浙江至德鋼業有限公司不銹鋼管生產技術人員發現,在張力減徑機上生產不銹鋼(gang)厚(hou)壁管的主要限制是產品質量問題,當生產D/S值為3.5~5.0的不銹鋼厚壁管時,內孔變(六)方的現象比較嚴重,對張力減徑機成品管質量的威脅很大,但這可采用較小的減徑率和橢圓度較小的孔型來解決。

至德鋼(gang)業通過(guo)調節(jie)軋(ya)輥或(huo)傳(chuan)動(dong)電機的(de)(de)(de)(de)(de)(de)轉速而獲得的(de)(de)(de)(de)(de)(de)軸向張力(li)(li)不僅是控制(zhi)壁(bi)厚,而且是改(gai)善不銹鋼(gang)管質量的(de)(de)(de)(de)(de)(de)最(zui)佳手段。由(you)于張力(li)(li)值(zhi)(zhi)限制(zhi)了不銹鋼(gang)管內表(biao)面的(de)(de)(de)(de)(de)(de)自由(you)變(bian)(bian)形(xing)(xing)(xing)(xing)(xing),所(suo)以也(ye)就能(neng)防止內表(biao)面出現軋(ya)制(zhi)缺陷。張力(li)(li)減(jian)(jian)徑(jing)薄壁(bi)管時(shi)(shi)所(suo)采(cai)用(yong)的(de)(de)(de)(de)(de)(de)張力(li)(li)值(zhi)(zhi)應考慮周向壓應力(li)(li)過(guo)大(da)時(shi)(shi)所(suo)出現的(de)(de)(de)(de)(de)(de)徑(jing)向壓垮現象。此外,在張力(li)(li)減(jian)(jian)徑(jing)工藝過(guo)程中(zhong)通常在軋(ya)件(jian)截面內發生(sheng)不均勻變(bian)(bian)形(xing)(xing)(xing)(xing)(xing),從(cong)而導致鋼(gang)管內表(biao)面出現或(huo)多(duo)或(huo)少的(de)(de)(de)(de)(de)(de)內多(duo)邊(bian)形(xing)(xing)(xing)(xing)(xing)(圖(tu)11-2),但是,通過(guo)正確調節(jie)張力(li)(li)值(zhi)(zhi),在不均勻變(bian)(bian)形(xing)(xing)(xing)(xing)(xing)區實現有(you)效(xiao)的(de)(de)(de)(de)(de)(de)減(jian)(jian)徑(jing)量仍是有(you)可能(neng)的(de)(de)(de)(de)(de)(de)。這種(zhong)變(bian)(bian)形(xing)(xing)(xing)(xing)(xing)的(de)(de)(de)(de)(de)(de)不均勻性是由(you)于與幾何形(xing)(xing)(xing)(xing)(xing)狀有(you)關的(de)(de)(de)(de)(de)(de)一些(xie)因素,如(ru)減(jian)(jian)徑(jing)率(lv)、摩(mo)擦條件(jian)以及變(bian)(bian)形(xing)(xing)(xing)(xing)(xing)抗(kang)力(li)(li)等引(yin)起的(de)(de)(de)(de)(de)(de),由(you)于軋(ya)輥布置的(de)(de)(de)(de)(de)(de)交替性,一方(fang)面在軋(ya)槽(cao)底部和側邊(bian)開(kai)口部具有(you)不同的(de)(de)(de)(de)(de)(de)變(bian)(bian)形(xing)(xing)(xing)(xing)(xing)條件(jian),另一方(fang)面處于這兩點(dian)之(zhi)間(jian)的(de)(de)(de)(de)(de)(de)中(zhong)間(jian)部分(fen)的(de)(de)(de)(de)(de)(de)變(bian)(bian)形(xing)(xing)(xing)(xing)(xing)亦不同于這兩點(dian)的(de)(de)(de)(de)(de)(de)變(bian)(bian)形(xing)(xing)(xing)(xing)(xing)。因此,當生(sheng)產(chan)不銹鋼(gang)厚壁(bi)管(即S/D值(zhi)(zhi)較大(da))時(shi)(shi),內多(duo)邊(bian)形(xing)(xing)(xing)(xing)(xing)現象特別嚴重(zhong),不銹鋼(gang)管內表(biao)面形(xing)(xing)(xing)(xing)(xing)狀與圓(yuan)形(xing)(xing)(xing)(xing)(xing)的(de)(de)(de)(de)(de)(de)差異更明顯。

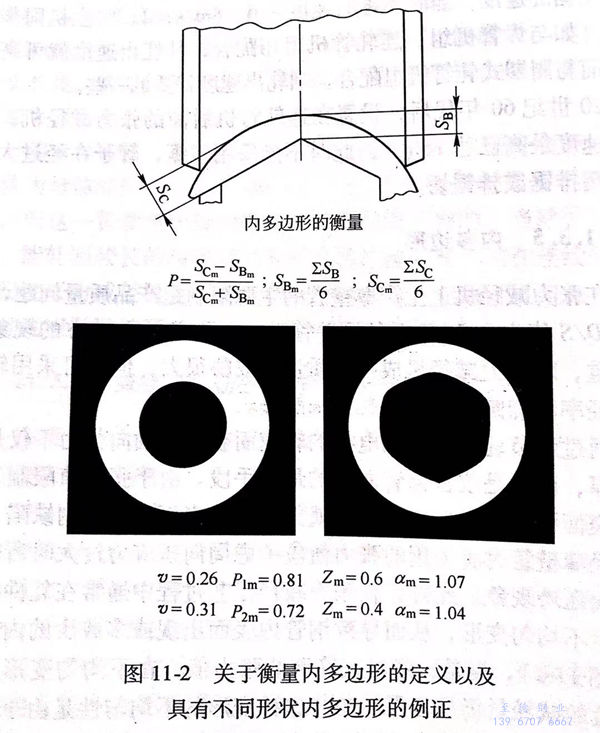

浙江至德(de)鋼業有(you)限公(gong)司技術人員將相對于軋(ya)輥(gun)布置(zhi)的(de)(de)內多邊形的(de)(de)劇烈程度(du)和位置(zhi)定義為P(圖11-2)。當(dang)孔型設計中(zhong)采用較大(da)(da)(da)的(de)(de)橢圓(yuan)度(du)即(ji)α值(zhi)時(shi)(shi),當(dang)以下(xia)各參數(shu)發生變化時(shi)(shi),如(ru)(1)不銹(xiu)鋼管直(zhi)徑較大(da)(da)(da)(假定D/S比(bi)為定值(zhi));(2)軋(ya)輥(gun)直(zhi)徑較小(xiao);(3)張力值(zhi)較大(da)(da)(da);(4)D/S比(bi)較小(xiao);(5)單架減徑率較大(da)(da)(da),則P值(zhi)增(zeng)(zeng)大(da)(da)(da)。此外,P值(zhi)的(de)(de)絕對值(zhi)隨著以下(xia)各參數(shu)的(de)(de)增(zeng)(zeng)大(da)(da)(da)而增(zeng)(zeng)大(da)(da)(da):(1)孔型的(de)(de)橢圓(yuan)增(zeng)(zeng)大(da)(da)(da)時(shi)(shi);(2)總減徑量增(zeng)(zeng)大(da)(da)(da)時(shi)(shi)。