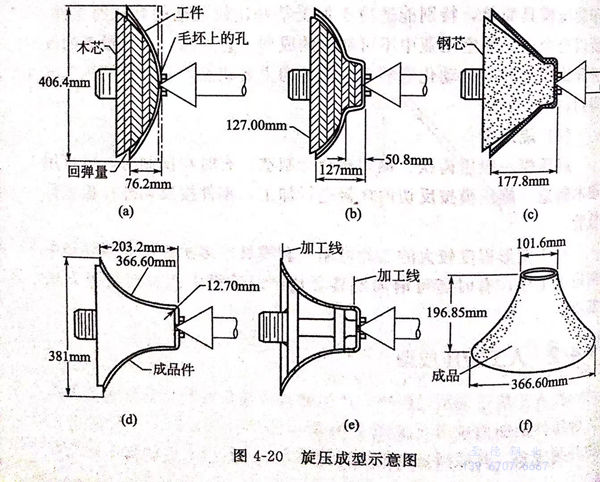

在人工(gong)旋(xuan)(xuan)壓成(cheng)型(xing)過程中,產(chan)生的減(jian)薄量與(yu)成(cheng)型(xing)變形(xing)量有關。人工(gong)旋(xuan)(xuan)壓件(jian)的斷面減(jian)薄至(zhi)如圖(tu)4-20所示的那種(zhong)程度(du)時,工(gong)件(jian)常(chang)會產(chan)生開(kai)裂現象(xiang)。其原因(yin)是由于(yu)加(jia)工(gong)量過大,而且中心(xin)區的加(jia)工(gong)硬(ying)化(hua)程度(du)超過材料的承受能力,因(yin)而導致工(gong)件(jian)開(kai)裂。如果(guo)在旋(xuan)(xuan)壓成(cheng)型(xing)之前,工(gong)件(jian)在沖壓機上沖壓成(cheng)類似(si)半球形(xing)杯體(ti)再旋(xuan)(xuan)壓出變化(hua)劇烈的喇叭形(xing)寬邊(見圖(tu)4-20),旋(xuan)(xuan)壓會容(rong)易一些。

下面介紹10Cr18Ni12(305)型不銹鋼的旋壓成型。

材質為(wei)10Cr18Ni12(305)型(xing)(xing)不銹鋼(gang)(gang)(gang)的(de)錐(zhui)形(xing)(xing)體(ti)的(de)4次人工旋(xuan)(xuan)壓成(cheng)型(xing)(xing),如圖4-20所示。直徑(jing)為(wei)366.6mm的(de)錐(zhui)形(xing)(xing)體(ti)是經(jing)一道(dao)預沖壓成(cheng)型(xing)(xing)和4道(dao)人工旋(xuan)(xuan)壓成(cheng)型(xing)(xing)而完成(cheng)的(de)。該工件所使用的(de)坯料(liao)厚度(du)為(wei)0.940mm、直徑(jing)為(wei)406.4mm的(de)10Cr18Ni12(305)型(xing)(xing)不銹鋼(gang)(gang)(gang),這種不銹鋼(gang)(gang)(gang)坯料(liao)可具(ju)有2D(薄板(ban))表(biao)面或1號(帶鋼(gang)(gang)(gang))表(biao)面光(guang)潔度(du)。該工件也可用其(qi)他型(xing)(xing)號的(de)奧(ao)氏體(ti)不銹鋼(gang)(gang)(gang)來生(sheng)產,但是其(qi)每道(dao)工序的(de)變形(xing)(xing)量隨(sui)著加工硬化程度(du)的(de)提高而降低(di)。

