一、氮(dan)氣孔的形(xing)成機(ji)理

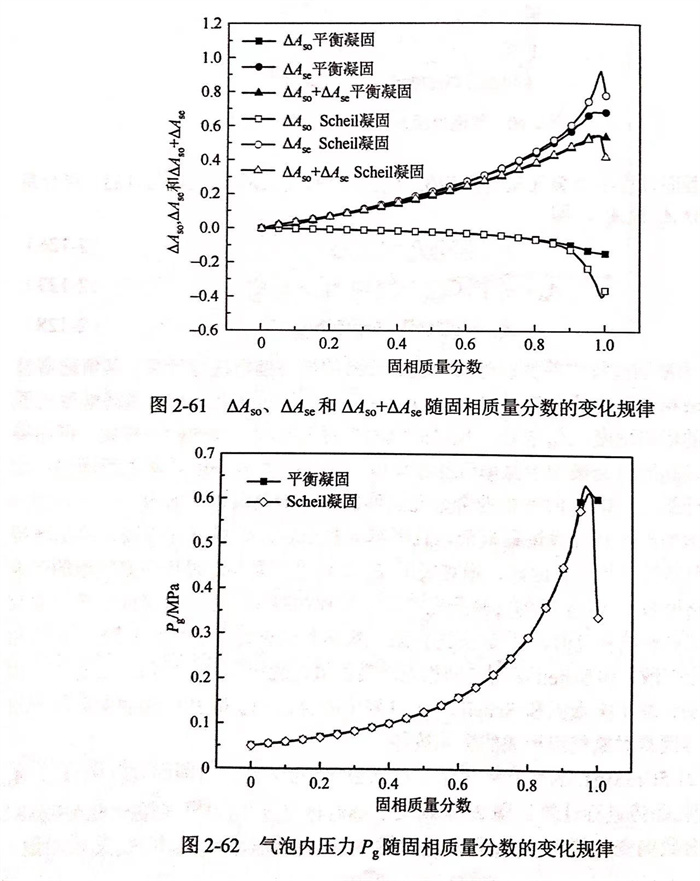

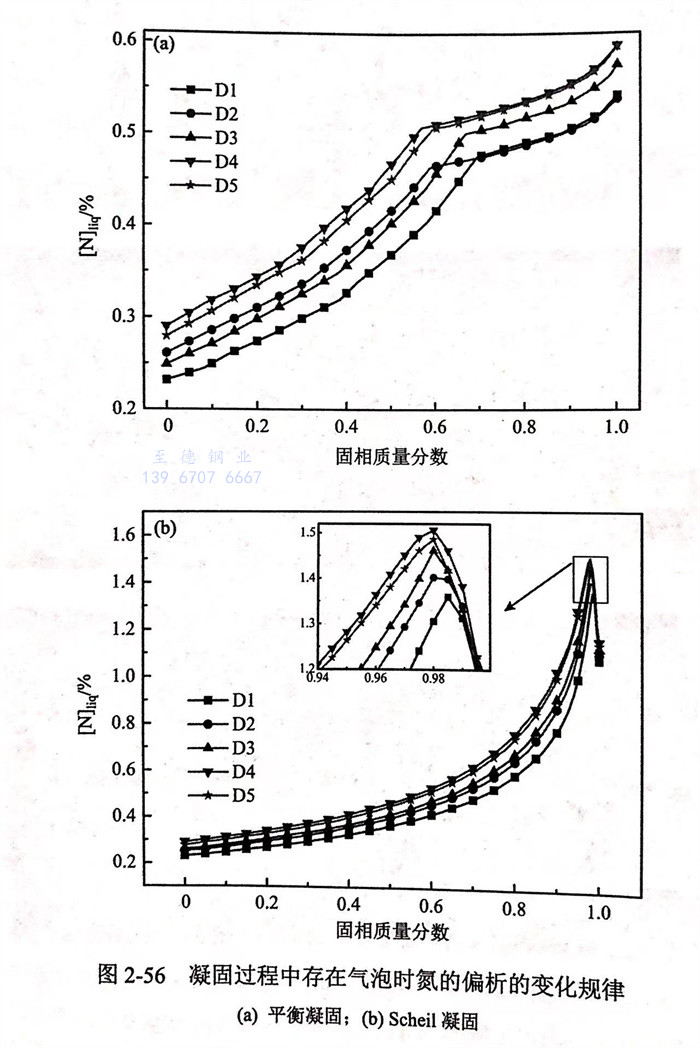

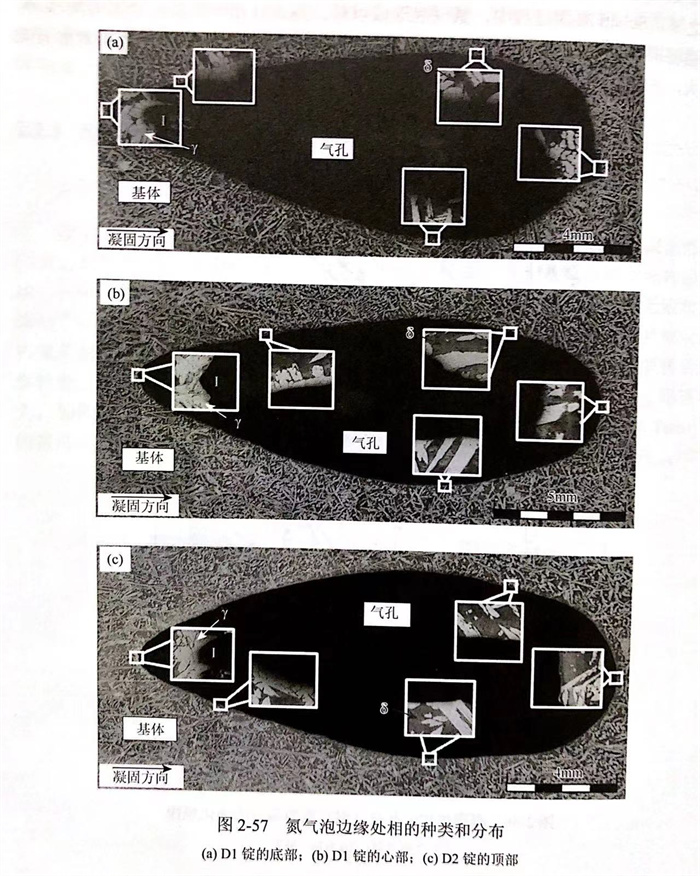

在(zai)(zai)(zai)21.5Cr5Mn1.5Ni0.25N含氮(dan)(dan)雙相(xiang)(xiang)(xiang)(xiang)鋼凝(ning)(ning)(ning)(ning)固(gu)(gu)過(guo)(guo)程(cheng)中(zhong)(zhong)(zhong)(zhong),氮(dan)(dan)氣(qi)(qi)(qi)(qi)孔形成(cheng)和(he)凝(ning)(ning)(ning)(ning)固(gu)(gu)前(qian)沿處[%N]1iq隨(sui)(sui)距離(li)變化(hua)的(de)(de)(de)(de)(de)規律(lv)如(ru)圖(tu)(tu)2-55所(suo)示(shi)(shi)。由于糊(hu)狀區(qu)內大(da)量(liang)枝晶(jing)(jing)(jing)網狀結構的(de)(de)(de)(de)(de)形成(cheng),液(ye)(ye)相(xiang)(xiang)(xiang)(xiang)的(de)(de)(de)(de)(de)對流只存在(zai)(zai)(zai)于一(yi)(yi)次(ci)枝晶(jing)(jing)(jing)尖端位置附(fu)近。且(qie)枝晶(jing)(jing)(jing)間幾乎(hu)無液(ye)(ye)相(xiang)(xiang)(xiang)(xiang)的(de)(de)(de)(de)(de)流動。因此,枝晶(jing)(jing)(jing)間殘余(yu)(yu)液(ye)(ye)相(xiang)(xiang)(xiang)(xiang)中(zhong)(zhong)(zhong)(zhong)的(de)(de)(de)(de)(de)氮(dan)(dan)傳(chuan)質主要依(yi)靠氮(dan)(dan)的(de)(de)(de)(de)(de)擴散行為(wei),且(qie)糊(hu)狀區(qu)內氮(dan)(dan)傳(chuan)質速率非常小(xiao)(xiao)。