落錘(chui)成(cheng)型用(yong)(yong)(yong)的(de)沖(chong)(chong)頭(tou)一般都是(shi)(shi)(shi)用(yong)(yong)(yong)鉛來(lai)制造(zao)的(de),這(zhe)是(shi)(shi)(shi)因為鉛沖(chong)(chong)頭(tou)可(ke)以(yi)在沖(chong)(chong)模(mo)(mo)(mo)上直(zhi)接鑄(zhu)成(cheng);另一方面,其重(zhong)量(liang)還(huan)有助于在落錘(chui)成(cheng)型時增(zeng)加(jia)沖(chong)(chong)擊(ji)能量(liang)。雖然鉛是(shi)(shi)(shi)可(ke)以(yi)重(zhong)復(fu)使用(yong)(yong)(yong)的(de),但是(shi)(shi)(shi)對于每個鑄(zhu)造(zao)沖(chong)(chong)頭(tou)來(lai)說,它所能加(jia)工成(cheng)型的(de)工件(jian)數量(liang)還(huan)是(shi)(shi)(shi)比較(jiao)少的(de)(約(yue)200件(jian))。采用(yong)(yong)(yong)塑料落錘(chui)沖(chong)(chong)頭(tou)和沖(chong)(chong)模(mo)(mo)(mo)成(cheng)型的(de)工件(jian)表面光潔度(du)較(jiao)高,這(zhe)是(shi)(shi)(shi)其他方法不能相(xiang)比的(de)。鋼制落錘(chui)沖(chong)(chong)模(mo)(mo)(mo)則用(yong)(yong)(yong)于大批量(liang)生(sheng)產以(yi)及(ji)壓印和整形加(jia)工中(zhong)。

落(luo)錘(chui)沖(chong)模的設(she)計(ji)通常和沖(chong)壓(ya)(ya)成(cheng)型(xing)(xing)相(xiang)似(si),同樣需要在沖(chong)頭和沖(chong)模上實(shi)施倒圓,以降低被加(jia)工成(cheng)型(xing)(xing)金屬上的集中(zhong)應力。在沖(chong)模設(she)計(ji)中(zhong),關于卷邊成(cheng)型(xing)(xing)以及作為落(luo)錘(chui)成(cheng)型(xing)(xing)中(zhong)使(shi)金屬順利流動的方(fang)法均(jun)與普通沖(chong)壓(ya)(ya)成(cheng)型(xing)(xing)相(xiang)似(si)。

1. 產品質量

采用落(luo)錘成型方(fang)法(fa)所(suo)生(sheng)產(chan)的(de)(de)(de)工(gong)件尺寸(cun)的(de)(de)(de)一致性,均要(yao)(yao)比其他方(fang)法(fa)生(sheng)產(chan)的(de)(de)(de)差一些。這是(shi)因為(wei)工(gong)件所(suo)承(cheng)受的(de)(de)(de)沖(chong)擊程度(du)(du)要(yao)(yao)取決于(yu)(yu)操作人員的(de)(de)(de)熟練程度(du)(du),以及沖(chong)頭在局部(bu)大(da)負(fu)荷下(xia)與(yu)工(gong)件產(chan)生(sheng)相對(dui)移位的(de)(de)(de)緣故。然(ran)而,在落(luo)錘成型中,所(suo)產(chan)生(sheng)的(de)(de)(de)彈性回彈(后效)要(yao)(yao)比其他方(fang)法(fa)較小。其原因是(shi)由于(yu)(yu)此時工(gong)件所(suo)承(cheng)受的(de)(de)(de)沖(chong)擊力很大(da),而且(qie)變形速度(du)(du)也很快。

