埋弧焊不銹鋼管焊接參數比焊條電弧焊多一些,包括焊接電流、電弧電壓、焊接速度、焊接材料、焊絲直徑、焊絲偏移量、焊絲干伸長度、焊絲輸送速度等。

①. 焊接電流

焊(han)接(jie)電(dian)流(liu)的(de)(de)(de)(de)大(da)(da)小(xiao)(xiao)直接(jie)影(ying)響焊(han)接(jie)熔(rong)池的(de)(de)(de)(de)深淺,焊(han)接(jie)電(dian)流(liu)大(da)(da),熱(re)輸入大(da)(da)、電(dian)弧挺度大(da)(da),焊(han)接(jie)熔(rong)池深;反之(zhi)(zhi)則(ze)淺。當焊(han)接(jie)電(dian)流(liu)較(jiao)大(da)(da)時,由(you)于熔(rong)深較(jiao)深,而(er)焊(han)縫(feng)寬度變化不大(da)(da),所得(de)到的(de)(de)(de)(de)焊(han)縫(feng)成形系(xi)數(shu)(焊(han)縫(feng)的(de)(de)(de)(de)寬度與焊(han)縫(feng)有效(xiao)厚度的(de)(de)(de)(de)比(bi)值稱為(wei)焊(han)縫(feng)成形系(xi)數(shu))較(jiao)小(xiao)(xiao)。這樣的(de)(de)(de)(de)焊(han)縫(feng),對(dui)(dui)熔(rong)池中氣(qi)體和夾渣物的(de)(de)(de)(de)上浮和溢出(chu)十分不利,易(yi)產生氣(qi)孔(kong)、夾渣和熱(re)裂紋。所以(yi)一般(ban)增加電(dian)流(liu)時,必須相應的(de)(de)(de)(de)提高電(dian)弧電(dian)壓,以(yi)保證得(de)到合理的(de)(de)(de)(de)焊(han)縫(feng)形狀,一般(ban)焊(han)縫(feng)成形系(xi)數(shu)控制在1.3~2.0之(zhi)(zhi)間,這樣對(dui)(dui)熔(rong)池中的(de)(de)(de)(de)氣(qi)體溢出(chu)以(yi)及(ji)防止產生夾渣或(huo)熱(re)裂紋等缺陷有利。

②. 電弧電壓

電(dian)(dian)(dian)弧(hu)(hu)電(dian)(dian)(dian)壓(ya)隨著(zhu)電(dian)(dian)(dian)弧(hu)(hu)長度(du)的變(bian)化(hua)而(er)變(bian)化(hua),電(dian)(dian)(dian)弧(hu)(hu)拉長了,電(dian)(dian)(dian)弧(hu)(hu)電(dian)(dian)(dian)壓(ya)則升高,電(dian)(dian)(dian)弧(hu)(hu)挺(ting)度(du)下降,母材(cai)受(shou)熱面增(zeng)加(jia)(jia),所以(yi)焊(han)接熔池的深度(du)減小,焊(han)縫寬度(du)明顯增(zeng)寬。適當的增(zeng)加(jia)(jia)電(dian)(dian)(dian)弧(hu)(hu)電(dian)(dian)(dian)壓(ya),會(hui)提高焊(han)縫質(zhi)量,但應與增(zeng)加(jia)(jia)焊(han)接電(dian)(dian)(dian)流相配合。單純地增(zeng)加(jia)(jia)電(dian)(dian)(dian)弧(hu)(hu)電(dian)(dian)(dian)壓(ya),會(hui)使熔深減小,造(zao)成焊(han)件未(wei)焊(han)透。而(er)且焊(han)劑(ji)的熔化(hua)量大,增(zeng)加(jia)(jia)焊(han)劑(ji)的消耗量。焊(han)縫表面粗糙,脫渣(zha)困難,嚴重時,會(hui)造(zao)成焊(han)縫邊(bian)緣咬(yao)邊(bian)。