初始(shi)相(xiang)(xiang)(xiang)(xiang)貧氮(dan)(dan)鐵素(su)體(ti)(ti)相(xiang)(xiang)(xiang)(xiang)8的(de)(de)(de)(de)(de)氮(dan)(dan)溶解度(du)和(he)糊(hu)狀區(qu)的(de)(de)(de)(de)(de)氮(dan)(dan)傳(chuan)質速率較(jiao)低,導致在(zai)(zai)(zai)貧氮(dan)(dan)鐵素(su)體(ti)(ti)相(xiang)(xiang)(xiang)(xiang)枝晶(jing)(jing)(jing)附(fu)近的(de)(de)(de)(de)(de)液(ye)(ye)相(xiang)(xiang)(xiang)(xiang)中(zhong)(zhong)(zhong)(zhong)出現(xian)氮(dan)(dan)富集,且(qie)[%N]iq迅(xun)速增(zeng)(zeng)大(da),如(ru)圖(tu)(tu)2-55(a)所(suo)示(shi)(shi)。根據Yang和(he) Leel70]、Svyazhin 等、Ridolfi 和(he) Tassal的(de)(de)(de)(de)(de)報道可知,當[%N]iq的(de)(de)(de)(de)(de)最大(da)值超過(guo)(guo)氮(dan)(dan)氣(qi)(qi)(qi)(qi)泡(pao)形成(cheng)的(de)(de)(de)(de)(de)臨界氮(dan)(dan)質量(liang)分數([%N]pore)時(shi),該區(qu)域有(you)(you)氣(qi)(qi)(qi)(qi)泡(pao)形成(cheng)的(de)(de)(de)(de)(de)可能性,如(ru)圖(tu)(tu)2-55(b)所(suo)示(shi)(shi)。在(zai)(zai)(zai)后(hou)(hou)續(xu)的(de)(de)(de)(de)(de)凝(ning)(ning)(ning)(ning)固(gu)(gu)過(guo)(guo)程(cheng)中(zhong)(zhong)(zhong)(zhong),隨(sui)(sui)著(zhu)包(bao)晶(jing)(jing)(jing)反應(ying)的(de)(de)(de)(de)(de)進行,富氮(dan)(dan)奧氏體(ti)(ti)相(xiang)(xiang)(xiang)(xiang)γ以(yi)異質形核(he)的(de)(de)(de)(de)(de)方式(shi)在(zai)(zai)(zai)鐵素(su)體(ti)(ti)相(xiang)(xiang)(xiang)(xiang)8枝晶(jing)(jing)(jing)的(de)(de)(de)(de)(de)表面(mian)開(kai)始(shi)形核(he)長大(da),逐漸包(bao)裹鐵素(su)體(ti)(ti)相(xiang)(xiang)(xiang)(xiang)枝晶(jing)(jing)(jing)表面(mian),并開(kai)始(shi)捕(bu)獲殘余(yu)(yu)液(ye)(ye)相(xiang)