熔化極氬弧焊是使用熔化電極(焊絲)的氬氣保護電弧焊,簡稱MIG焊,MICMLIt Gas Arc Welding的縮寫。

一、熔化極氬弧焊的(de)特點

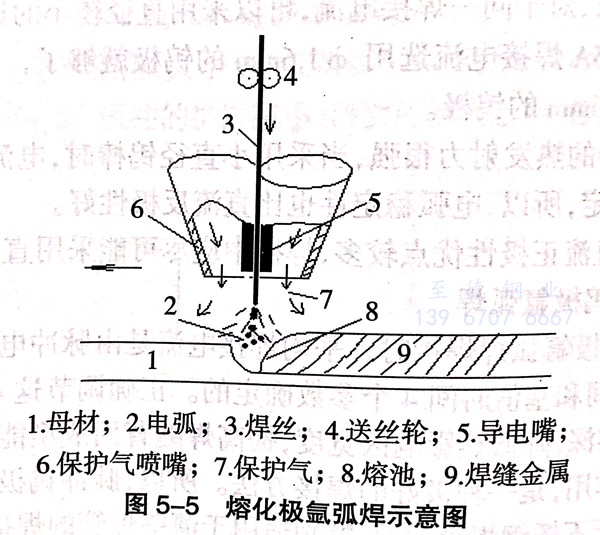

香蕉視頻app下載蘋果版:熔化極氬弧焊的焊接原理如圖5-5所示。熔化極氬弧焊焊接時,焊絲本身既是電極起導電、燃弧的作用,又連續熔化起填充焊縫的作用。因為以氬氣作為保護氣體,因此它不但具有氬弧的特性,還具有以下特點:

1. 生產效率(lv)高

熔化極(ji)(ji)(ji)氬(ya)弧焊(han)與鎢(wu)(wu)極(ji)(ji)(ji)氬(ya)弧焊(han)相(xiang)比,它以焊(han)絲(si)代替(ti)非(fei)熔化的鎢(wu)(wu)極(ji)(ji)(ji),所以能夠承受較大(da)(da)(da)的焊(han)接電(dian)流(liu),電(dian)流(liu)密度大(da)(da)(da)大(da)(da)(da)提(ti)高。例如,Φ1.6mm的鎢(wu)(wu)極(ji)(ji)(ji),在(zai)直(zhi)流(liu)正(zheng)極(ji)(ji)(ji)性(鎢(wu)(wu)極(ji)(ji)(ji)氬(ya)弧焊(han))下最大(da)(da)(da)許用(yong)電(dian)流(liu)為150A,而(er)同(tong)樣直(zhi)徑(Φ1.6mm)的焊(han)絲(si),熔化極(ji)(ji)(ji)氬(ya)弧焊(han)下的焊(han)接電(dian)流(liu)常達350A。因此,熔化極(ji)(ji)(ji)氬(ya)弧焊(han)電(dian)弧功率(lv)大(da)(da)(da),能量集中,熔透能力強(qiang),大(da)(da)(da)大(da)(da)(da)提(ti)高了(le)焊(han)接生產效(xiao)率(lv)。

2. 熔(rong)滴過渡(du)形式便于控(kong)制

熔化極(ji)氬弧焊(han)可實現(xian)不同的熔滴過(guo)渡形式,如短路過(guo)渡、噴射(she)(she)過(guo)渡、亞射(she)(she)流(liu)過(guo)渡和(he)可控脈沖射(she)(she)流(liu)過(guo)渡等,所以,可焊(han)接的工件厚度范(fan)圍較寬,能實現(xian)各種空間(jian)位置或全位置的焊(han)接。

3. 飛濺少

熔(rong)(rong)(rong)(rong)化(hua)(hua)(hua)極(ji)氬弧焊在噴射過(guo)渡(du)時(shi)幾乎無飛(fei)濺(jian)(jian),即(ji)使(shi)在短(duan)(duan)(duan)路(lu)(lu)過(guo)渡(du)時(shi),與二氧化(hua)(hua)(hua)碳(tan)焊相比(bi)飛(fei)濺(jian)(jian)也很少(shao)。由于在氬氣中(zhong)(zhong)電弧的(de)電場強度比(bi)在二氧化(hua)(hua)(hua)碳(tan)氣體中(zhong)(zhong)低,所(suo)以氬弧的(de)陽極(ji)斑點容易(yi)擴展,并籠(long)罩著熔(rong)(rong)(rong)(rong)滴(di)(di)(di)的(de)較大(da)面積,使(shi)熔(rong)(rong)(rong)(rong)滴(di)(di)(di)受力(li)(li)均勻。熔(rong)(rong)(rong)(rong)化(hua)(hua)(hua)極(ji)氬弧焊短(duan)(duan)(duan)路(lu)(lu)過(guo)渡(du)時(shi)熔(rong)(rong)(rong)(rong)滴(di)(di)(di)與熔(rong)(rong)(rong)(rong)池(chi)接觸后,在熔(rong)(rong)(rong)(rong)滴(di)(di)(di)與熔(rong)(rong)(rong)(rong)池(chi)間形成小(xiao)橋,電磁(ci)力(li)(li)和(he)表面張力(li)(li)都(dou)促使(shi)熔(rong)(rong)(rong)(rong)化(hua)(hua)(hua)金(jin)屬過(guo)渡(du)到熔(rong)(rong)(rong)(rong)池(chi)中(zhong)(zhong),有利于熔(rong)(rong)(rong)(rong)滴(di)(di)(di)的(de)短(duan)(duan)(duan)路(lu)(lu)過(guo)渡(du)。所(suo)以熔(rong)(rong)(rong)(rong)化(hua)(hua)(hua)極(ji)氬弧焊短(duan)(duan)(duan)路(lu)(lu)過(guo)渡(du)焊接時(shi),短(duan)(duan)(duan)路(lu)(lu)時(shi)間短(duan)(duan)(duan),并且過(guo)渡(du)比(bi)較規律,短(duan)(duan)(duan)路(lu)(lu)峰值電流(liu)比(bi)較小(xiao),因而飛(fei)濺(jian)(jian)要比(bi)二氧化(hua)(hua)(hua)碳(tan)焊少(shao)得多。