③. 焊接速度

當焊(han)(han)接(jie)電流和電弧(hu)(hu)電壓不(bu)變時,焊(han)(han)接(jie)速度(du)(du)提(ti)高,電弧(hu)(hu)給予焊(han)(han)接(jie)熔(rong)(rong)池中(zhong)單位長(chang)度(du)(du)的熱量勢必減少,導致(zhi)焊(han)(han)縫(feng)熔(rong)(rong)深和焊(han)(han)縫(feng)寬度(du)(du)減小。過分的增加焊(han)(han)接(jie)速度(du)(du),會導致(zhi)焊(han)(han)接(jie)電弧(hu)(hu)對工件的加熱不(bu)足,造成焊(han)(han)件未(wei)(wei)焊(han)(han)透和邊(bian)緣未(wei)(wei)熔(rong)(rong)合(he)等缺陷。

④. 焊接材料

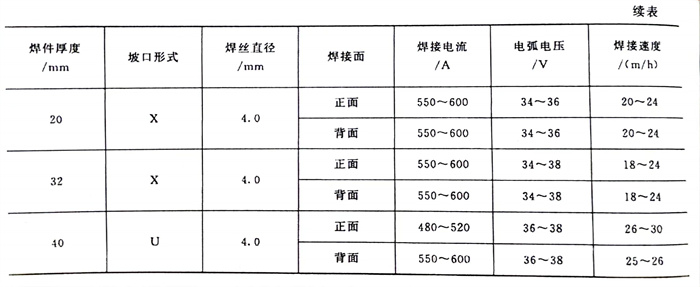

a. 壓力容器常用(yong)(yong)不銹鋼(gang)埋(mai)弧(hu)(hu)焊(han)(han)(han)焊(han)(han)(han)絲(si)、焊(han)(han)(han)劑(ji)見表(biao)4-14,常用(yong)(yong)奧氏(shi)體(ti)型耐熱鋼(gang)埋(mai)弧(hu)(hu)焊(han)(han)(han)焊(han)(han)(han)劑(ji)與焊(han)(han)(han)絲(si)見表(biao)4-15,結構件常用(yong)(yong)奧氏(shi)體(ti)不銹鋼(gang)埋(mai)弧(hu)(hu)焊(han)(han)(han)焊(han)(han)(han)劑(ji)與焊(han)(han)(han)絲(si)見表(biao)4-16。

b. 常用不銹鋼埋弧焊用焊劑烘(hong)焙(bei)要求(qiu)見(jian)表 4-17 。

c. 焊(han)(han)劑顆粒度(du)。熔煉焊(han)(han)劑顆粒度(du)為2.5~0.45mm(4~40目(mu)),燒結焊(han)(han)劑顆粒度(du)為2~0.28mm(10~60目(mu)),焊(han)(han)劑允許(xu)重(zhong)復使用(yong),但重(zhong)復使用(yong)前(qian)須篩出細粉和(he)渣(zha)殼(ke),并與新焊(han)(han)劑混勻后使用(yong)。

⑤. 焊絲直徑

焊絲直徑加粗,電(dian)弧(hu)范圍擴大,使熔寬增加;如果(guo)焊接電(dian)流(liu)保(bao)持不變,電(dian)流(liu)密度減(jian)小,電(dian)弧(hu)挺(ting)度下(xia)降(jiang),則熔深將(jiang)相應地減(jian)小。