(xiang)(xiang)(xiang)中(zhong)(zhong)(zhong)(zhong)的(de)(de)(de)(de)(de)氮(dan)(dan)氣(qi)(qi)(qi)(qi)泡(pao),對比圖(tu)(tu)2-51和(he)圖(tu)(tu)2-56可知,此時(shi)枝晶(jing)(jing)(jing)間殘余(yu)(yu)[%N]1ig的(de)(de)(de)(de)(de)增(zeng)(zeng)長速率減(jian)小(xiao)(xiao)。對平衡凝(ning)(ning)(ning)(ning)固(gu)(gu)而(er)言,殘余(yu)(yu)液(ye)(ye)相(xiang)(xiang)(xiang)(xiang)中(zhong)(zhong)(zhong)(zhong)氮(dan)(dan)氣(qi)(qi)(qi)(qi)泡(pao)形成(cheng)以(yi)后(hou)(hou),氮(dan)(dan)的(de)(de)(de)(de)(de)富集程(cheng)度(du)減(jian)弱,[%N]1iq增(zeng)(zeng)長速率的(de)(de)(de)(de)(de)減(jian)小(xiao)(xiao)程(cheng)度(du)明顯(xian);相(xiang)(xiang)(xiang)(xiang)比之下,Scheil凝(ning)(ning)(ning)(ning)固(gu)(gu)過(guo)(guo)程(cheng)中(zhong)(zhong)(zhong)(zhong),氮(dan)(dan)氣(qi)(qi)(qi)(qi)泡(pao)形成(cheng)以(yi)后(hou)(hou),殘余(yu)(yu)液(ye)(ye)相(xiang)(xiang)(xiang)(xiang)中(zhong)(zhong)(zhong)(zhong)氮(dan)(dan)富集狀態(tai)有(you)(you)所(suo)緩(huan)解,但幅度(du)很小(xiao)(xiao)。隨(sui)(sui)著(zhu)凝(ning)(ning)(ning)(ning)固(gu)(gu)界面(mian)的(de)(de)(de)(de)(de)進一(yi)(yi)步推移,被(bei)捕(bu)獲的(de)(de)(de)(de)(de)氮(dan)(dan)氣(qi)(qi)(qi)(qi)泡(pao)在(zai)(zai)(zai)奧氏體(ti)(ti)相(xiang)(xiang)(xiang)(xiang)表面(mian)開(kai)始(shi)長大(da),并沿凝(ning)(ning)(ning)(ning)固(gu)(gu)方向拉長,如(ru)圖(tu)(tu)2-55(c)所(suo)示(shi)(shi)。

