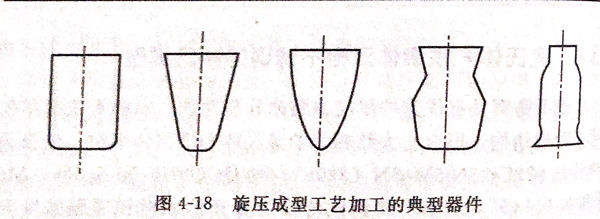

旋(xuan)(xuan)壓(ya)成(cheng)型是一種(zhong)歷(li)史悠久(jiu)的(de)工藝方法(fa),我(wo)國古時在10世紀就有(you)了這種(zhong)成(cheng)型方法(fa),后(hou)來(lai)于(yu)14世紀才傳(chuan)入歐洲。用旋(xuan)(xuan)壓(ya)成(cheng)型方法(fa)可制造各(ge)種(zhong)不同形狀的(de)旋(xuan)(xuan)轉(zhuan)面工件,如發動機罩、螺旋(xuan)(xuan)槳槳帽等。圖4-18是采(cai)用旋(xuan)(xuan)壓(ya)成(cheng)型工藝加工的(de)典型器件的(de)示意圖。

1. 旋壓成型原理

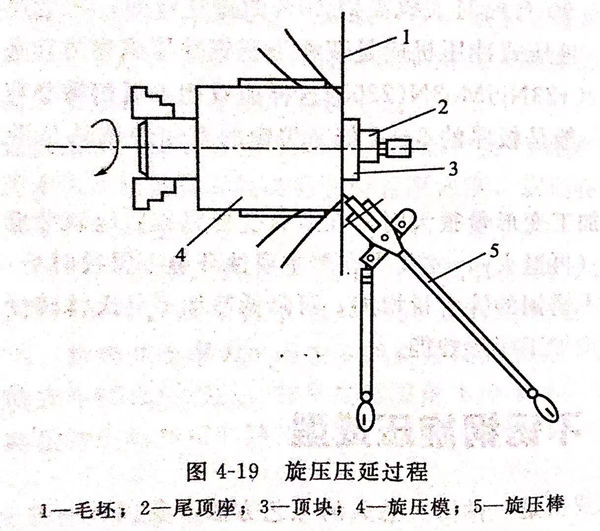

旋(xuan)(xuan)(xuan)壓(ya)成型用(yong)的(de)設備類似于車(che)床或由車(che)床改裝而成的(de),但最新發展有數控(kong)旋(xuan)(xuan)(xuan)壓(ya)床。旋(xuan)(xuan)(xuan)壓(ya)床的(de)工作(zuo)原(yuan)理(li)如圖4-19所示。用(yong)機床尾頂(ding)座(zuo)2通過頂(ding)塊3將(jiang)平(ping)板(ban)毛(mao)坯1壓(ya)緊于旋(xuan)(xuan)(xuan)壓(ya)模(mo)4上,毛(mao)坯連(lian)同模(mo)具一起旋(xuan)(xuan)(xuan)轉,操作(zuo)者用(yong)手操作(zuo)旋(xuan)(xuan)(xuan)壓(ya)棒,將(jiang)毛(mao)坯順次壓(ya)向(xiang)旋(xuan)(xuan)(xuan)壓(ya)模(mo),這時毛(mao)坯發生周向(xiang)收縮和徑向(xiang)延伸變形,最后旋(xuan)(xuan)(xuan)壓(ya)成型為要求的(de)形狀。