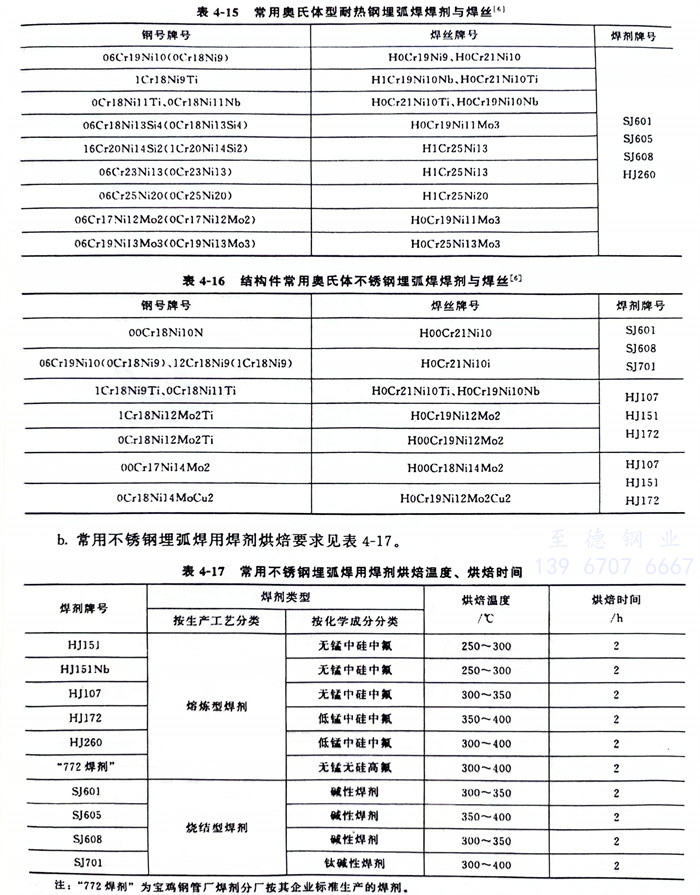

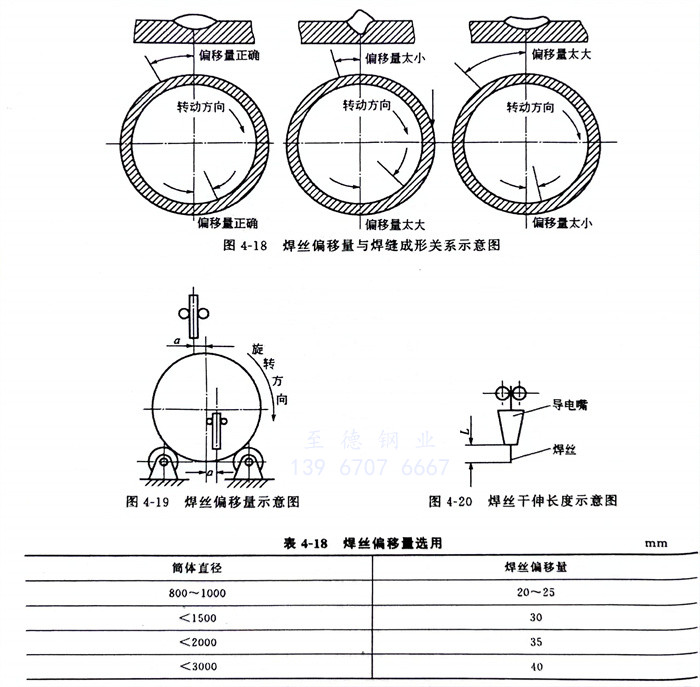

⑥. 焊絲偏移量a

焊(han)(han)(han)(han)(han)接(jie)環焊(han)(han)(han)(han)(han)縫(feng)時(shi),焊(han)(han)(han)(han)(han)絲(si)(si)(si)(si)(si)不應在最高點(dian)或最低點(dian),而應在下坡焊(han)(han)(han)(han)(han)的位置上,如(ru)圖4-19所示。焊(han)(han)(han)(han)(han)絲(si)(si)(si)(si)(si)偏(pian)(pian)(pian)移(yi)量(liang)直接(jie)影(ying)響焊(han)(han)(han)(han)(han)縫(feng)成形(xing),見圖4-18。焊(han)(han)(han)(han)(han)絲(si)(si)(si)(si)(si)偏(pian)(pian)(pian)移(yi)量(liang)與焊(han)(han)(han)(han)(han)件(jian)外徑(jing)(jing)和焊(han)(han)(han)(han)(han)接(jie)線能(neng)(neng)量(liang)有關。當焊(han)(han)(han)(han)(han)接(jie)線能(neng)(neng)量(liang)大(da)(da)時(shi),熔(rong)池(chi)停(ting)留時(shi)間較(jiao)(jiao)(jiao)長(chang),所以焊(han)(han)(han)(han)(han)絲(si)(si)(si)(si)(si)偏(pian)(pian)(pian)移(yi)量(liang)可(ke)選較(jiao)(jiao)(jiao)大(da)(da)值。當焊(han)(han)(han)(han)(han)接(jie)線能(neng)(neng)量(liang)小時(shi),熔(rong)池(chi)停(ting)留時(shi)間較(jiao)(jiao)(jiao)短,所以焊(han)(han)(han)(han)(han)絲(si)(si)(si)(si)(si)偏(pian)(pian)(pian)移(yi)量(liang)選取較(jiao)(jiao)(jiao)小值。