氮(dan)(dan)(dan)(dan)氣(qi)(qi)(qi)孔(kong)沿徑向生長,生長方向與凝固方向一(yi)致(zhi),那么(me)氮(dan)(dan)(dan)(dan)氣(qi)(qi)(qi)孔(kong)初(chu)始形(xing)成位(wei)置靠近鑄錠(ding)邊部,且(qie)氮(dan)(dan)(dan)(dan)氣(qi)(qi)(qi)泡(pao)初(chu)始位(wei)置邊緣全由奧氏體(ti)相(xiang)γ構(gou)成(圖(tu)2-57中I區(qu)),與圖(tu)2-55描述相(xiang)符。隨(sui)著氮(dan)(dan)(dan)(dan)氣(qi)(qi)(qi)孔(kong)被拉長,鐵素體(ti)相(xiang)和奧氏體(ti)相(xiang)以體(ti)積分(fen)數比約為(wei)0.92的(de)關(guan)系交替在氮(dan)(dan)(dan)(dan)氣(qi)(qi)(qi)泡(pao)周(zhou)圍形(xing)成,直到氮(dan)(dan)(dan)(dan)氣(qi)(qi)(qi)孔(kong)閉合。凝固結束后,氮(dan)(dan)(dan)(dan)氣(qi)(qi)(qi)孔(kong)的(de)宏觀形(xing)貌類似于橢圓形(xing),與Wei等(deng)的(de)研究結果一(yi)致(zhi)

二、氮(dan)微(wei)觀偏析對氮(dan)氣孔(kong)的(de)影(ying)響(xiang)

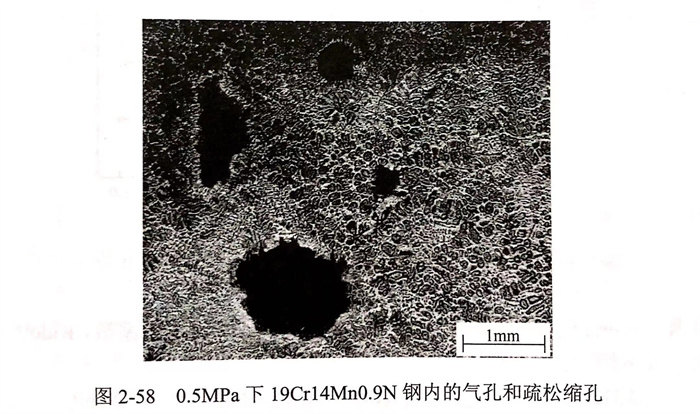

氮(dan)的(de)分配系數(shu)(shu)(shu)(shu)較(jiao)小(xiao),導致液(ye)(ye)相(xiang)向固(gu)(gu)相(xiang)轉變的(de)過(guo)(guo)程(cheng)中(zhong)(zhong)(zhong),固(gu)(gu)相(xiang)會將(jiang)多余的(de)氮(dan)轉移到殘余液(ye)(ye)相(xiang)中(zhong)(zhong)(zhong),形(xing)成(cheng)氮(dan)偏(pian)析(xi)(xi)。在(zai)(zai)氮(dan)偏(pian)析(xi)(xi)程(cheng)度(du)逐漸加(jia)重(zhong)的(de)過(guo)(guo)程(cheng)中(zhong)(zhong)(zhong),當殘余液(ye)(ye)相(xiang)中(zhong)(zhong)(zhong)氮(dan)質量分數(shu)(shu)(shu)(shu)超過(guo)(guo)其飽和度(du)時,極(ji)易(yi)形(xing)成(cheng)氮(dan)氣(qi)(qi)(qi)泡。隨(sui)著凝固(gu)(gu)的(de)進行(xing)(xing),若氣(qi)(qi)(qi)泡無(wu)法上浮而被捕獲(huo),凝固(gu)(gu)結(jie)束后就會在(zai)(zai)鑄(zhu)(zhu)錠內(nei)部形(xing)成(cheng)氣(qi)(qi)(qi)孔(kong)(kong)。因此,凝固(gu)(gu)過(guo)(guo)程(cheng)中(zhong)(zhong)(zhong)氮(dan)偏(pian)析(xi)(xi)和溶(rong)解度(du)對鑄(zhu)(zhu)錠中(zhong)(zhong)(zhong)最終氮(dan)氣(qi)(qi)(qi)孔(kong)(kong)的(de)形(xing)成(cheng)有(you)至關重(zhong)要的(de)作用。氮(dan)氣(qi)(qi)(qi)孔(kong)(kong)多數(shu)(shu)(shu)(shu)情況下(xia)與(yu)(yu)疏(shu)松縮孔(kong)(kong)共(gong)存,內(nei)壁(bi)凹凸(tu)不平呈現裂紋狀,且(qie)整個(ge)氣(qi)(qi)(qi)孔(kong)(kong)形(xing)狀不規(gui)則,如圖2-58所(suo)示。此類氣(qi)(qi)(qi)孔(kong)(kong)不僅(jin)與(yu)(yu)鋼液(ye)(ye)中(zhong)(zhong)(zhong)氣(qi)(qi)(qi)泡的(de)形(xing)成(cheng)有(you)關,還受(shou)凝固(gu)(gu)收縮等因素的(de)影響(xiang),且(qie)多數(shu)(shu)(shu)(shu)分布于鑄(zhu)(zhu)錠心(xin)部,尤其在(zai)(zai)中(zhong)(zhong)(zhong)心(xin)等軸(zhou)晶(jing)區。這主要由于中(zhong)(zhong)(zhong)心(xin)等軸(zhou)晶(jing)區內(nei)枝晶(jing)生長較(jiao)發達,容易(yi)形(xing)成(cheng)復雜的(de)網(wang)狀結(jie)構,從而將(jiang)液(ye)(ye)相(xiang)分割(ge)成(cheng)無(wu)數(shu)(shu)(shu)(shu)個(ge)獨立(li)的(de)液(ye)(ye)相(xiang)區域,當發生凝固(gu)(gu)收縮時,難以進行(xing)(xing)補縮,在(zai)(zai)形(xing)成(cheng)疏(shu)松縮孔(kong)(kong)的(de)同時,局部鋼液(ye)(ye)靜壓力降低,促使氮(dan)從殘余液(ye)(ye)相(xiang)中(zhong)(zhong)(zhong)析(xi)(xi)出,從而形(xing)成(cheng)了氮(dan)氣(qi)(qi)(qi)孔(kong)(kong)和疏(shu)松縮孔(kong)(kong)共(gong)存的(de)宏(hong)觀缺(que)陷。