如圖4-20所(suo)(suo)示(shi),旋壓(ya)(ya)成(cheng)型(xing)所(suo)(suo)用的型(xing)芯是用木材或鋼做成(cheng)的,旋壓(ya)(ya)成(cheng)型(xing)輥則是用淬火鋼材制成(cheng)的。在(zai)(zai)第一(yi)次旋壓(ya)(ya)成(cheng)型(xing)時(shi),壓(ya)(ya)力作用在(zai)(zai)整個坯(pi)料上。在(zai)(zai)其他三(san)次加(jia)(jia)(jia)工(gong)(gong)中,壞料邊緣不進行旋壓(ya)(ya),這就(jiu)會引起毛坯(pi)邊部增(zeng)厚至1.778mm,同(tong)時(shi)希(xi)望所(suo)(suo)得到(dao)的工(gong)(gong)件外形(xing)(xing)錐形(xing)(xing)體中部的減薄(bo)(bo)量最大(da),可使壁(bi)厚尺寸(cun)達到(dao)0.686mm(變(bian)形(xing)(xing)率(lv)為28%).與此同(tong)時(shi),工(gong)(gong)件表面(mian)積將比原來增(zeng)加(jia)(jia)(jia)40%.由于工(gong)(gong)件減薄(bo)(bo)和(he)面(mian)積增(zeng)加(jia)(jia)(jia),這些急劇的變(bian)化會給加(jia)(jia)(jia)工(gong)(gong)變(bian)形(xing)(xing)帶來極大(da)影響,因此工(gong)(gong)件在(zai)(zai)加(jia)(jia)(jia)工(gong)(gong)過程中,必須進行兩次退火加(jia)(jia)(jia)工(gong)(gong)工(gong)(gong)序。

操作程(cheng)序如下:

①. 首(shou)先在坯(pi)料(尺(chi)寸為:厚度0.94mm;直徑408.4mm)中(zhong)心部位,開一個(ge)直徑為6.35mm的(de)中(zhong)心孔,并預沖壓(ya)成型;

②. 采用(yong)人工的方法,通過(guo)成型輥對旋轉的芯棒施加(jia)壓力,使(shi)坯料凹深(shen)達(da)到76.2mm,旋壓加(jia)工速度為300r/min;

③. 用(yong)第二個層狀硬木型芯將坯(pi)料凹深處旋壓至127mm,邊部(bu)深度在(zai)50.8mm以內(nei);

④. 在(zai)1038℃的氫氣氛中進行中間(jian)退(tui)火,然后空冷,用鋼型芯(xin)將坯料凹深(shen)旋(xuan)壓至177.8mm邊部,深(shen)度(du)在(zai)25.4mm以內;

⑤. 在與工序(xu)③相同的條件下退火,用鋼型芯(xin)將(jiang)坯料凹深(shen)旋壓(ya)至(zhi)203.2mm,并最后加工成(cheng)型;

⑥. 在車床上對工件的(de)頂部和(he)底(di)部進行加(jia)工,使(shi)喇叭(ba)口(kou)的(de)高(gao)度(du)達到196.86mm;

⑦. 成品,上(shang)口直徑(jing)101.6mm,下口直徑(jing) 366.60mm,高196.85mm.

由于400系列不(bu)銹鋼的(de)延伸性能(neng)較差,所以(yi)不(bu)適宜用人工(gong)旋壓的(de)方法(fa)成型(xing),特別(bie)是當變形劇烈時更是如此(ci)。另外(wai)還要注意,對成型(xing)模具施(shi)加(jia)過大壓力,會引起加(jia)工(gong)表面(mian)的(de)磨(mo)損,從而導致工(gong)件過早地減薄和開裂。

由(you)于(yu)工具對金(jin)屬的(de)(de)作用,急劇旋壓(ya)成型件的(de)(de)表面往往比較粗(cu)糙。這樣,用400系列不銹鋼旋壓(ya)加工成型后的(de)(de)工件,拋(pao)光(guang)和高精度(du)研磨(mo)的(de)(de)成本就顯(xian)得非常高。因此,在研磨(mo)和拋(pao)光(guang)之前,須對凹凸不平的(de)(de)工件先進行粗(cu)磨(mo),使其表面變得平滑(hua)一些。