當焊(han)(han)(han)(han)(han)件(jian)外徑(jing)(jing)較(jiao)(jiao)(jiao)大(da)(da)時(shi),熔(rong)池(chi)中(zhong)的液(ye)態金(jin)屬外溢的傾向(xiang)較(jiao)(jiao)(jiao)小,此(ci)時(shi),焊(han)(han)(han)(han)(han)絲(si)(si)(si)(si)(si)偏(pian)(pian)(pian)移(yi)量(liang)可(ke)取較(jiao)(jiao)(jiao)大(da)(da)值。焊(han)(han)(han)(han)(han)絲(si)(si)(si)(si)(si)直徑(jing)(jing)小于3mm時(shi),焊(han)(han)(han)(han)(han)絲(si)(si)(si)(si)(si)偏(pian)(pian)(pian)移(yi)量(liang)一(yi)般不超(chao)過5~10mm,焊(han)(han)(han)(han)(han)絲(si)(si)(si)(si)(si)直徑(jing)(jing)大(da)(da)于3mm時(shi),焊(han)(han)(han)(han)(han)絲(si)(si)(si)(si)(si)偏(pian)(pian)(pian)移(yi)量(liang)見表(biao)4-18。

⑦. 焊絲干伸長度(du)L

焊(han)絲(si)前端(duan)到導電嘴前端(duan)的(de)距(ju)離(li)稱為焊(han)絲(si)干(gan)伸(shen)(shen)長(chang)度(du),見圖4-20。焊(han)絲(si)干(gan)伸(shen)(shen)長(chang)度(du)L增(zeng)(zeng)加(jia)(jia)(jia),焊(han)絲(si)的(de)預(yu)熱溫度(du)增(zeng)(zeng)加(jia)(jia)(jia),焊(han)絲(si)熔化速度(du)增(zeng)(zeng)加(jia)(jia)(jia),增(zeng)(zeng)加(jia)(jia)(jia)焊(han)絲(si)干(gan)伸(shen)(shen)長(chang)度(du)可(ke)提高生產效率,但焊(han)絲(si)干(gan)伸(shen)(shen)長(chang)度(du)超(chao)過(guo)50mm后會(hui)出現成段爆裂現象。所以焊(han)絲(si)干(gan)伸(shen)(shen)長(chang)度(du)一般控制在17~20mm范(fan)圍內。

⑧. 電(dian)流種類和電(dian)極(ji)(ji)極(ji)(ji)性(xing)