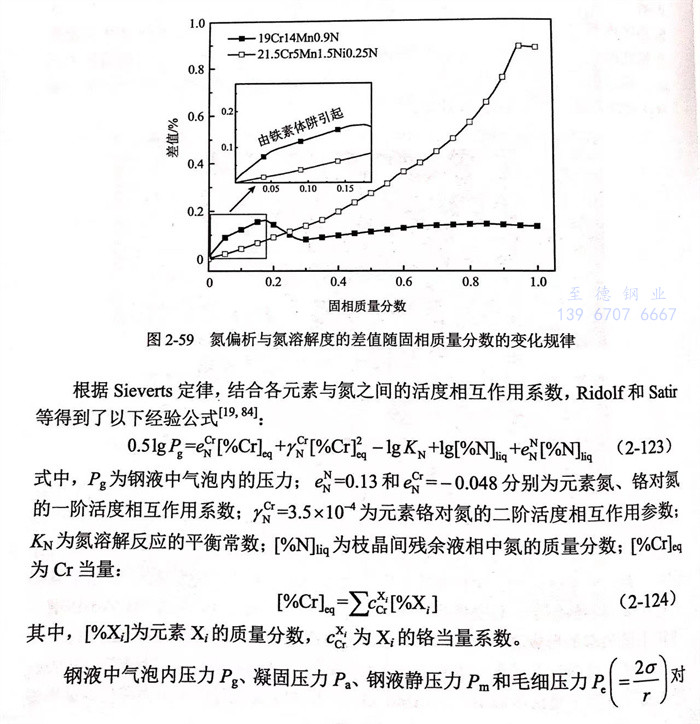

平衡凝(ning)固時(shi),19Cr14Mn0.9N含氮(dan)(dan)(dan)奧(ao)氏(shi)體(ti)(ti)(ti)(ti)不(bu)銹鋼殘余(yu)液相中氮(dan)(dan)(dan)偏析(xi)與體(ti)(ti)(ti)(ti)系(xi)氮(dan)(dan)(dan)溶解(jie)度(du)(du)的(de)差值(zhi)如圖2-59所示。凝(ning)固初(chu)期鐵素(su)體(ti)(ti)(ti)(ti)阱(ferrite trap)的(de)形(xing)成(cheng),導致氮(dan)(dan)(dan)溶解(jie)度(du)(du)的(de)降低,進而使氮(dan)(dan)(dan)偏析(xi)與體(ti)(ti)(ti)(ti)系(xi)氮(dan)(dan)(dan)溶解(jie)度(du)(du)差值(zhi)呈現出略(lve)微(wei)增大的(de)趨勢。但在(zai)(zai)后續凝(ning)固過程中,隨著(zhu)鐵素(su)體(ti)(ti)(ti)(ti)阱的(de)消失(shi)以(yi)及(ji)富氮(dan)(dan)(dan)奧(ao)氏(shi)體(ti)(ti)(ti)(ti)相的(de)不(bu)斷形(xing)成(cheng),差值(zhi)減小(xiao);在(zai)(zai)整個凝(ning)固過程中差值(zhi)始終較小(xiao),且變化幅度(du)(du)較窄。對于19Cr14Mn0.9N 含氮(dan)(dan)(dan)奧(ao)氏(shi)體(ti)(ti)(ti)(ti)不(bu)銹鋼,液相中氮(dan)(dan)(dan)氣泡(pao)的(de)形(xing)成(cheng)趨勢較小(xiao),難(nan)以(yi)在(zai)(zai)鑄錠內(nei)形(xing)成(cheng)獨(du)立內(nei)壁光滑的(de)規則氮(dan)(dan)(dan)氣孔。

