不銹(xiu)鋼壓力容器(qi)和(he)管(guan)路(lu)的(de)對接焊(han)(han)(han)縫(feng)須(xu)保證完全(quan)焊(han)(han)(han)透(tou),但在(zai)焊(han)(han)(han)接直(zhi)徑小或(huo)無法實現雙面(mian)焊(han)(han)(han)時,對接焊(han)(han)(han)縫(feng)須(xu)采用單(dan)面(mian)焊(han)(han)(han)背面(mian)成形(xing)的(de)方法來保證焊(han)(han)(han)縫(feng)背面(mian)焊(han)(han)(han)透(tou)。單(dan)面(mian)焊(han)(han)(han)時易(yi)造成內表(biao)面(mian)未焊(han)(han)(han)透(tou)或(huo)出現焊(han)(han)(han)瘤(liu)和(he)咬邊(bian)等焊(han)(han)(han)接缺(que)欠(qian),影響接頭的(de)焊(han)(han)(han)接質量。為此,提(ti)出了單(dan)面(mian)焊(han)(han)(han)背面(mian)成形(xing)的(de)焊(han)(han)(han)接操作(zuo)方法。

單面(mian)焊背(bei)(bei)(bei)面(mian)成形(xing)操作(zuo)方法是一種高(gao)技巧的操作(zuo)技術,要求在焊件(jian)(jian)坡(po)口(kou)背(bei)(bei)(bei)面(mian)沒有任何輔助(zhu)措施的條件(jian)(jian)下,在坡(po)口(kou)正面(mian)進行(xing)焊接,且焊后保證坡(po)口(kou)正面(mian)、背(bei)(bei)(bei)面(mian)都有一定的焊縫余高(gao),且焊縫均勻整齊、成形(xing)良好。

①. 接頭形式

適用于焊(han)條電弧焊(han)單面焊(han)背(bei)面成形的接(jie)(jie)(jie)(jie)頭形式(shi),主要有板狀對接(jie)(jie)(jie)(jie)接(jie)(jie)(jie)(jie)頭(對接(jie)(jie)(jie)(jie)焊(han)縫(feng)(feng)(feng))、管(guan)狀對接(jie)(jie)(jie)(jie)接(jie)(jie)(jie)(jie)頭(對接(jie)(jie)(jie)(jie)焊(han)縫(feng)(feng)(feng))和插(cha)入式(shi)管(guan)與殼(ke)體(ti)接(jie)(jie)(jie)(jie)頭(對接(jie)(jie)(jie)(jie)焊(han)縫(feng)(feng)(feng)加(jia)角(jiao)焊(han)縫(feng)(feng)(feng))、騎座式(shi)管(guan)與殼(ke)體(ti)接(jie)(jie)(jie)(jie)頭(對接(jie)(jie)(jie)(jie)焊(han)縫(feng)(feng)(feng)加(jia)角(jiao)焊(han)縫(feng)(feng)(feng))。

②. 焊接位置

按焊(han)接接頭(tou)所處位(wei)置(zhi)(zhi),可選(xuan)擇平焊(han)、立焊(han)、橫焊(han)和仰焊(han)等位(wei)置(zhi)(zhi)進行施焊(han)。這種單面焊(han)背面成(cheng)形(xing)的焊(han)接操(cao)作方法(fa)一般適用(yong)于(yu)V形(xing)坡口且鈍邊較(jiao)小的對(dui)接焊(han)縫(feng)。

③. 電弧燃(ran)燒方式(shi)

焊(han)條電弧焊(han)單(dan)面(mian)(mian)焊(han)背面(mian)(mian)成(cheng)形的(de)焊(han)縫,可通過間斷(duan)滅弧焊(han)方式(又(you)稱(cheng)斷(duan)弧焊(han)法(fa),或稱(cheng)閃弧焊(han)法(fa))或連(lian)弧焊(han)方式來(lai)實現。

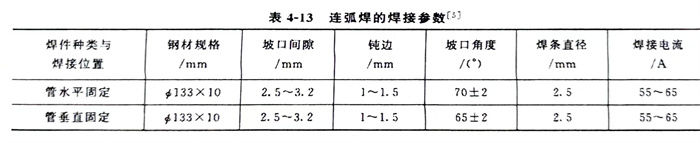

a. 間斷滅弧焊(han)(han)(han)方式是在焊(han)(han)(han)接(jie)過程中,利用(yong)電弧的(de)短時反復點(dian)燃(ran)和熄滅來控(kong)制焊(han)(han)(han)縫成(cheng)形(xing),即電弧燃(ran)燒時加熱熔透坡口根部,形(xing)成(cheng)熔合良好(hao)的(de)熔池(chi);電弧熄滅時,將(jiang)熔池(chi)結晶形(xing)成(cheng)雙面(mian)焊(han)(han)(han)縫(背面(mian)自由成(cheng)形(xing))。斷弧焊(han)(han)(han)的(de)焊(han)(han)(han)接(jie)參數見表(biao)4-12。

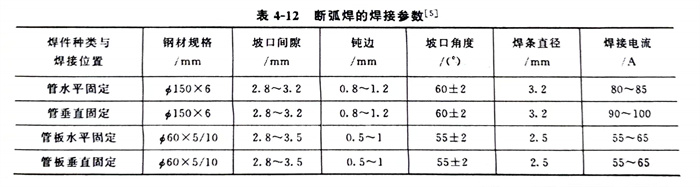

b. 連弧(hu)(hu)(hu)焊(han)(han)(han)方(fang)式是電弧(hu)(hu)(hu)在整(zheng)個焊(han)(han)(han)接(jie)(jie)(jie)過(guo)程中連續燃燒,不熄(xi)弧(hu)(hu)(hu),其(qi)運條操作方(fang)法(fa)又有(you)挑(tiao)弧(hu)(hu)(hu)法(fa)和穩(wen)定電弧(hu)(hu)(hu)焊(han)(han)(han)法(fa)之分。穩(wen)弧(hu)(hu)(hu)法(fa)也可(ke)借助電流(liu)調(diao)節器,引弧(hu)(hu)(hu)時(shi)把電流(liu)調(diao)得稍大些(xie),便于引弧(hu)(hu)(hu)段(duan)焊(han)(han)(han)透(tou),電弧(hu)(hu)(hu)引燃后再(zai)調(diao)至正常,轉為正常焊(han)(han)(han)接(jie)(jie)(jie),收尾時(shi)再(zai)將焊(han)(han)(han)接(jie)(jie)(jie)電流(liu)調(diao)小些(xie),有(you)些(xie)弧(hu)(hu)(hu)焊(han)(han)(han)整(zheng)流(liu)器已(yi)增(zeng)添了此功能。挑(tiao)弧(hu)(hu)(hu)法(fa)是指焊(han)(han)(han)條在坡(po)口(kou)兩側擺動(dong),當形成熔(rong)池時(shi),電弧(hu)(hu)(hu)離開熔(rong)池到(dao)坡(po)口(kou)邊(bian)緣(yuan),待熔(rong)池凝固(gu)的瞬間,停在坡(po)口(kou)邊(bian)緣(yuan)的電弧(hu)(hu)(hu)迅速(su)移至熔(rong)池處,重新進行焊(han)(han)(han)接(jie)(jie)(jie)。連弧(hu)(hu)(hu)焊(han)(han)(han)的焊(han)(han)(han)接(jie)(jie)(jie)參數見表(biao)4-13。