高頻感應(ying)加(jia)(jia)熱(re)表面淬(cui)火法是(shi)將工(gong)(gong)件(jian)(jian)放在由(you)空心銅管繞制(zhi)的感應(ying)器中,然后向(xiang)感應(ying)器通入(ru)一(yi)定頻率的交流電,以產(chan)生交變磁(ci)場,使(shi)工(gong)(gong)件(jian)(jian)內產(chan)生頻率相同的感應(ying)電流,使(shi)工(gong)(gong)件(jian)(jian)表面加(jia)(jia)熱(re)到淬(cui)火溫(wen)(wen)度(du),而心部溫(wen)(wen)度(du)仍(reng)接近于室溫(wen)(wen),隨(sui)后噴冷(leng)卻(que)介質或把加(jia)(jia)熱(re)后的工(gong)(gong)件(jian)(jian)放入(ru)冷(leng)卻(que)介質中快速冷(leng)卻(que),就能(neng)達到工(gong)(gong)件(jian)(jian)表面加(jia)(jia)熱(re)淬(cui)火的目的。

高頻感(gan)應(ying)加熱表面(mian)(mian)淬火(huo)是我國機(ji)械(xie)行業中較普(pu)遍應(ying)用的(de)表面(mian)(mian)淬火(huo)方(fang)法。高頻感(gan)應(ying)加熱表面(mian)(mian)淬火(huo)對工(gong)件的(de)原始組織有一定要求,應(ying)預正火(huo)或調質處理,以(yi)使(shi)工(gong)件基體有較好的(de)綜合(he)力學(xue)性能。高頻感(gan)應(ying)表面(mian)(mian)加 熱淬火(huo)后的(de)工(gong)件需進行低溫回火(huo),以(yi)降低淬火(huo)產生(sheng)的(de)內應(ying)力。

高(gao)頻感(gan)應加熱表(biao)(biao)面(mian)(mian)淬火是(shi)一種先進的熱處理方法(fa),它(ta)的特點是(shi)加熱速度快(kuai)、淬火組織細、硬度比(bi)普通淬火高(gao)2~3HRC,耐磨性提高(gao),表(biao)(biao)面(mian)(mian)氧化,脫碳極(ji)微(wei)。

以極大(da)(da)密(mi)度(du)(du)的(de)能(neng)量(liang)(>103W/c㎡)瞬時(shi)(shi)供給被處(chu)(chu)(chu)理(li)(li)(li)(li)工(gong)件的(de)表面(mian),使其發(fa)(fa)生(sheng)(sheng)相(xiang)變硬(ying)化,熔化快速凝固和表面(mian)合金化效果的(de)熱(re)(re)(re)處(chu)(chu)(chu)理(li)(li)(li)(li)稱(cheng)高(gao)(gao)密(mi)度(du)(du)能(neng)(也稱(cheng)高(gao)(gao)能(neng)密(mi)度(du)(du))加(jia)熱(re)(re)(re)熱(re)(re)(re)處(chu)(chu)(chu)理(li)(li)(li)(li),也稱(cheng)沖(chong)(chong)(chong)擊(ji)熱(re)(re)(re)處(chu)(chu)(chu)理(li)(li)(li)(li)法,沖(chong)(chong)(chong)擊(ji)熱(re)(re)(re)處(chu)(chu)(chu)理(li)(li)(li)(li)也可(ke)(ke)以靠(kao)高(gao)(gao)頻(pin)感(gan)應(ying)(ying)(ying)加(jia)熱(re)(re)(re)法來(lai)實現。高(gao)(gao)頻(pin)脈(mo)沖(chong)(chong)(chong)感(gan)應(ying)(ying)(ying)加(jia)熱(re)(re)(re)時(shi)(shi),發(fa)(fa)生(sheng)(sheng)器(qi)容(rong)量(liang)越(yue)大(da)(da),脈(mo)沖(chong)(chong)(chong)加(jia)熱(re)(re)(re)時(shi)(shi)間越(yue)短,電頻(pin)越(yue)高(gao)(gao),淬硬(ying)層越(yue)淺。沖(chong)(chong)(chong)擊(ji)感(gan)應(ying)(ying)(ying)加(jia)熱(re)(re)(re)時(shi)(shi)的(de)電頻(pin)率高(gao)(gao)達27.12MHz,此時(shi)(shi)的(de)淬硬(ying)層深(shen)度(du)(du)可(ke)(ke)達0.1mm。當發(fa)(fa)生(sheng)(sheng)器(qi)功(gong)率為10kW時(shi)(shi),可(ke)(ke)發(fa)(fa)出1MW功(gong)率的(de)脈(mo)沖(chong)(chong)(chong)。金屬表面(mian)停止(zhi)加(jia)熱(re)(re)(re)后,靠(kao)其未加(jia)熱(re)(re)(re)部分的(de)熱(re)(re)(re)傳導(dao)來(lai)冷卻(que),達到淬硬(ying)目的(de)。感(gan)應(ying)(ying)(ying)器(qi)可(ke)(ke)用圓形或(huo)扁平(ping)截面(mian)的(de)銀絲(si)或(huo)銅絲(si)。當脈(mo)沖(chong)(chong)(chong)次數在4次/s以下時(shi)(shi),無需對感(gan)應(ying)(ying)(ying)器(qi)通水冷卻(que)。

采用高頻(pin)脈沖加熱(re)表面淬火后,零件加熱(re)的時間越(yue)短,淬硬層深度(du)越(yue)淺,熱(re)處(chu)理后變形更(geng)小。

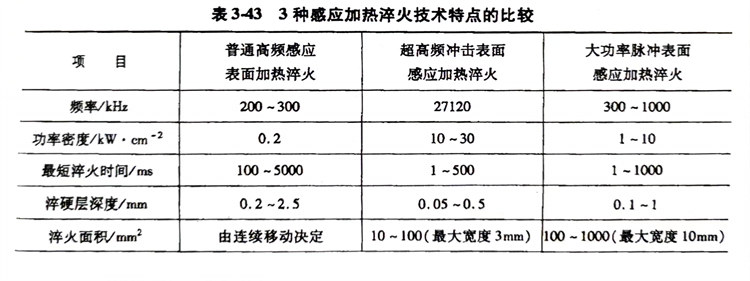

高頻感(gan)應(ying)加(jia)熱(re)向(xiang)著超(chao)高沖擊淬火(huo)(huo)和大(da)功率脈(mo)沖感(gan)應(ying)加(jia)熱(re)淬火(huo)(huo)的方向(xiang)發(fa)展。表3-43是普通(tong)高頻感(gan)應(ying)表面(mian)加(jia)熱(re)淬火(huo)(huo)、超(chao)高頻沖擊表面(mian)感(gan)應(ying)加(jia)熱(re)淬火(huo)(huo)、大(da)功率脈(mo)沖表面(mian)感(gan)應(ying)加(jia)熱(re)淬火(huo)(huo)的技術特點(dian)比較。