此外,目前有人對(dui)奧(ao)氏(shi)(shi)體鋼(gang)(gang)凝(ning)固(gu)(gu)過程中(zhong)(zhong)(zhong)氮(dan)(dan)氣(qi)(qi)孔的(de)(de)(de)(de)形成進行了大(da)量研究(jiu),如(ru)Yang和Leel901研究(jiu)了奧(ao)氏(shi)(shi)體鋼(gang)(gang)16Cr3NixMn(x=9和11)凝(ning)固(gu)(gu)過程中(zhong)(zhong)(zhong)壓(ya)力和初(chu)始(shi)(shi)氮(dan)(dan)質量分(fen)數等(deng)(deng)因(yin)(yin)素(su)(su)(su)對(dui)氮(dan)(dan)氣(qi)(qi)孔形成的(de)(de)(de)(de)影響(xiang)(xiang)規(gui)律,并(bing)建立(li)了相應(ying)的(de)(de)(de)(de)預(yu)測模型。Ridolfi和Tassal[84]分(fen)析(xi)了氮(dan)(dan)偏(pian)析(xi)、合(he)金(jin)元素(su)(su)(su)、冷卻速率(lv)以(yi)及枝晶間(jian)距(ju)對(dui)奧(ao)氏(shi)(shi)體鋼(gang)(gang)中(zhong)(zhong)(zhong)氮(dan)(dan)氣(qi)(qi)孔的(de)(de)(de)(de)影響(xiang)(xiang)規(gui)律,并(bing)揭示了奧(ao)氏(shi)(shi)體鋼(gang)(gang)中(zhong)(zhong)(zhong)氮(dan)(dan)氣(qi)(qi)孔形成機理。然而,目前對(dui)于(yu)(yu)雙(shuang)相鋼(gang)(gang)中(zhong)(zhong)(zhong)氮(dan)(dan)氣(qi)(qi)孔形成的(de)(de)(de)(de)研究(jiu)較(jiao)少,且主要集(ji)中(zhong)(zhong)(zhong)在(zai)合(he)金(jin)元素(su)(su)(su)、鑄造方(fang)式、冷卻速率(lv)等(deng)(deng)因(yin)(yin)素(su)(su)(su)對(dui)氮(dan)(dan)氣(qi)(qi)孔影響(xiang)(xiang)規(gui)律的(de)(de)(de)(de)研究(jiu),鮮(xian)有對(dui)雙(shuang)相鋼(gang)(gang)中(zhong)(zhong)(zhong)氮(dan)(dan)氣(qi)(qi)孔形成機理的(de)(de)(de)(de)報(bao)道(dao)。以(yi)21.5Cr5Mn1.5Ni0.25N含氮(dan)(dan)雙(shuang)相鋼(gang)(gang)為(wei)例,氮(dan)(dan)偏(pian)析(xi)與(yu)溶(rong)解度的(de)(de)(de)(de)差值(zhi)在(zai)整個凝(ning)固(gu)(gu)過程中(zhong)(zhong)(zhong)的(de)(de)(de)(de)變化趨勢(shi)(shi),如(ru)圖(tu)2-59所示。隨著凝(ning)固(gu)(gu)的(de)(de)(de)(de)進行,氮(dan)(dan)偏(pian)析(xi)始(shi)(shi)終大(da)于(yu)(yu)氮(dan)(dan)溶(rong)解度,且差值(zhi)呈現(xian)出快速增大(da)的(de)(de)(de)(de)趨勢(shi)(shi)。因(yin)(yin)此,在(zai)21.5Cr5Mn1.5Ni0.25N 含氮(dan)(dan)雙(shuang)相鋼(gang)(gang)凝(ning)固(gu)(gu)過程中(zhong)(zhong)(zhong),氮(dan)(dan)偏(pian)析(xi)嚴重,殘(can)余液(ye)相內氮(dan)(dan)氣(qi)(qi)泡形成趨勢(shi)(shi)較(jiao)大(da),明顯高(gao)于(yu)(yu)19Cr14Mn0.9N含氮(dan)(dan)奧(ao)氏(shi)(shi)體不銹鋼(gang)(gang)。