2. 潤(run)滑

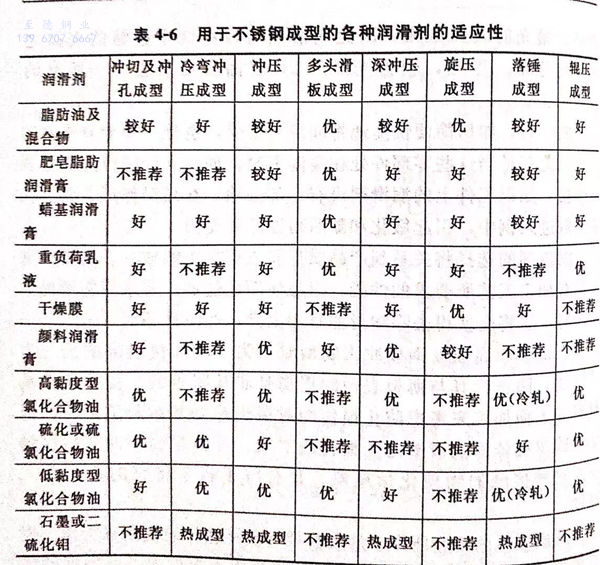

落錘成型所使(shi)(shi)用(yong)的潤(run)滑(hua)劑(ji),見表4-6。如果(guo)加(jia)工(gong)變(bian)(bian)形非常(chang)劇烈,需要在(zai)工(gong)件(jian)的兩個加(jia)工(gong)階段(duan)之間(jian)進行中間(jian)退火時(shi),則必(bi)須將(jiang)潤(run)滑(hua)劑(ji)(因為潤(run)滑(hua)劑(ji)中含有石墨或(huo)硫等雜質(zhi))以及模具(ju)上(shang)的鉛或(huo)鋅從加(jia)工(gong)件(jian)表面(mian)上(shang)徹底清除。如果(guo)這些雜質(zhi)殘留(liu)在(zai)不銹(xiu)鋼工(gong)件(jian)表面(mian)上(shang),在(zai)工(gong)件(jian)加(jia)熱(re)時(shi)雜質(zhi)將(jiang)會導致工(gong)件(jian)表面(mian)變(bian)(bian)壞并影響其使(shi)(shi)用(yong)性(xing)能。

3. 與沖壓成型的比較

雖(sui)然沖壓成型(xing)可(ke)(ke)以迅速(su)(su)完成,但它是(shi)一(yi)種沖頭速(su)(su)度和夾緊壓力可(ke)(ke)以精確(que)控制的成型(xing)方法。相反,在(zai)(zai)(zai)(zai)落(luo)錘成型(xing)過(guo)程中(zhong)只能是(shi)通過(guo)突(tu)然沖擊這一(yi)途徑使工(gong)件成型(xing)。在(zai)(zai)(zai)(zai)某些(xie)應用(yong)實例(li)中(zhong),利用(yong)落(luo)錘高速(su)(su)釋放(fang)能量的方法可(ke)(ke)以克(ke)服工(gong)件在(zai)(zai)(zai)(zai)加工(gong)中(zhong)的變(bian)形難度。在(zai)(zai)(zai)(zai)其他情況下,特別是(shi)那些(xie)要求(qiu)坯料(liao)夾緊壓力較(jiao)嚴格的場合,采(cai)用(yong)沖壓成型(xing)方法可(ke)(ke)以生產出(chu)優質而價廉(lian)的零(ling)件,但此時應使用(yong)特制的模具。

