工(gong)(gong)業(ye)管(guan)(guan)(guan)(guan)道器(qi)(qi)(qi)材(cai)選(xuan)(xuan)用是根據工(gong)(gong)程(cheng)設計(ji)的(de)(de)(de)(de)(de)總(zong)體要求、工(gong)(gong)藝數據條件(jian)(jian)和采(cai)購(gou)特點等(deng)因素,對管(guan)(guan)(guan)(guan)子、管(guan)(guan)(guan)(guan)件(jian)(jian)、閥門、法(fa)蘭、墊(dian)片、緊固元件(jian)(jian)、特殊管(guan)(guan)(guan)(guan)道器(qi)(qi)(qi)材(cai)、隔熱(re)材(cai)料(liao)、涂漆材(cai)料(liao)等(deng)的(de)(de)(de)(de)(de)選(xuan)(xuan)用,包括(kuo)管(guan)(guan)(guan)(guan)道材(cai)料(liao)的(de)(de)(de)(de)(de)標準、材(cai)質、規格、結(jie)構(gou)形式、連接形式等(deng)內容的(de)(de)(de)(de)(de)選(xuan)(xuan)定。在國內外一些大(da)型工(gong)(gong)程(cheng)公司,工(gong)(gong)業(ye)管(guan)(guan)(guan)(guan)道器(qi)(qi)(qi)材(cai)選(xuan)(xuan)用的(de)(de)(de)(de)(de)具體工(gong)(gong)作還包括(kuo)管(guan)(guan)(guan)(guan)道材(cai)料(liao)數量匯總(zong)、向采(cai)購(gou)部門提出請(qing)購(gou)單、編制管(guan)(guan)(guan)(guan)道材(cai)料(liao)的(de)(de)(de)(de)(de)采(cai)購(gou)技術要求文(wen)件(jian)(jian)、對管(guan)(guan)(guan)(guan)道材(cai)料(liao)提供商文(wen)件(jian)(jian)的(de)(de)(de)(de)(de)評(ping)閱、施工(gong)(gong)現場(chang)工(gong)(gong)業(ye)管(guan)(guan)(guan)(guan)道器(qi)(qi)(qi)材(cai)的(de)(de)(de)(de)(de)檢(jian)驗和試驗等(deng)內容。工(gong)(gong)業(ye)管(guan)(guan)(guan)(guan)道器(qi)(qi)(qi)材(cai)選(xuan)(xuan)用的(de)(de)(de)(de)(de)工(gong)(gong)作貫穿工(gong)(gong)程(cheng)設計(ji)的(de)(de)(de)(de)(de)整個過程(cheng)。在工(gong)(gong)程(cheng)項目(mu)的(de)(de)(de)(de)(de)詢價、設計(ji)、采(cai)購(gou)、施工(gong)(gong)及后(hou)期服(fu)務等(deng)階(jie)段(duan)均(jun)離不開工(gong)(gong)業(ye)管(guan)(guan)(guan)(guan)道器(qi)(qi)(qi)材(cai)的(de)(de)(de)(de)(de)選(xuan)(xuan)用。

①. 標準(zhun)系列化

目前(qian)大(da)多(duo)數(shu)管道(dao)及(ji)其(qi)(qi)元件都進行了系(xi)(xi)列(lie)(lie)化,并有相(xiang)應(ying)(ying)的(de)應(ying)(ying)用(yong)標(biao)(biao)準(zhun)(zhun)作支持(chi)。因(yin)此(ci),管道(dao)材料設(she)計時首先要考慮的(de)問題就是管道(dao)及(ji)其(qi)(qi)元件標(biao)(biao)準(zhun)(zhun)系(xi)(xi)列(lie)(lie)的(de)選用(yong)。一(yi)個(ge)管系(xi)(xi)中(zhong)(zhong)各(ge)元件所(suo)用(yong)系(xi)(xi)列(lie)(lie)標(biao)(biao)準(zhun)(zhun)的(de)集合(he)稱(cheng)為應(ying)(ying)用(yong)標(biao)(biao)準(zhun)(zhun)體系(xi)(xi)。這些(xie)標(biao)(biao)準(zhun)(zhun)應(ying)(ying)包括管子系(xi)(xi)列(lie)(lie)標(biao)(biao)準(zhun)(zhun)、管件系(xi)(xi)列(lie)(lie)標(biao)(biao)準(zhun)(zhun)、法蘭(lan)及(ji)其(qi)(qi)連接件系(xi)(xi)列(lie)(lie)標(biao)(biao)準(zhun)(zhun)、閥門標(biao)(biao)準(zhun)(zhun)等。這些(xie)標(biao)(biao)準(zhun)(zhun)通過一(yi)定(ding)的(de)規則(ze)在一(yi)個(ge)管系(xi)(xi)中(zhong)(zhong)得到應(ying)(ying)用(yong),它(ta)們之(zhi)間相(xiang)互(hu)銜接、相(xiang)互(hu)配合(he),從而確定(ding)了管道(dao)及(ji)其(qi)(qi)元件的(de)基本參(can)數(shu)。這些(xie)標(biao)(biao)準(zhun)(zhun)中(zhong)(zhong)尤其(qi)(qi)以管子標(biao)(biao)準(zhun)(zhun)和法蘭(lan)標(biao)(biao)準(zhun)(zhun)最具有代(dai)表(biao)性,它(ta)們是其(qi)(qi)他應(ying)(ying)用(yong)標(biao)(biao)準(zhun)(zhun)的(de)基礎。