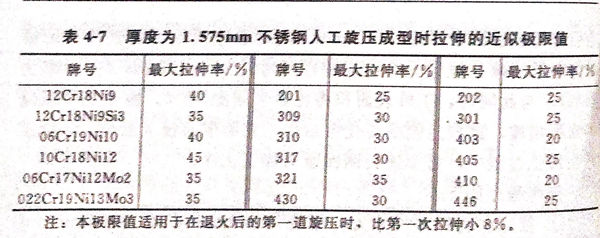

表(biao)4-7給出了人工旋壓時拉伸的(de)近似(si)極(ji)限。該表(biao)適用于(yu)厚度為1.575mm的(de)完全退火材(cai)料。退火后的(de)二次拉伸量比第(di)一次小(xiao)8%。零件各部分的(de)拉伸量并不需要完全一致(zhi),它是根據成型變(bian)形量的(de)不同而有變(bian)化的(de)。

所(suo)有(you)300系(xi)列的(de)不銹(xiu)鋼均可(ke)采用旋(xuan)(xuan)壓(ya)成型(xing)方法,但(dan)是加工硬化較低的(de) 12Cr18Ni9(302)、06Cr19Ni10(304)和 10Cr18Ni12(305)型(xing)鋼在中間退火前的(de)旋(xuan)(xuan)壓(ya)加工量(liang)(liang)比其(qi)(qi)他(ta)不銹(xiu)鋼大(da)。退火后的(de)工件(jian)必須經酸洗清除氧(yang)化鐵(tie)皮,以恢復其(qi)(qi)光潔的(de)表面。1號(帶鋼)或2D(薄拉)表面光潔度最適于大(da)變形旋(xuan)(xuan)壓(ya)工藝,因(yin)為(wei)此時金屬處于最軟和無應力狀態,其(qi)(qi)加工量(liang)(liang)可(ke)達(da)到最大(da)程度。

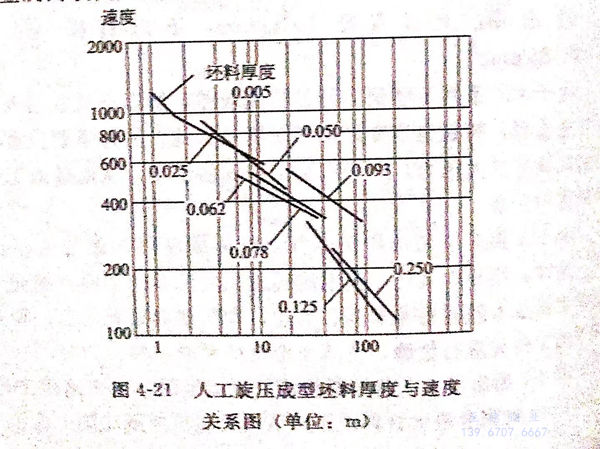

人工(gong)旋壓成(cheng)(cheng)型(xing)時,一般采用較(jiao)低的加工(gong)速度,圖(tu)4-21顯示出加工(gong)速度和厚度之(zhi)間的關(guan)系(xi)。因(yin)此,在(zai)成(cheng)(cheng)型(xing)工(gong)具的作用下(xia),將會引起成(cheng)(cheng)型(xing)金屬的表(biao)面(mian)嚴重磨(mo)損,同時也會產生較(jiao)大加工(gong)硬(ying)化。

雖然0.127mm的(de)(de)薄料(liao)到6.35mm的(de)(de)厚(hou)料(liao)都可以采用人(ren)工旋(xuan)壓方(fang)法成型(xing),但(dan)是一般情(qing)況下,人(ren)工旋(xuan)壓成型(xing)時不銹鋼原料(liao)的(de)(de)厚(hou)度(du)在0.305~3.175mm之間。此時角部倒圓至少應為被加工金屬厚(hou)度(du)的(de)(de)5倍。由于彈(dan)性回彈(dan)和熱(re)脹冷縮(suo)的(de)(de)影(ying)響(xiang),芯模尺寸和要求(qiu)的(de)(de)形狀尺寸必須預(yu)留(liu)一定的(de)(de)加工余量。