冷彎成(cheng)型(xing)產品在生產加工(gong)時一定要(yao)注意(yi)產品的(de)彈性變形和在成(cheng)型(xing)過程中形成(cheng)的(de)張力,主要(yao)特點如下(xia):

1. 產(chan)品的彈性變形

冷(leng)彎產(chan)品(pin)質(zhi)量很大(da)程度(du)上取決于冷(leng)彎成(cheng)(cheng)(cheng)型(xing)機(ji)的(de)精(jing)度(du)。欲正確調(diao)整冷(leng)彎成(cheng)(cheng)(cheng)型(xing)機(ji),必須(xu)要(yao)預先(xian)確定(ding)金屬對輥的(de)壓力(li)與輥縫之間(jian)的(de)變(bian)(bian)化關系(xi),即彈(dan)性(xing)(xing)變(bian)(bian)形(xing)(xing)情況。成(cheng)(cheng)(cheng)型(xing)機(ji)的(de)彈(dan)性(xing)(xing)變(bian)(bian)形(xing)(xing)由(you)工作輥、軸承(cheng)及軸承(cheng)座、機(ji)架牌坊、壓下裝(zhuang)置等的(de)彈(dan)性(xing)(xing)變(bian)(bian)形(xing)(xing)和安裝(zhuang)間(jian)隙組成(cheng)(cheng)(cheng)。研究表明(ming),當總負載不大(da)時,軋輥彈(dan)性(xing)(xing)變(bian)(bian)形(xing)(xing)僅占總彈(dan)性(xing)(xing)變(bian)(bian)形(xing)(xing)的(de)25%;而當載荷大(da)時(達200kN),成(cheng)(cheng)(cheng)型(xing)輥彈(dan)性(xing)(xing)變(bian)(bian)形(xing)(xing)占總彈(dan)性(xing)(xing)變(bian)(bian)形(xing)(xing)的(de)70%。可見成(cheng)(cheng)(cheng)型(xing)輥的(de)彈(dan)性(xing)(xing)變(bian)(bian)形(xing)(xing)是(shi)成(cheng)(cheng)(cheng)型(xing)機(ji)彈(dan)性(xing)(xing)變(bian)(bian)形(xing)(xing)中的(de)主要(yao)部分(fen)。

生(sheng)產實(shi)際及理論計算表明,對于(yu)(1~4)mm×(400~1500)mm冷(leng)彎成型機,當冷(leng)彎集中載荷為200kN時(shi),成型輥彈性(xing)變形達1.49mm.

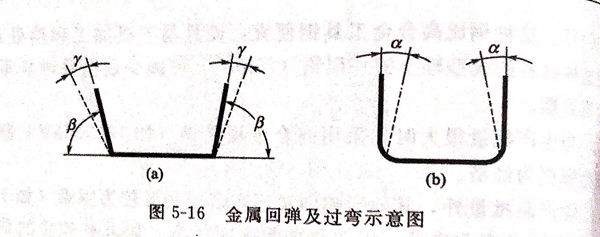

成(cheng)型(xing)機(ji)彈(dan)(dan)性變(bian)形(xing)對產(chan)(chan)品(pin)質量的影響可在成(cheng)型(xing)輥孔(kong)型(xing)設計中設置輥縫時加以(yi)補(bu)償。它應等于金(jin)屬料厚度(du)與彈(dan)(dan)跳(tiao)間距差值。另外(wai),冷彎(wan)生產(chan)(chan)實踐及(ji)理論(lun)研(yan)究(jiu)表明,冷彎(wan)過程(cheng)中除(chu)塑性變(bian)形(xing)外(wai),還存在彈(dan)(dan)性變(bian)形(xing)和彈(dan)(dan)塑性變(bian)形(xing)共存的狀況,當金(jin)屬移(yi)出孔(kong)型(xing)后,彎(wan)曲角(jiao)要發(fa)生變(bian)化。如圖5-16(a)所示,設計彎(wan)曲角(jiao)為β,移(yi)出孔(kong)型(xing)后會(hui)回(hui)彈(dan)(dan)γ角(jiao)度(du),因此(ci)欲得精確形(xing)狀產(chan)(chan)品(pin),成(cheng)品(pin)道次應考慮過量彎(wan)角(jiao)度(du),以(yi)彌補(bu)回(hui)彈(dan)(dan),見圖5-16(b).實踐證明,材料彈(dan)(dan)性極限越(yue)(yue)(yue)(yue)大(da),回(hui)彈(dan)(dan)就越(yue)(yue)(yue)(yue)大(da),材料越(yue)(yue)(yue)(yue)厚回(hui)彈(dan)(dan)越(yue)(yue)(yue)(yue)大(da),彎(wan)曲臂(bei)越(yue)(yue)(yue)(yue)長回(hui)彈(dan)(dan)越(yue)(yue)(yue)(yue)大(da),彎(wan)曲角(jiao)越(yue)(yue)(yue)(yue)多回(hui)彈(dan)(dan)也會(hui)越(yue)(yue)(yue)(yue)大(da)。

此外工藝過(guo)(guo)程的(de)不(bu)同(tong),材料彎(wan)(wan)曲(qu)時應(ying)力(li)、應(ying)變狀態不(bu)同(tong),回(hui)彈(dan)量亦不(bu)同(tong)。一(yi)般(ban)認為,對于簡單(dan)斷面冷彎(wan)(wan)型鋼,由于彎(wan)(wan)折(zhe)處及邊(bian)部存在(zai)拉應(ying)力(li),回(hui)彈(dan)較小,所以一(yi)般(ban)可不(bu)取(qu)過(guo)(guo)量彎(wan)(wan)角度,或者僅考(kao)慮30'~1°即(ji)可。而對于波紋型鋼,中心波要考(kao)慮向內過(guo)(guo)彎(wan)(wan)1°,邊(bian)波要大30'。

2. 機組張力

在(zai)冷彎成(cheng)(cheng)型(xing)機(ji)組上,帶鋼前進的(de)驅(qu)動力是(shi)通過驅(qu)動輥和帶鋼之間的(de)摩擦力傳遞的(de)。為了在(zai)成(cheng)(cheng)型(xing)過程中形(xing)成(cheng)(cheng)張(zhang)力、不產生堆鋼、使(shi)成(cheng)(cheng)型(xing)后型(xing)鋼平(ping)直,成(cheng)(cheng)型(xing)輥的(de)平(ping)均輥徑要加工成(cheng)(cheng)從第一(yi)(yi)(yi)架(jia)開始逐漸(jian)增(zeng)大(da)的(de)趨勢,即(ji)Dn+1稍大(da)于Dn,使(shi)后一(yi)(yi)(yi)架(jia)對前一(yi)(yi)(yi)架(jia)有一(yi)(yi)(yi)個拉伸作用。由于直徑增(zeng)加其(qi)線(xian)速度就會增(zeng)加,因此在(zai)架(jia)次之間就形(xing)成(cheng)(cheng)了張(zhang)力,從而帶鋼能平(ping)直地(di)運行(xing)。

Dn+1=(1.005~1.010)Dn

式中 Dn 第n架成(cheng)型輥(gun)平均直(zhi)徑;

Dn+1 第n+1架成型輥平均直徑。