在一(yi)般情況(kuang)下,電(dian)弧(hu)(hu)陽(yang)極(ji)區(qu)(qu)的(de)(de)(de)溫度(du)(du)較陰極(ji)區(qu)(qu)的(de)(de)(de)溫度(du)(du)高,但在使(shi)用(yong)高錳(meng)高硅含氟的(de)(de)(de)焊(han)劑進行埋弧(hu)(hu)焊(han)時,電(dian)弧(hu)(hu)空間氣體的(de)(de)(de)電(dian)離勢增(zeng)(zeng)(zeng)加(jia)(jia),這樣,氣體電(dian)離后(hou)正離子釋放至陰極(ji)的(de)(de)(de)能量也增(zeng)(zeng)(zeng)加(jia)(jia),使(shi)陰極(ji)的(de)(de)(de)溫度(du)(du)提高,并大(da)于(yu)陽(yang)極(ji)的(de)(de)(de)溫度(du)(du)。因而在用(yong)含有高電(dian)離電(dian)位的(de)(de)(de)埋弧(hu)(hu)焊(han)劑時,若焊(han)接(jie)電(dian)源(yuan)(yuan)為直(zhi)流正接(jie),則(ze)焊(han)絲的(de)(de)(de)熔(rong)(rong)(rong)化速度(du)(du)大(da)于(yu)焊(han)件的(de)(de)(de)熔(rong)(rong)(rong)化速度(du)(du),使(shi)接(jie)頭熔(rong)(rong)(rong)深減小,焊(han)縫余高增(zeng)(zeng)(zeng)加(jia)(jia)。反(fan)之用(yong)直(zhi)流反(fan)接(jie)便可增(zeng)(zeng)(zeng)加(jia)(jia)熔(rong)(rong)(rong)深。使(shi)用(yong)交流焊(han)接(jie)電(dian)源(yuan)(yuan)時,對形狀的(de)(de)(de)影響介于(yu)直(zhi)流正接(jie)、反(fan)接(jie)之間。

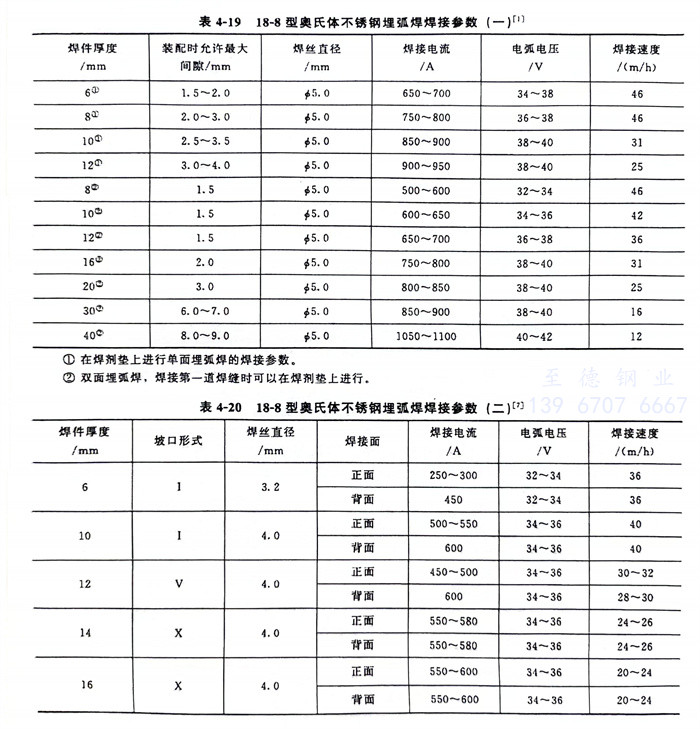

上(shang)述各項焊(han)(han)接(jie)(jie)參(can)(can)數的選擇,不(bu)能(neng)(neng)單項考(kao)慮(lv),要(yao)有機地(di)匹配,進行綜合平衡分析(xi),找(zhao)出一個主要(yao)焊(han)(han)接(jie)(jie)參(can)(can)數,在(zai)充分試驗(yan)后(hou),才能(neng)(neng)制訂出最(zui)佳參(can)(can)數。最(zui)終要(yao)經過焊(han)(han)接(jie)(jie)接(jie)(jie)頭的力學性能(neng)(neng)考(kao)核和耐腐蝕(shi)性能(neng)(neng)試驗(yan)(即焊(han)(han)接(jie)(jie)工藝評(ping)定合格),滿(man)足產品設(she)計(ji)圖樣要(yao)求后(hou),方能(neng)(neng)在(zai)產品上(shang)正式施焊(han)(han)。表(biao)4-19、表(biao)4-20所(suo)列出的18-8型奧氏體不(bu)銹鋼焊(han)(han)接(jie)(jie)參(can)(can)數可供參(can)(can)考(kao)。