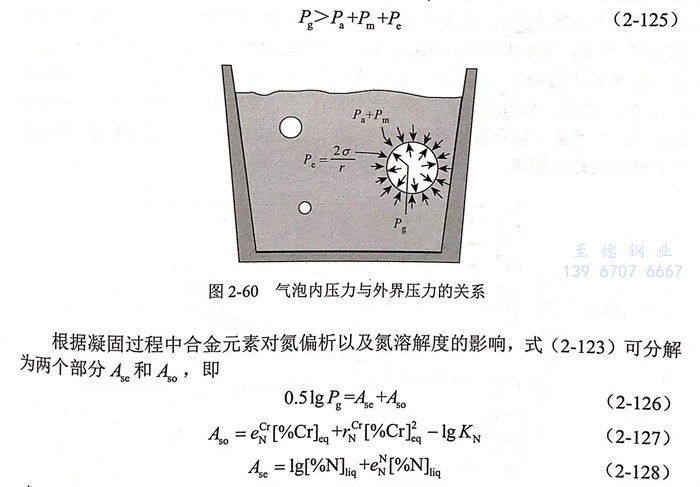

氮氣(qi)泡(pao)形成和長大具有重(zhong)要的作用(圖(tu)2-60).其中,σ為(wei)氣(qi)液(ye)界(jie)面(mian)的表面(mian)張(zhang)力(li),r為(wei)氣(qi)泡(pao)半(ban)徑。結合經(jing)典形核理(li)論,氮氣(qi)泡(pao)在(zai)(zai)鋼液(ye)中穩定(ding)存在(zai)(zai)的必要條(tiao)件為(wei)氣(qi)泡(pao)內(nei)壓力(li)大于作用于氣(qi)泡(pao)的所有壓力(li)之和,即

式中(zhong),Aso由(you)凝固過程中(zhong)除氮(dan)以外其他合(he)(he)金(jin)元素(su)的(de)微(wei)觀偏(pian)(pian)(pian)(pian)析(xi)進行計算,其值隨著(zhu)枝(zhi)晶(jing)間(jian)(jian)殘余(yu)(yu)液(ye)相(xiang)中(zhong)氮(dan)溶(rong)解(jie)(jie)度(du)的(de)增(zeng)加而(er)減小,表征了(le)枝(zhi)晶(jing)間(jian)(jian)殘余(yu)(yu)液(ye)相(xiang)中(zhong)氮(dan)溶(rong)解(jie)(jie)度(du)對氮(dan)氣泡形(xing)成的(de)影響程度(du);Ase表征了(le)枝(zhi)晶(jing)間(jian)(jian)氮(dan)偏(pian)(pian)(pian)(pian)析(xi)對氮(dan)氣泡形(xing)成的(de)影響程度(du),可由(you)凝固過程中(zhong)枝(zhi)晶(jing)間(jian)(jian)殘余(yu)(yu)液(ye)相(xiang)中(zhong)氮(dan)偏(pian)(pian)(pian)(pian)析(xi)計算獲得(de),其值隨著(zhu)氮(dan)偏(pian)(pian)(pian)(pian)析(xi)的(de)增(zeng)大而(er)增(zeng)大。此外,用于(yu)計算Aso和(he)Ase時所需的(de)合(he)(he)金(jin)元素(su)偏(pian)(pian)(pian)(pian)析(xi)均由(you)鋼凝固相(xiang)變所致。

氮氣(qi)泡(pao)的形(xing)核(he)和(he)長(chang)大(da)過(guo)程(cheng)(cheng)復(fu)雜,且影(ying)響(xiang)因(yin)素(su)眾多(duo),包(bao)括(kuo)凝(ning)固(gu)(gu)(gu)(gu)收縮、冶煉環境以及坩堝材質(zhi)等。因(yin)此,很難采用Pg值精確預測凝(ning)固(gu)(gu)(gu)(gu)過(guo)程(cheng)(cheng)中(zhong)氮氣(qi)泡(pao)的形(xing)成和(he)長(chang)大(da)。然(ran)而基于(yu)Yang等的實(shi)驗研究(jiu)[70,77],在評估凝(ning)固(gu)(gu)(gu)(gu)壓力、合金成分等因(yin)素(su)對氮氣(qi)泡(pao)形(xing)成的影(ying)響(xiang)程(cheng)(cheng)度時,Pg起關鍵(jian)作用。實(shi)際凝(ning)固(gu)(gu)(gu)(gu)過(guo)程(cheng)(cheng)介于(yu)平衡凝(ning)固(gu)(gu)(gu)(gu)(固(gu)(gu)(gu)(gu)/液相中(zhong)溶(rong)質(zhi)完全(quan)擴散)和(he)Scheil凝(ning)固(gu)(gu)(gu)(gu)(固(gu)(gu)(gu)(gu)相無溶(rong)質(zhi)擴散,液相中(zhong)完全(quan)擴散)之間70].因(yin)此,可分別計算平衡凝(ning)固(gu)(gu)(gu)(gu)和(he)Scheil凝(ning)固(gu)(gu)(gu)(gu)過(guo)程(cheng)(cheng)中(zhong)的Aso、Ase和(he)Pg,闡明實(shi)際凝(ning)固(gu)(gu)(gu)(gu)過(guo)程(cheng)(cheng)中(zhong)壓力等因(yin)素(su)對氮氣(qi)泡(pao)形(xing)成的影(ying)響(xiang)規律。

