu)(zu)進行了(le)(le)改造,安裝了(le)(le)連軋(ya)(ya)(ya)(ya)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)機(ji)(ji)(ji)(ji)(ji)(ji),并配(pei)以新(xin)的(de)(de)(de)(de)張(zhang)(zhang)力(li)(li)減徑(jing)(jing)機(ji)(ji)(ji)(ji)(ji)(ji),這(zhe)一(yi)新(xin)機(ji)(ji)(ji)(ji)(ji)(ji)組(zu)(zu)采用(yong)了(le)(le)和Lorain鋼(gang)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)廠(chang)(chang)進行試驗的(de)(de)(de)(de)相(xiang)同機(ji)(ji)(ji)(ji)(ji)(ji)組(zu)(zu)的(de)(de)(de)(de)許(xu)多新(xin)工(gong)藝。在平面布置上(shang)也(ye)包括了(le)(le)三輥(gun)軋(ya)(ya)(ya)(ya)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)機(ji)(ji)(ji)(ji)(ji)(ji)。根據(ju)當時的(de)(de)(de)(de)報(bao)告,張(zhang)(zhang)力(li)(li)減徑(jing)(jing)機(ji)(ji)(ji)(ji)(ji)(ji)尚(shang)未以全效(xiao)率(lv)軋(ya)(ya)(ya)(ya)管(guan)(guan)(guan)(guan)(guan)(guan)(guan),但已表明了(le)(le)它是能以低成(cheng)(cheng)本(ben)生產(chan)質量好(hao)的(de)(de)(de)(de)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)子(zi)的(de)(de)(de)(de)機(ji)(ji)(ji)(ji)(ji)(ji)組(zu)(zu),配(pei)置這(zhe)一(yi)機(ji)(ji)(ji)(ji)(ji)(ji)組(zu)(zu)或類似機(ji)(ji)(ji)(ji)(ji)(ji)組(zu)(zu)是生產(chan)小(xiao)口(kou)徑(jing)(jing)熱軋(ya)(ya)(ya)(ya)無(wu)縫鋼(gang)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)的(de)(de)(de)(de)最佳工(gong)藝。以全效(xiao)率(lv)運行時,從張(zhang)(zhang)減機(ji)(ji)(ji)(ji)(ji)(ji)軋(ya)(ya)(ya)(ya)出的(de)(de)(de)(de)速度(du)可達549m/min.Gary 廠(chang)(chang)連軋(ya)(ya)(ya)(ya)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)機(ji)(ji)(ji)(ji)(ji)(ji)組(zu)(zu)于1950年1月投產(chan),和三輥(gun)軋(ya)(ya)(ya)(ya)機(ji)(ji)(ji)(ji)(ji)(ji)并聯(lian)布置,生產(chan)外(wai)徑(jing)(jing)為25~89mm的(de)(de)(de)(de)鋼(gang)管(guan)(guan)(guan)(guan)(guan)(guan)(guan),薄壁管(guan)(guan)(guan)(guan)(guan)(guan)(guan)長度(du)為13.7m,厚壁管(guan)(guan)(guan)(guan)(guan)(guan)(guan)長度(du)為7.6m,機(ji)(ji)(ji)(ji)(ji)(ji)組(zu)(zu)中所(suo)設(she)(she)的(de)(de)(de)(de)穿(chuan)孔機(ji)(ji)(ji)(ji)(ji)(ji)是一(yi)般的(de)(de)(de)(de)曼(man)(man)內斯曼(man)(man)穿(chuan)孔機(ji)(ji)(ji)(ji)(ji)(ji),根據(ju)所(suo)軋(ya)(ya)(ya)(ya)鋼(gang)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)規格(ge)的(de)(de)(de)(de)不同,穿(chuan)孔坯可以送(song)(song)到(dao)連軋(ya)(ya)(ya)(ya)軋(ya)(ya)(ya)(ya)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)機(ji)(ji)(ji)(ji)(ji)(ji)上(shang),也(ye)可以送(song)(song)到(dao)三輥(gun)軋(ya)(ya)(ya)(ya)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)機(ji)(ji)(ji)(ji)(ji)(ji)上(shang)進行軋(ya)(ya)(ya)(ya)制。連軋(ya)(ya)(ya)(ya)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)機(ji)(ji)(ji)(ji)(ji)(ji)為8機(ji)(ji)(ji)(ji)(ji)(ji)架,脫棒后的(de)(de)(de)(de)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)子(zi)經加熱送(song)(song)張(zhang)(zhang)力(li)(li)減徑(jing)(jing)機(ji)(ji)(ji)(ji)(ji)(ji)減徑(jing)(jing),張(zhang)(zhang)力(li)(li)減徑(jing)(jing)后的(de)(de)(de)(de)鋼(gang)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)經冷(leng)(leng)床冷(leng)(leng)卻,然(ran)后用(yong)多臺(tai)冷(leng)(leng)鋸(ju)(ju)鋸(ju)(ju)成(cheng)(cheng)定尺長度(du),并送(song)(song)去進行成(cheng)(cheng)品精整。

