1. 堿(jian)性銅電刷鍍液的性質

堿性(xing)(xing)銅電刷鍍液(ye)呈微堿性(xing)(xing),pH為(wei)7~8,顯藍紫(zi)色。銅離子含(han)量(liang)均為(wei)50g/L,20℃時(shi)相(xiang)對密(mi)度為(wei)1.13,電導(dao)率為(wei)0.142 Ω-1·cm-1。工(gong)作(zuo)通風(feng)要(yao)好,不要(yao)用手接觸鍍液(ye)。

2. 堿性銅電(dian)刷鍍新的性質(zhi)及用途

堿(jian)性銅電(dian)刷鍍銅層結晶致密,結合力(li)好多用作過渡層或中間層、釬焊層和導電(dian)層,防(fang)滲碳和防(fang)氮化層。

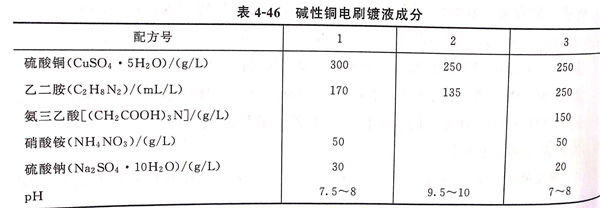

3. 堿性銅電(dian)刷鍍(du)液成分,見表4-46.

4. 堿(jian)性銅電刷鍍(du)液的配制

以配方3為例(li),在1000mL燒杯(bei)中(zhong)加(jia)(jia)(jia)入(ru)(ru)硫酸(suan)(suan)銅250g,蒸餾水250mL,加(jia)(jia)(jia)熱(re)攪拌(ban)(ban)溶(rong)(rong)解(jie),冷(leng)卻至20℃,量(liang)(liang)(liang)取二乙(yi)胺250mL,在攪拌(ban)(ban)下緩慢滴(di)入(ru)(ru)硫酸(suan)(suan)銅溶(rong)(rong)液(ye),由(you)于是放熱(re)反應,溫度升高后(hou)要冷(leng)卻后(hou)再加(jia)(jia)(jia)。在500mL的燒杯(bei)中(zhong),加(jia)(jia)(jia)入(ru)(ru)氨(an)三乙(yi)酸(suan)(suan)150g,加(jia)(jia)(jia)蒸餾水100mL,加(jia)(jia)(jia)入(ru)(ru)氫(qing)氧化(hua)鈉92g,攪拌(ban)(ban)使兩者溶(rong)(rong)解(jie),冷(leng)卻后(hou)加(jia)(jia)(jia)入(ru)(ru)硝酸(suan)(suan)銨50g,硫酸(suan)(suan)鈉20g,攪拌(ban)(ban)溶(rong)(rong)解(jie)后(hou)加(jia)(jia)(jia)入(ru)(ru)硫酸(suan)(suan)銅乙(yi)二胺溶(rong)(rong)液(ye)中(zhong),冷(leng)卻后(hou)加(jia)(jia)(jia)入(ru)(ru)1000mL量(liang)(liang)(liang)筒或量(liang)(liang)(liang)瓶中(zhong),加(jia)(jia)(jia)蒸餾水稀釋(shi)至刻度,最后(hou)測量(liang)(liang)(liang)pH,低了,加(jia)(jia)(jia)少許10%氫(qing)氧化(hua)鈉溶(rong)(rong)液(ye)以便(bian)升高pH;高了,加(jia)(jia)(jia)少許10%硫酸(suan)(suan)溶(rong)(rong)液(ye)以便(bian)降低pH。

5. 操作方法及工藝規范

耗(hao)(hao)電系(xi)數(shu)(shu):0.18A·h/(d㎡2·μm),在循環使用(yong)過程中(zhong)耗(hao)(hao)電系(xi)數(shu)(shu)不變(bian);

工作電壓(ya):6~15V;

接電方式(shi):按(an)正極性連接,工件接負極,鍍筆接正極;

陰陽(yang)極(ji)相對運動速率:10~30m/min;

使用溫度:20~50℃;

在(zai)循環使用過程中(zhong),銅離子(zi)濃度在(zai)剩(sheng)余溶液中(zhong)增加,堿銅刷鍍液屬富(fu)集鍍液。

沉積(ji)速率:12.8μm/min;

鍍層最大厚度:一般為0.02~0.03mm.