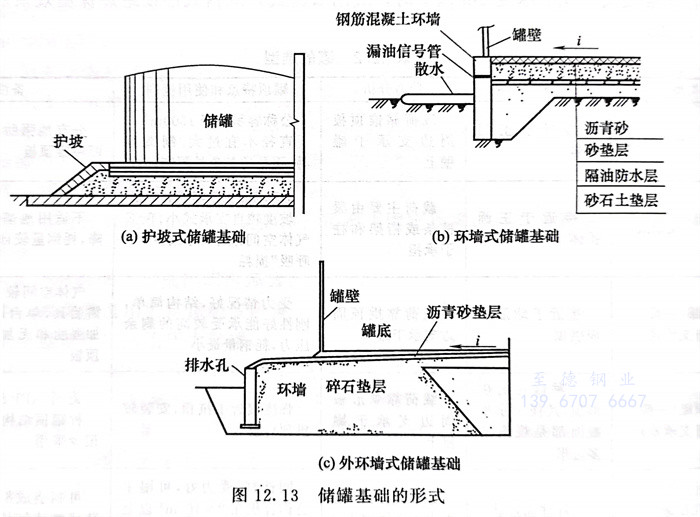

1. 罐基礎的(de)形式

罐基礎通常有護坡式、環墻式、外環墻式三種,見圖12.13。當地基土層能滿足承載力設計值和沉降差的要求且場地不受限制時,宜采用護坡式或外環墻式基礎;當地基土層不能滿足承載力設計值要求但沉降量不超過允許值時,可采用環墻式或外環墻式基礎;當地基土層為軟土層時,宜對地基處理后再采用外環墻式基礎;當場地受限時,可采用環墻式基礎。儲罐基礎設計與施工的規范有:SH/T 3083《石油化工鋼儲罐地基處理技術規范》和SH 3086《石油化工鋼儲罐地基與基礎設計規范》。

儲(chu)(chu)罐(guan)(guan)(guan)(guan)基(ji)礎設計和施工質量直接影響(xiang)到(dao)儲(chu)(chu)罐(guan)(guan)(guan)(guan)的安全運行。從大(da)(da)(da)量儲(chu)(chu)罐(guan)(guan)(guan)(guan)事故發生(sheng)的原(yuan)因分(fen)析(xi),大(da)(da)(da)致(zhi)可歸納為(wei):由于操作(zuo)失(shi)誤或(huo)安全附(fu)件失(shi)靈引(yin)起的罐(guan)(guan)(guan)(guan)體失(shi)穩;罐(guan)(guan)(guan)(guan)壁(bi)(bi)焊縫缺陷(xian)(xian)引(yin)起的儲(chu)(chu)液泄漏;罐(guan)(guan)(guan)(guan)底的脆性破裂;臺風或(huo)地震(zhen)引(yin)起的罐(guan)(guan)(guan)(guan)體破壞和儲(chu)(chu)罐(guan)(guan)(guan)(guan)基(ji)礎沉(chen)(chen)陷(xian)(xian)引(yin)起的破壞。現僅就儲(chu)(chu)罐(guan)(guan)(guan)(guan)基(ji)礎沉(chen)(chen)陷(xian)(xian)對儲(chu)(chu)罐(guan)(guan)(guan)(guan)產生(sheng)的影響(xiang)、儲(chu)(chu)罐(guan)(guan)(guan)(guan)基(ji)礎的形(xing)(xing)式以及儲(chu)(chu)罐(guan)(guan)(guan)(guan)對基(ji)礎的要求進行分(fen)析(xi)。儲(chu)(chu)罐(guan)(guan)(guan)(guan)基(ji)礎的均(jun)勻沉(chen)(chen)陷(xian)(xian)一般不會(hui)給儲(chu)(chu)罐(guan)(guan)(guan)(guan)造(zao)成(cheng)(cheng)大(da)(da)(da)的危害,因為(wei)儲(chu)(chu)罐(guan)(guan)(guan)(guan)是由薄壁(bi)(bi)鋼板焊接成(cheng)(cheng)的立式圓筒形(xing)(xing)結構,具(ju)有柔性大(da)(da)(da)、剛性小的特(te)點,對基(ji)礎的沉(chen)(chen)陷(xian)(xian)變形(xing)(xing)具(ju)有一定(ding)的適應(ying)性。只有沉(chen)(chen)陷(xian)(xian)到(dao)一定(ding)程(cheng)度時,如(ru)儲(chu)(chu)罐(guan)(guan)(guan)(guan)出(chu)口管(guan)與罐(guan)(guan)(guan)(guan)壁(bi)(bi)相接處(chu)產生(sheng)附(fu)加應(ying)力很大(da)(da)(da),才會(hui)造(zao)成(cheng)(cheng)破壞。

2. 罐基礎(chu)的沉降

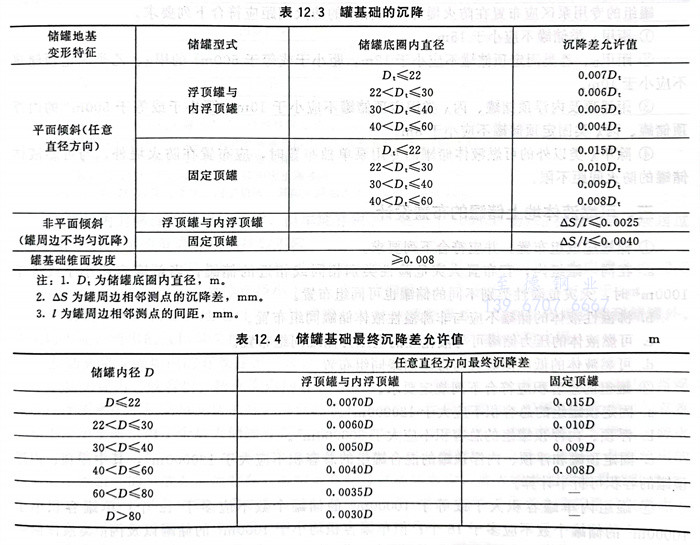

①. 罐基礎的沉降見表(biao)12.3。

②. 在(zai)SH/T 3528-2014《石油化工鋼制儲(chu)罐(guan)(guan)地基(ji)與基(ji)礎施工及驗(yan)收規(gui)范》內(nei)也規(gui)定了儲(chu)罐(guan)(guan)的沉降允許值(zhi),見表12.4。