二、 熔化(hua)極氬弧焊(han)的應(ying)用

熔(rong)(rong)化(hua)極(ji)(ji)氬弧焊(han)(han)應(ying)用初期主(zhu)要用來焊(han)(han)接(jie)鋁、鎂及(ji)其(qi)(qi)合(he)金(jin),其(qi)(qi)后由于(yu)富氬混合(he)氣體的(de)廣泛應(ying)用,熔(rong)(rong)化(hua)極(ji)(ji)氬弧焊(han)(han)應(ying)用范(fan)圍不斷擴大,幾乎可以焊(han)(han)接(jie)所有的(de)金(jin)屬(shu),如鋁、鎂、銅(tong)和鎳(nie)及(ji)它們的(de)合(he)金(jin),不銹鋼、碳鋼、低(di)合(he)金(jin)結構鋼等(deng)材(cai)料(liao),尤其(qi)(qi)是焊(han)(han)接(jie)鋁、鎂及(ji)其(qi)(qi)合(he)金(jin)時,采用直流反極(ji)(ji)性有良好(hao)的(de)陰(yin)極(ji)(ji)清理作用,提(ti)高(gao)了焊(han)(han)接(jie)接(jie)頭的(de)質量(liang)。

熔(rong)化(hua)極(ji)氬(ya)弧(hu)焊(han)(han)(han)使用的(de)(de)焊(han)(han)(han)絲,根據其直(zhi)徑的(de)(de)不(bu)同(tong),有細(xi)絲和粗(cu)(cu)(cu)絲之(zhi)分。一般(ban)認(ren)為(wei)(wei),焊(han)(han)(han)絲直(zhi)徑小(xiao)于(yu)ф1.6mm,屬細(xi)絲焊(han)(han)(han);大(da)于(yu)Φ1.6mm,屬粗(cu)(cu)(cu)絲焊(han)(han)(han),粗(cu)(cu)(cu)絲的(de)(de)直(zhi)徑可達Φ6mm.焊(han)(han)(han)絲直(zhi)徑不(bu)同(tong),則(ze)電弧(hu)形態(tai)和使用電流(liu)范圍也不(bu)同(tong)。近年(nian)來,粗(cu)(cu)(cu)絲大(da)電流(liu)熔(rong)化(hua)極(ji)氬(ya)弧(hu)焊(han)(han)(han)得到迅(xun)速(su)發展,通常使用直(zhi)徑為(wei)(wei)Φ3.2mm以(yi)上的(de)(de)粗(cu)(cu)(cu)絲和500A以(yi)上的(de)(de)大(da)電流(liu),也是一種可實(shi)現厚板焊(han)(han)(han)接的(de)(de)高效焊(han)(han)(han)接法(fa)。

三、 熔化極(ji)氬弧焊設(she)備(bei)

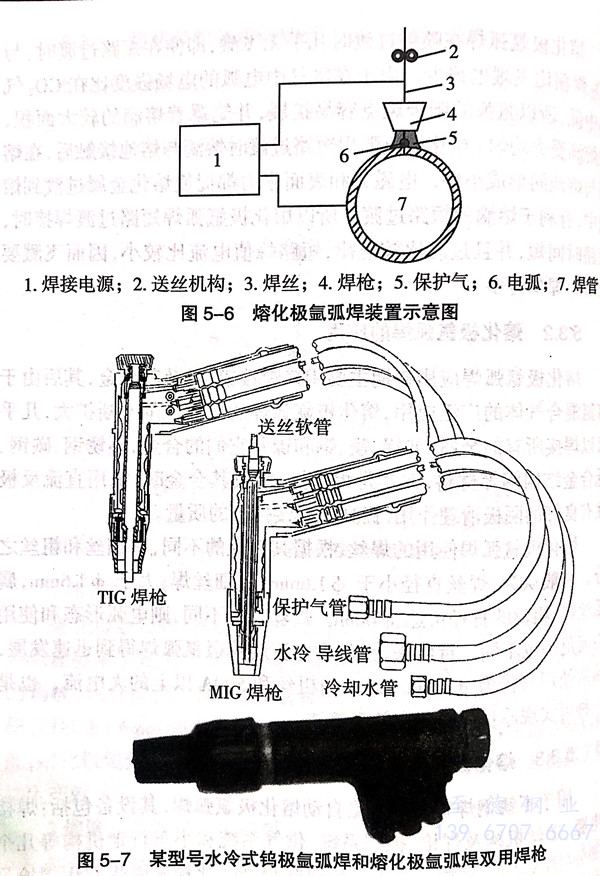

用于香蕉視頻app下載蘋果版:不銹鋼管焊接的是自動熔化極氬弧焊,其設備包括:焊接電源、送絲機構及焊槍、控制系統、供氣系統和小車行走機構等幾個部分(圖5-6).某型號水冷式鎢氬弧焊和熔化極氬弧焊雙用焊槍見圖5-7。