藥芯(xin)焊絲根(gen)據其內層填料中有(you)無造(zao)渣(zha)(zha)劑(ji)(ji),分(fen)為藥粉型(xing)(有(you)造(zao)渣(zha)(zha)劑(ji)(ji))焊絲和金屬粉型(xing)(無造(zao)渣(zha)(zha)劑(ji)(ji))焊絲兩種。

有(you)造(zao)渣(zha)劑的(de)按照渣(zha)的(de)堿(jian)度,可(ke)分(fen)為鈦型(xing)(酸(suan)性(xing)渣(zha))、鈣(gai)鈦型(xing)(中性(xing)或弱堿(jian)性(xing)渣(zha))和鈣(gai)型(xing)(堿(jian)性(xing)渣(zha))的(de)焊(han)(han)(han)絲。鈦型(xing)渣(zha)系(xi)的(de)焊(han)(han)(han)縫成形美觀,可(ke)進行全(quan)位置焊(han)(han)(han)接,電弧(hu)穩(wen)定(ding),飛濺很(hen)少,焊(han)(han)(han)接工藝性(xing)能優良(liang)(liang),但焊(han)(han)(han)縫的(de)韌性(xing)和抗裂性(xing)能略差。鈣(gai)型(xing)渣(zha)系(xi)的(de)焊(han)(han)(han)縫韌性(xing)和抗裂性(xing)能優良(liang)(liang),而焊(han)(han)(han)縫成形和焊(han)(han)(han)接工藝性(xing)能稍差。鈣(gai)鈦型(xing)渣(zha)系(xi)介于上述兩(liang)者之間。

無(wu)造(zao)(zao)渣劑(ji)(ji)藥芯(xin)焊(han)絲(si)(si)(si)的(de)焊(han)接(jie)工藝性(xing)能(neng)類似于實心(xin)焊(han)絲(si)(si)(si),其(qi)熔敷效率和(he)(he)抗裂(lie)性(xing)能(neng)優于有(you)造(zao)(zao)渣劑(ji)(ji)藥芯(xin)焊(han)絲(si)(si)(si)。無(wu)造(zao)(zao)渣劑(ji)(ji)藥芯(xin)成分(fen)中大部(bu)分(fen)是金屬(shu)粉,還加入了特殊(shu)的(de)穩(wen)(wen)弧(hu)劑(ji)(ji),能(neng)保證焊(han)接(jie)時造(zao)(zao)渣少,效率高(gao)(gao)、飛濺少和(he)(he)電弧(hu)穩(wen)(wen)定(ding)等特點。此(ci)外,它還具有(you)焊(han)縫擴散氫含量低的(de)特點,能(neng)提高(gao)(gao)焊(han)接(jie)接(jie)頭的(de)抗裂(lie)性(xing)能(neng)。據統計(ji),采用無(wu)造(zao)(zao)渣劑(ji)(ji)藥芯(xin)焊(han)絲(si)(si)(si)施焊(han)時,其(qi)造(zao)(zao)渣量只(zhi)有(you)有(you)造(zao)(zao)渣劑(ji)(ji)焊(han)絲(si)(si)(si)的(de)1/3,所以不需除(chu)渣就可進行連(lian)續多層(ceng)焊(han)接(jie)(3~4層(ceng)),可大大提高(gao)(gao)焊(han)接(jie)生(sheng)產效率。

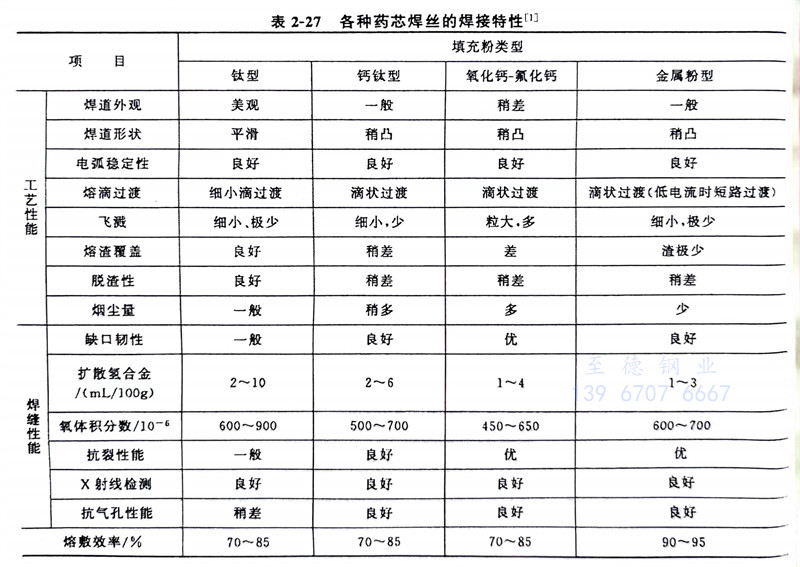

各種藥芯(xin)焊絲的焊接特性見表2-27。