世界上各(ge)國應(ying)用(yong)的(de)(de)(de)管道(dao)標(biao)(biao)(biao)(biao)準(zhun)(zhun)體(ti)(ti)系(xi)(xi)有很多(duo),不同(tong)的(de)(de)(de)國家有不同(tong)的(de)(de)(de)應(ying)用(yong)標(biao)(biao)(biao)(biao)準(zhun)(zhun)和(he)標(biao)(biao)(biao)(biao)準(zhun)(zhun)體(ti)(ti)系(xi)(xi),而(er)(er)在我(wo)國,不同(tong)的(de)(de)(de)行業(ye)又各(ge)采(cai)(cai)用(yong)不同(tong)的(de)(de)(de)應(ying)用(yong)標(biao)(biao)(biao)(biao)準(zhun)(zhun)和(he)標(biao)(biao)(biao)(biao)準(zhun)(zhun)體(ti)(ti)系(xi)(xi)。這些標(biao)(biao)(biao)(biao)準(zhun)(zhun)之間千差萬別,甚至有些標(biao)(biao)(biao)(biao)準(zhun)(zhun)和(he)標(biao)(biao)(biao)(biao)準(zhun)(zhun)體(ti)(ti)系(xi)(xi)相差甚遠(yuan),相互之間無法配套(tao)使用(yong)和(he)互換(huan),從而(er)(er)給使用(yong)者帶來了不少麻(ma)煩。為(wei)此(ci),工業(ye)管道(dao)設計(ji)的(de)(de)(de)第一步(bu)就是選擇應(ying)用(yong)標(biao)(biao)(biao)(biao)準(zhun)(zhun)體(ti)(ti)系(xi)(xi),并作為(wei)裝置內各(ge)個專業(ye)設計(ji)的(de)(de)(de)統一規(gui)定(ding),以避免各(ge)相關專業(ye)因采(cai)(cai)用(yong)不能互換(huan)的(de)(de)(de)其(qi)他應(ying)用(yong)標(biao)(biao)(biao)(biao)準(zhun)(zhun)體(ti)(ti)系(xi)(xi)而(er)(er)導致錯誤。

工程(cheng)應用:配管設(she)計的(de)管子標(biao)準系(xi)列不同引起的(de)錯誤(wu)

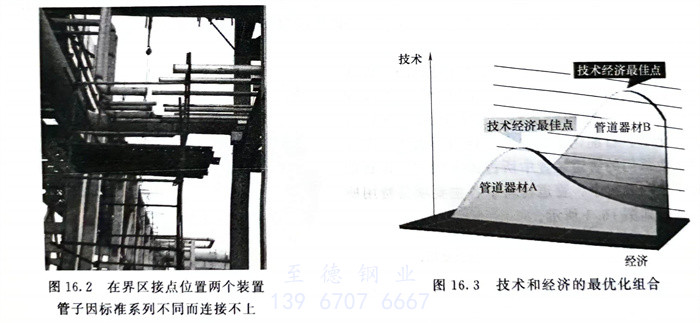

圖16.2所(suo)示的是(shi)(shi)在某(mou)施工現(xian)場發(fa)現(xian)的,因設計(ji)引起(qi)的錯誤。兩個裝(zhuang)置在界(jie)區接點,因管(guan)(guan)子(zi)標(biao)準系列不同引起(qi)管(guan)(guan)子(zi)外(wai)徑(jing)不同而連接不上。左側為(wei)ASME標(biao)準管(guan)(guan)子(zi),右(you)側為(wei)HG 20553II標(biao)準系列管(guan)(guan)子(zi),都(dou)是(shi)(shi)DN500的公稱直徑(jing),但是(shi)(shi)左側管(guan)(guan)子(zi)外(wai)徑(jing)為(wei)508mm,右(you)側管(guan)(guan)子(zi)外(wai)徑(jing)為(wei)530mm。