2. Lorain 不銹鋼管廠連軋管機組

近(jin)代連(lian)續軋管(guan)(guan)技術(shu)的發展是從1949年美國Lorain不銹鋼管(guan)(guan)廠連(lian)軋管(guan)(guan)機投產(chan)開始的,Lorain 廠的連(lian)管(guan)(guan)機組采用(yong)ф140mm規(gui)格的圓(yuan)管(guan)(guan)坯(pi)(pi)來生產(chan)ф51~102mm的水煤氣(qi)管(guan)(guan)、油管(guan)(guan)和鍋爐管(guan)(guan),生產(chan)能力為(wei)1.8萬V月。管(guan)(guan)坯(pi)(pi)經(jing)(jing)加(jia)熱、定(ding)心后去穿(chuan)(chuan)孔(kong)機,穿(chuan)(chuan)孔(kong)機由1臺3310kW,225r/min,13800V的同(tong)步電(dian)動(dong)機傳動(dong),減速(su)機的速(su)比為(wei)2.25,軋輥直徑為(wei)1070mm,輥身長610mm,喂(wei)入角固定(ding)為(wei)10°,軋輥線速(su)度約(yue)(yue)5.63m/s.ф146mm 穿(chuan)(chuan)孔(kong)坯(pi)(pi)出口速(su)度為(wei)0.915m/s.穿(chuan)(chuan)孔(kong)過程(cheng)完畢后,頂桿從穿(chuan)(chuan)孔(kong)坯(pi)(pi)中抽出,隨即穿(chuan)(chuan)孔(kong)坯(pi)(pi)被拔出,滾到定(ding)位輥道上,在這里(li)穿(chuan)(chuan)孔(kong)坯(pi)(pi)被移送(song)到與連(lian)軋管(guan)(guan)機入口端(duan)相距一(yi)定(ding)距離為(wei)止。此(ci)時,穿(chuan)(chuan)孔(kong)坯(pi)(pi)被拔到穿(chuan)(chuan)芯(xin)棒(bang)(bang)輥道上,在此(ci)1根約(yue)(yue)19.2m長的經(jing)(jing)過涂油的芯(xin)棒(bang)(bang)插(cha)入穿(chuan)(chuan)孔(kong)坯(pi)(pi),然后開始連(lian)軋過程(cheng),芯(xin)棒(bang)(bang)用(yong)低合金(jin)鋼制造,每(mei)根芯(xin)棒(bang)(bang)可用(yong)2000~2500次,然后重車后再用(yong)。

連續軋管(guan)機(ji)為(wei)9機(ji)架(jia),機(ji)架(jia)中心(xin)距為(wei)1120mm.每個(ge)機(ji)架(jia)裝(zhuang)有兩個(ge)直(zhi)徑為(wei)660mm、輥(gun)身長228mm的軋輥(gun),總(zong)容量(liang)為(wei)6250kW,由變流機(ji)組供電。

在(zai)連續軋管(guan)機上,穿(chuan)孔坯在(zai)芯棒上進行軋制;頭兩個機架對穿(chuan)孔坯減徑,使其內表面同芯棒相接觸,在(zai)第34機架中得(de)到較大(da)的減壁量;在(zai)第5、6機架中,管(guan)壁繼續減薄,但減壁量微小些;第7、8機架是輾光機架;而第9機架則(ze)將橢(tuo)圓形(xing)的毛管(guan)軋圓以便脫棒。

從連續軋管(guan)軋中軋出來以(yi)(yi)后(hou),帶芯(xin)(xin)棒(bang)的(de)(de)鋼(gang)管(guan)被(bei)橫移(yi)到脫棒(bang)機(ji)上。脫棒(bang)機(ji)的(de)(de)輥道(dao)是傳動的(de)(de),它可(ke)以(yi)(yi)將鋼(gang)管(guan)往回(hui)(hui)送,直到芯(xin)(xin)棒(bang)的(de)(de)尾(wei)端(duan)被(bei)脫棒(bang)機(ji)的(de)(de)卡爪卡住,將芯(xin)(xin)棒(bang)抽出來,抽出來的(de)(de)芯(xin)(xin)棒(bang)經(jing)輥道(dao)和臺架返回(hui)(hui)連軋管(guan)機(ji)前進行(xing)冷卻(que)、涂油以(yi)(yi)便再使(shi)用。鋼(gang)管(guan)經(jing)再加(jia)熱后(hou)送到12架定徑(jing)機(ji)或12架減徑(jing)機(ji),軋制成(cheng)熱軋成(cheng)品管(guan)。

美國不銹(xiu)鋼管廠家的(de)張力減(jian)(jian)徑(jing)(jing)機(ji)(ji)為二(er)輥(gun)式,12機(ji)(ji)架(jia)(jia),機(ji)(ji)架(jia)(jia)中心距(ju)為368mm,每個機(ji)(ji)架(jia)(jia)由1臺(tai)147kW,850~1700r/min的(de)直流(liu)電(dian)機(ji)(ji)傳動,軋輥(gun)直徑(jing)(jing)為355mm,輥(gun)身(shen)長度(du)(du)為178mm,軋輥(gun)材質為合金鑄鐵,下(xia)輥(gun)不可調(diao)。張力減(jian)(jian)徑(jing)(jing)機(ji)(ji)的(de)出口速度(du)(du)為3.7~7.4m/s,每架(jia)(jia)的(de)減(jian)(jian)徑(jing)(jing)量(liang)為10%~12%,減(jian)(jian)壁量(liang)可達20%.由于張減(jian)(jian)時可以(yi)控制壁厚,所以(yi)用一(yi)種(zhong)直徑(jing)(jing)的(de)管子就可以(yi)得到多(duo)種(zhong)尺寸(cun)的(de)成(cheng)品不銹(xiu)鋼管,減(jian)(jian)徑(jing)(jing)后鋼管外(wai)徑(jing)(jing)范圍為50.8~76.2mm,最大長度(du)(du)可達43.3m。