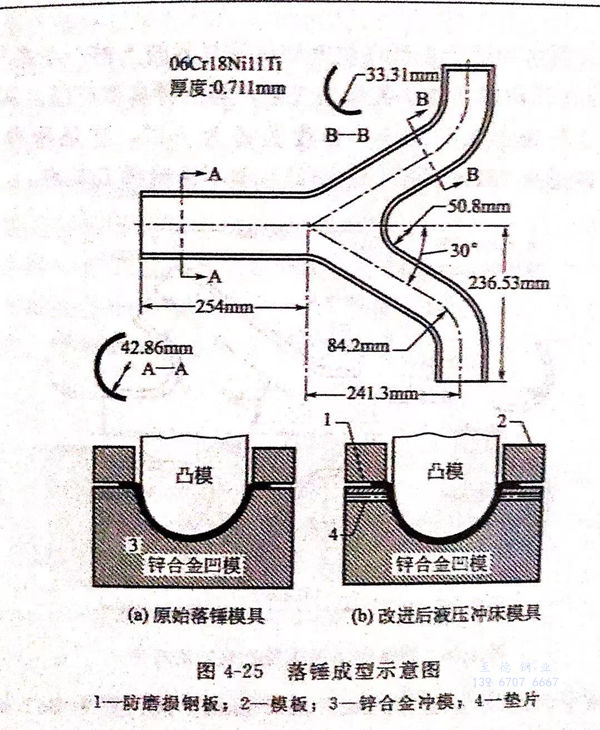

圖(tu)4-25所示(shi)的是(shi)用落錘成(cheng)型(xing)方(fang)法加工成(cheng)型(xing)排氣管(guan)(guan)的示(shi)意圖(tu),成(cheng)型(xing)所用的工具裝置(zhi)如圖(tu)4-25左下方(fang)所示(shi)。但是(shi),由(you)于(yu)排氣管(guan)(guan)呈30°交叉(cha),所以在交叉(cha)處易(yi)產生(sheng)皺折,并且(qie)生(sheng)產一個工件需(xu)要(yao)六道工序(xu),總時間為(wei)2min,因此這(zhe)種(zhong)成(cheng)型(xing)方(fang)法是(shi)不夠理想的。

經(jing)過重(zhong)新(xin)(xin)設(she)計后用(yong)于一(yi)臺500t液(ye)壓(ya)式沖(chong)(chong)壓(ya)機的(de)(de)(de)工具(ju),如圖4-25右下方所示(shi)。用(yong)于落(luo)錘(chui)成型(xing)的(de)(de)(de)鋅合金(jin)沖(chong)(chong)模可以(yi)重(zhong)新(xin)(xin)使用(yong)在(zai)沖(chong)(chong)壓(ya)機上,但是為了經(jing)受不銹鋼沖(chong)(chong)壓(ya)成型(xing)時的(de)(de)(de)磨(mo)損(sun)(sun),應將沖(chong)(chong)模削平并且安裝有防磨(mo)損(sun)(sun)的(de)(de)(de)低碳鋼護板(ban)(ban)。采用(yong)半徑(jing)為42.863mm的(de)(de)(de)落(luo)錘(chui)進行成型(xing)是非常適宜的(de)(de)(de),此時的(de)(de)(de)彈(dan)(dan)性回彈(dan)(dan)將變得(de)很小。但是,在(zai)沖(chong)(chong)壓(ya)機上的(de)(de)(de)防止彈(dan)(dan)性回彈(dan)(dan)的(de)(de)(de)沖(chong)(chong)模,在(zai)尺寸上必須加深,這可以(yi)采用(yong)在(zai)沖(chong)(chong)和防磨(mo)損(sun)(sun)板(ban)(ban)之間加墊片的(de)(de)(de)方法來實(shi)現。

用沖壓(ya)成(cheng)型方法(fa)加工的工件可(ke)以完全(quan)消(xiao)除(chu)皺折,其生產率(lv)為(wei)分(fen)鐘兩(liang)個(ge)工件。它與落錘(chui)方法(fa)比(bi)較,每生產一個(ge)工件可(ke)節(jie)約1.5min.

這兩(liang)種方法所用(yong)(yong)的(de)坯(pi)料均為(wei)退火后(hou)的(de)06Cr18Ni11Ti(321)型不銹(xiu)鋼(gang),其厚度(du)為(wei)0.711mm,面積為(wei)580mmx609.6mm.落錘成(cheng)型可(ke)不采用(yong)(yong)潤滑劑,沖壓成(cheng)型則需(xu)使(shi)用(yong)(yong)蠟乳化液。成(cheng)型后(hou)的(de)修(xiu)切(qie)是在(zai)第二臺沖壓機上完成(cheng)的(de)。