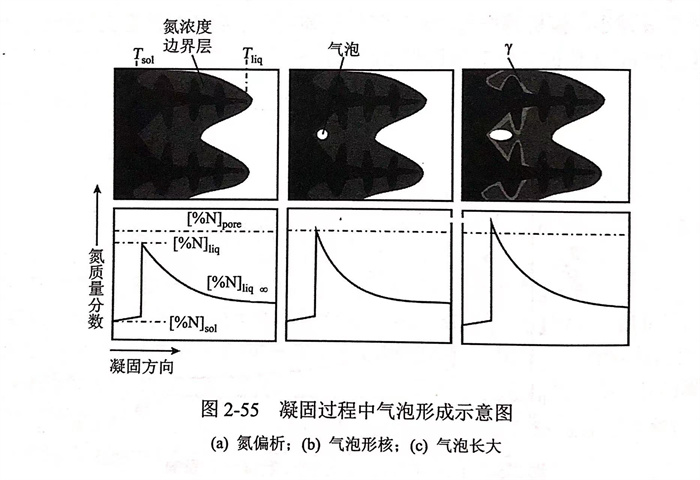

現以21.5Cr5Mn1.5Ni0.25N含(han)氮雙相鋼D1鑄(zhu)錠(ding)為例,對凝固(gu)(gu)過程(cheng)中(zhong)Aso、Ase和(he)P8的(de)(de)變化趨勢進(jin)行計算。圖(tu)2-61描(miao)述了ΔAso(=Asa-Aso,0)和(he)AAse(=Ase-Ase,o)隨固(gu)(gu)相質量分數(shu)的(de)(de)變化趨勢(Aso,0和(he)Asc,0分別為D1鑄(zhu)錠(ding)凝固(gu)(gu)時Aso和(he)Ase的(de)(de)初始值(zhi))。

在(zai)平衡(heng)凝(ning)(ning)固(gu)(gu)和(he)(he)(he)Scheil凝(ning)(ning)固(gu)(gu)過程中(zhong)(zhong),ΔAso的(de)(de)(de)(de)(de)最小值分(fen)別為-0.145和(he)(he)(he)-0.397,與此相對(dui)應的(de)(de)(de)(de)(de)ΔAse值最大(da)(da),分(fen)別為0.68和(he)(he)(he)0.92.在(zai)整個(ge)凝(ning)(ning)固(gu)(gu)過程中(zhong)(zhong),由于(yu)ΔAse與ΔAso之和(he)(he)(he)始(shi)終大(da)(da)于(yu)零,因而枝晶間殘余液相中(zhong)(zhong)氮(dan)偏析對(dui)D1 鑄錠凝(ning)(ning)固(gu)(gu)過程中(zhong)(zhong)氮(dan)氣泡形(xing)(xing)成(cheng)的(de)(de)(de)(de)(de)影響(xiang)大(da)(da)于(yu)氮(dan)溶解度,起主導作用。此外,在(zai)整個(ge)凝(ning)(ning)固(gu)(gu)過程中(zhong)(zhong),P8變化趨勢如圖2-62所示(shi),其變化規律與Young等(deng)。的(de)(de)(de)(de)(de)研究結(jie)果一致,Pg的(de)(de)(de)(de)(de)最大(da)(da)值Pg與Ase+Aso的(de)(de)(de)(de)(de)最大(da)(da)值相對(dui)應,且在(zai)平衡(heng)凝(ning)(ning)固(gu)(gu)和(he)(he)(he) Scheil 凝(ning)(ning)固(gu)(gu)過程中(zhong)(zhong)分(fen)別為0.63MPa和(he)(he)(he)0.62MPa.此外,可通(tong)過對(dui)比不(bu)同(tong)鑄錠中(zhong)(zhong)的(de)(de)(de)(de)(de)探討凝(ning)(ning)固(gu)(gu)壓(ya)力(li)、初始(shi)氮(dan)質量(liang)分(fen)數以及(ji)合金元(yuan)素(su)(鉻和(he)(he)(he)錳)等(deng)對(dui)液相中(zhong)(zhong)氮(dan)氣泡形(xing)(xing)成(cheng)的(de)(de)(de)(de)(de)影響(xiang),進而明晰各因素(su)對(dui)氮(dan)氣孔形(xing)(xing)成(cheng)的(de)(de)(de)(de)(de)影響(xiang)規律。