②. 國際(ji)化

現在(zai)的工(gong)程(cheng)項目(mu)越來越國(guo)(guo)際化(hua),這就(jiu)要求工(gong)業管道器材(cai)設計時(shi)按照工(gong)程(cheng)項目(mu)的具(ju)體要求,選(xuan)用(yong)國(guo)(guo)際化(hua)標準(zhun)(zhun)的管道器材(cai)。管道器材(cai)選(xuan)用(yong)設計標準(zhun)(zhun)規(gui)范也逐(zhu)漸在(zai)統(tong)一(yi)向通用(yong)的國(guo)(guo)際化(hua)標準(zhun)(zhun)看齊。

③. 經濟性

經(jing)濟性是指管(guan)道的一次(ci)投資(zi)費用和(he)操(cao)(cao)作維護費用的綜合指數低。一般(ban)情況下(xia),如果一次(ci)投資(zi)較高的話,其可靠性好,操(cao)(cao)作、維護費用低。對于特別重(zhong)大和(he)復雜的決策,可借助計(ji)算機分(fen)析取(qu)技術和(he)經(jing)濟的最優化組合,如圖16.3所示。在(zai)設計(ji)時,要力爭(zheng)做到管(guan)系中各元件(jian)具有相同的強度和(he)壽命選用。

④. 多學科性

工(gong)(gong)業(ye)管(guan)道器(qi)材(cai)設計是配管(guan)設計的(de)(de)基(ji)礎技能(neng)之(zhi)一,工(gong)(gong)業(ye)管(guan)道器(qi)材(cai)設計既要(yao)求(qiu)從事這項設計的(de)(de)工(gong)(gong)程技術人員具有材(cai)料、力(li)學、機(ji)械、技術經濟等多(duo)學科(ke)知識,還要(yao)求(qiu)能(neng)夠運用(yong)好計算機(ji)和(he)外語兩(liang)個(ge)最重要(yao)的(de)(de)工(gong)(gong)具,結(jie)合項目實(shi)際的(de)(de)采購情況,根(gen)據(ju)工(gong)(gong)藝專業(ye)的(de)(de)工(gong)(gong)藝管(guan)道數據(ju)表(biao)要(yao)求(qiu),根(gen)據(ju)管(guan)道布置(zhi)、設備(bei)布置(zhi)和(he)管(guan)道應(ying)力(li)分析(xi)的(de)(de)特殊要(yao)求(qiu),根(gen)據(ju)甲(jia)方提出的(de)(de)要(yao)求(qiu),并遵循相(xiang)關法規和(he)規定,用(yong)計算機(ji)文本、表(biao)格(ge)或者(zhe)數據(ju)庫表(biao)示出來,成(cheng)為一個(ge)系統(tong)的(de)(de)、集體(ti)的(de)(de)、創造性(xing)的(de)(de)智力(li)勞動。

⑤. 復雜性

工(gong)業(ye)管(guan)(guan)道(dao)(dao)工(gong)程設計過(guo)程中實(shi)際應用(yong)(yong)的管(guan)(guan)道(dao)(dao)器(qi)(qi)材種類很多,使用(yong)(yong)工(gong)況也千差萬別(bie),影(ying)響因素和環節也比較多。工(gong)業(ye)管(guan)(guan)道(dao)(dao)是一(yi)個系統,各環節相(xiang)互(hu)關聯、相(xiang)互(hu)影(ying)響,管(guan)(guan)道(dao)(dao)組成(cheng)件(jian)和管(guan)(guan)道(dao)(dao)支撐(cheng)件(jian)的種類繁(fan)多,各種材料(liao)各有(you)特(te)點和具體(ti)技術要(yao)求(qiu),材料(liao)選用(yong)(yong)復(fu)雜。管(guan)(guan)道(dao)(dao)長徑比很大,極(ji)易失穩(wen),受力(li)情(qing)況比壓(ya)力(li)容器(qi)(qi)更復(fu)雜。管(guan)(guan)道(dao)(dao)內(nei)流(liu)體(ti)流(liu)動狀態復(fu)雜,緩沖余地小(xiao),工(gong)作條(tiao)件(jian)變化頻(pin)率(lv)比壓(ya)力(li)容器(qi)(qi)高(如高溫、高壓(ya)、低溫、低壓(ya)、位(wei)移變形、風(feng)、雪、地震等都可能(neng)(neng)影(ying)響管(guan)(guan)道(dao)(dao)受力(li)情(qing)況)。在做(zuo)管(guan)(guan)道(dao)(dao)器(qi)(qi)材選用(yong)(yong)工(gong)作時(shi)需要(yao)全面考慮(lv)。管(guan)(guan)道(dao)(dao)器(qi)(qi)材選用(yong)(yong)和裝置布(bu)(bu)置、管(guan)(guan)道(dao)(dao)布(bu)(bu)置、配管(guan)(guan)應力(li)分析一(yi)樣都是完成(cheng)工(gong)程項(xiang)目配管(guan)(guan)(管(guan)(guan)道(dao)(dao))設計專業(ye)工(gong)作的基本(ben)技術技能(neng)(neng)。