將落(luo)錘(chui)成(cheng)(cheng)型(xing)(xing)(xing)和沖(chong)壓(ya)成(cheng)(cheng)型(xing)(xing)(xing)進行對比,結果是(shi)落(luo)錘(chui)成(cheng)(cheng)型(xing)(xing)(xing)存在有皺折消(xiao)除(chu)和成(cheng)(cheng)本降低的(de)問題。

一般來(lai)說,落(luo)錘(chui)成型(xing)(xing)常用于試(shi)生(sheng)(sheng)產(chan)(chan),經過落(luo)錘(chui)試(shi)成型(xing)(xing)合格后,再(zai)使用改進(jin)后的(de)沖(chong)模,采(cai)用沖(chong)壓(ya)機進(jin)行沖(chong)壓(ya)成型(xing)(xing)的(de)大批(pi)(pi)量(liang)生(sheng)(sheng)產(chan)(chan)。如果改進(jin)型(xing)(xing)沖(chong)模的(de)質量(liang)和成型(xing)(xing)效果很好(hao),可以用于小批(pi)(pi)量(liang)落(luo)錘(chui)成型(xing)(xing)生(sheng)(sheng)產(chan)(chan)。

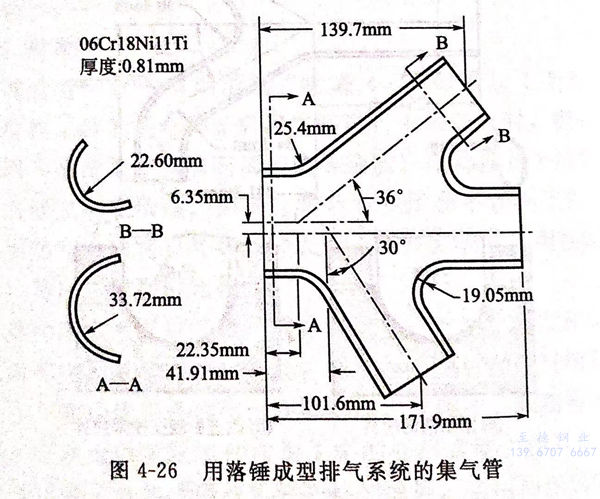

圖4-26所(suo)示為用(yong)于(yu)小型飛機發動機排氣(qi)系統上(shang)的(de)(de)一個集(ji)氣(qi)管。這種(zhong)零件是(shi)用(yong)落錘成(cheng)型的(de)(de)小批量(liang)加工(gong)生產的(de)(de)一種(zhong)典型產品。其零件整個尺寸公(gong)差(cha)(cha)為±0.813mm,角(jiao)度公(gong)差(cha)(cha)為±2°,它(ta)是(shi)用(yong)厚度為0.813mm的(de)(de)退火06Cr18Ni11Ti(321)型不(bu)銹鋼加工(gong)成(cheng)的(de)(de)。

落錘(chui)平臺的尺(chi)寸(cun)為762mm×609.6mm,其行(xing)程為863.6mm.沖頭是用(yong)(yong)鉛制造的,而沖模(mo)則采(cai)用(yong)(yong)鋅(xin)合金制造。毛坯料(liao)尺(chi)寸(cun)為304.8mm×228.6mm.模(mo)具的安裝時(shi)間(jian)需要(yao)1.15h,其中包括落錘(chui)的清理時(shi)間(jian)。為了加工(gong)成(cheng)型(xing)工(gong)件(jian),落錘(chui)需要(yao)進行(xing)5次沖擊。在落錘(chui)成(cheng)型(xing)中橡皮是起坯料(liao)夾具的作用(yong)(yong),以便將壓(ya)力分布在整(zheng)個工(gong)件(jian)上(shang)。橡皮厚度在開始的4次沖擊中每(mei)次都在減薄,以便在最(zui)后一次擊中以沖模(mo)為底。然后,工(gong)件(jian)在沖床上(shang)用(yong)(yong)沖頭進行(xing)修切。