2. 旋壓注意(yi)事項

旋(xuan)壓(ya)成(cheng)(cheng)型過程的(de)(de)(de)(de)主(zhu)要問題是(shi)(shi)起皺(zhou)和局部變(bian)(bian)(bian)(bian)薄以(yi)(yi)及拉(la)裂。如(ru)圖4-19所示(shi)的(de)(de)(de)(de)旋(xuan)壓(ya)壓(ya)延過程,凸(tu)緣周邊起皺(zhou)決(jue)定(ding)于收縮變(bian)(bian)(bian)(bian)形(xing)(xing)程度(du)(即工(gong)(gong)件直徑和毛(mao)(mao)坯(pi)直徑之(zhi)比值(zhi))、毛(mao)(mao)坯(pi)的(de)(de)(de)(de)穩定(ding)性(xing)(如(ru)l./D.數值(zhi))、毛(mao)(mao)料(liao)(liao)(liao)轉(zhuan)速(su)以(yi)(yi)及操作(zuo)(zuo)者的(de)(de)(de)(de)經驗。提高毛(mao)(mao)坯(pi)的(de)(de)(de)(de)轉(zhuan)速(su)會(hui)增(zeng)加毛(mao)(mao)坯(pi)凸(tu)緣的(de)(de)(de)(de)穩定(ding)性(xing),但由手工(gong)(gong)操作(zuo)(zuo)不(bu)能保證均勻的(de)(de)(de)(de)縱(zong)向送進(jin),會(hui)造成(cheng)(cheng)局部過度(du)輾薄,一(yi)般成(cheng)(cheng)型加工(gong)(gong)所用的(de)(de)(de)(de)轉(zhuan)速(su)多在(zai)200~600r/min的(de)(de)(de)(de)范圍內。為(wei)了防止起皺(zhou)和旋(xuan)壓(ya)模(mo)(mo)圓(yuan)角(jiao)處(chu)材(cai)料(liao)(liao)(liao)變(bian)(bian)(bian)(bian)薄或拉(la)裂,操作(zuo)(zuo)順序(xu)應按如(ru)下進(jin)行(xing):首(shou)次操作(zuo)(zuo)時將(jiang)凸(tu)模(mo)(mo)圓(yuan)角(jiao)處(chu)材(cai)料(liao)(liao)(liao)趕(gan)(gan)形(xing)(xing)貼模(mo)(mo)形(xing)(xing)成(cheng)(cheng)帽形(xing)(xing)件;第(di)(di)二步(bu)操作(zuo)(zuo)時將(jiang)帽形(xing)(xing)件凸(tu)緣趕(gan)(gan)形(xing)(xing)成(cheng)(cheng)圓(yuan)錐面以(yi)(yi)增(zeng)加這(zhe)部分(fen)材(cai)料(liao)(liao)(liao)的(de)(de)(de)(de)剛度(du);第(di)(di)三步(bu)操作(zuo)(zuo)(防起皺(zhou))是(shi)(shi)旋(xuan)壓(ya)棒從毛(mao)(mao)料(liao)(liao)(liao)周邊向凸(tu)模(mo)(mo)圓(yuan)角(jiao)處(chu)趕(gan)(gan)并(bing)使毛(mao)(mao)料(liao)(liao)(liao)向凸(tu)模(mo)(mo)靠攏。以(yi)(yi)后的(de)(de)(de)(de)操作(zuo)(zuo)是(shi)(shi)重(zhong)復(fu)上述第(di)(di)二、三步(bu)驟。逐(zhu)步(bu)地將(jiang)材(cai)料(liao)(liao)(liao)旋(xuan)壓(ya)至貼模(mo)(mo)為(wei)止,最后再加以(yi)(yi)修整趕(gan)(gan)形(xing)(xing)和工(gong)(gong)件切邊。因(yin)為(wei)旋(xuan)壓(ya)過程的(de)(de)(de)(de)變(bian)(bian)(bian)(bian)形(xing)(xing)情況極(ji)其復(fu)雜(za),多半又是(shi)(shi)手工(gong)(gong)操作(zuo)(zuo),故成(cheng)(cheng)型之(zhi)成(cheng)(cheng)敗與操作(zuo)(zuo)者的(de)(de)(de)(de)經驗有直接(jie)的(de)(de)(de)(de)關系。

旋壓還可用于對工件進行縮(suo)口(kou)、卷邊、擴口(kou)等項成型加工作業。

3. 旋壓的優缺(que)點

旋壓(ya)(ya)的(de)缺(que)(que)點(dian)是(shi)零(ling)件變薄量(liang)較大,勞動強(qiang)度(du)較大,對操作(zuo)技術水平要(yao)求較高,而勞動生產(chan)率低等。旋壓(ya)(ya)工(gong)作(zuo)雖(sui)有這些缺(que)(que)點(dian),但是(shi)由于旋壓(ya)(ya)模具簡單,特(te)別能適應于加工(gong)某些比較復雜(za)的(de)旋轉面(mian)零(ling)件,所(suo)以至(zhi)今還是(shi)航(hang)空工(gong)業中不(bu)可缺(que)(que)少的(de)成型(xing)工(gong)藝方法(fa)。旋壓(ya)(ya)設備的(de)改(gai)進和旋壓(ya)(ya)過程的(de)自動化能夠克服上(shang)述的(de)主要(yao)缺(que)(que)點(dian),并且(qie)使旋壓(ya)(ya)工(gong)藝得到新(xin)的(de)發展(zhan)。

4. 旋壓模

旋壓模一般(ban)用(yong)鑄鐵、鋼和銅合(he)金制(zhi)造。有時在試制(zhi)時,也可用(yong)硬木(mu)制(zhi)造。旋壓模按(an)反切(qie)內樣板進行(xing)加工(gong),零件按(an)反切(qie)外樣板進行(xing)檢驗。

對于變形(xing)程度(du)較(jiao)大的工(gong)件可用一套模(mo)具經多次旋壓成型并經中間(jian)退火工(gong)序,有(you)時(shi)還可增(zeng)加模(mo)具套數,即采(cai)用中間(jian)過渡模(mo)等(deng)方(fang)法(fa)解決。