管殼式換(huan)(huan)熱器(qi)又稱列管式換(huan)(huan)熱器(qi)。是以封閉在殼體(ti)中管束的(de)壁面作為傳熱面的(de)間壁式換(huan)(huan)熱器(qi)。這種(zhong)換(huan)(huan)熱器(qi)結(jie)構(gou)較簡(jian)單,操作可(ke)靠,可(ke)用各(ge)種(zhong)結(jie)構(gou)材(cai)料(主要是金(jin)屬材(cai)料)制造(zao),能在高溫(wen)、高壓(ya)下使用,是目(mu)前應用最廣的(de)類型(xing)。

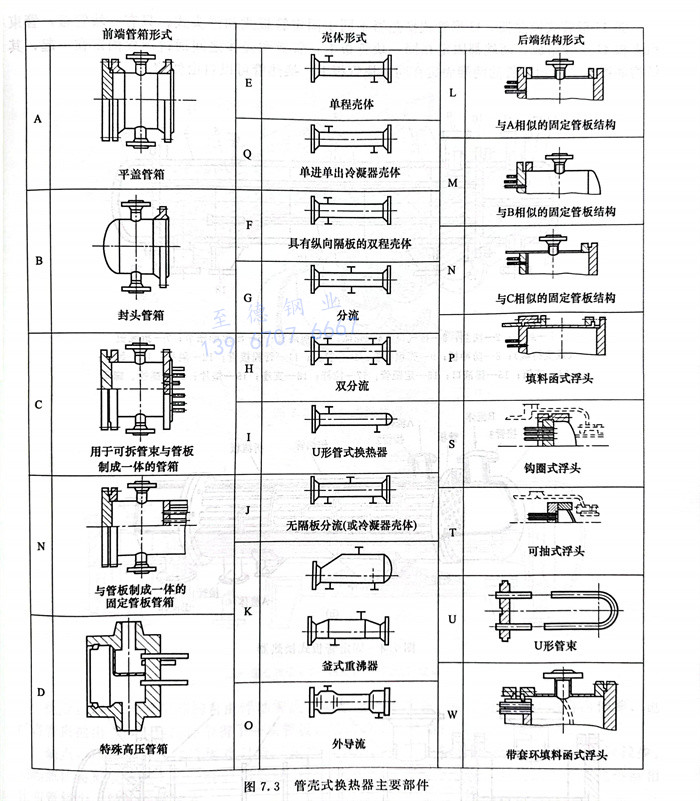

管(guan)(guan)(guan)殼式換(huan)熱(re)(re)(re)器(qi)(qi)(qi)(qi)由殼體(ti)(ti)(ti)、傳熱(re)(re)(re)管(guan)(guan)(guan)束(shu)、管(guan)(guan)(guan)板(ban)(ban)、折流(liu)板(ban)(ban)(擋板(ban)(ban))和(he)管(guan)(guan)(guan)箱等部(bu)件組成。殼體(ti)(ti)(ti)多(duo)為(wei)圓(yuan)筒形,內(nei)部(bu)裝有管(guan)(guan)(guan)束(shu),管(guan)(guan)(guan)束(shu)兩(liang)端固(gu)定在管(guan)(guan)(guan)板(ban)(ban)上,而管(guan)(guan)(guan)板(ban)(ban)又與外殼連接在一起。進行換(huan)熱(re)(re)(re)的冷、熱(re)(re)(re)兩(liang)種流(liu)體(ti)(ti)(ti),一種在管(guan)(guan)(guan)內(nei)流(liu)動,稱為(wei)管(guan)(guan)(guan)程(cheng)(cheng)流(liu)體(ti)(ti)(ti);另一種在管(guan)(guan)(guan)外流(liu)動,稱為(wei)殼程(cheng)(cheng)流(liu)體(ti)(ti)(ti)。為(wei)提(ti)(ti)高管(guan)(guan)(guan)外流(liu)體(ti)(ti)(ti)的傳熱(re)(re)(re)膜系數,通常(chang)在殼體(ti)(ti)(ti)內(nei)安裝若(ruo)干擋板(ban)(ban)。擋板(ban)(ban)可提(ti)(ti)高殼程(cheng)(cheng)流(liu)體(ti)(ti)(ti)速度,迫使流(liu)體(ti)(ti)(ti)按規定路程(cheng)(cheng)多(duo)次橫向(xiang)通過管(guan)(guan)(guan)束(shu),增強(qiang)流(liu)體(ti)(ti)(ti)湍流(liu)程(cheng)(cheng)度。圖(tu)7.2(a)為(wei)最簡單的單殼程(cheng)(cheng)單管(guan)(guan)(guan)程(cheng)(cheng)換(huan)熱(re)(re)(re)器(qi)(qi)(qi)(qi)。管(guan)(guan)(guan)殼式換(huan)熱(re)(re)(re)器(qi)(qi)(qi)(qi)按結構特(te)點分為(wei)固(gu)定管(guan)(guan)(guan)板(ban)(ban)式換(huan)熱(re)(re)(re)器(qi)(qi)(qi)(qi)、浮頭(tou)式換(huan)熱(re)(re)(re)器(qi)(qi)(qi)(qi)、U形管(guan)(guan)(guan)式換(huan)熱(re)(re)(re)器(qi)(qi)(qi)(qi)、填(tian)函式換(huan)熱(re)(re)(re)器(qi)(qi)(qi)(qi)、雙重管(guan)(guan)(guan)式換(huan)熱(re)(re)(re)器(qi)(qi)(qi)(qi)和(he)雙管(guan)(guan)(guan)板(ban)(ban)換(huan)熱(re)(re)(re)器(qi)(qi)(qi)(qi)等,前3種應用比較普遍。

管(guan)(guan)(guan)(guan)殼(ke)(ke)式換(huan)熱(re)(re)(re)(re)(re)器(qi)(qi)管(guan)(guan)(guan)(guan)束(shu)由許多(duo)管(guan)(guan)(guan)(guan)子組成(cheng)(cheng),管(guan)(guan)(guan)(guan)束(shu)構(gou)成(cheng)(cheng)換(huan)熱(re)(re)(re)(re)(re)器(qi)(qi)的(de)傳熱(re)(re)(re)(re)(re)面(mian)。為了增加流(liu)(liu)體(ti)(ti)(ti)在(zai)管(guan)(guan)(guan)(guan)外(wai)空間的(de)流(liu)(liu)速,以提高換(huan)熱(re)(re)(re)(re)(re)器(qi)(qi)殼(ke)(ke)程(cheng)的(de)傳熱(re)(re)(re)(re)(re)膜系數(shu),改善(shan)換(huan)熱(re)(re)(re)(re)(re)器(qi)(qi)的(de)傳熱(re)(re)(re)(re)(re)情況,在(zai)筒體(ti)(ti)(ti)內間隔安(an)裝(zhuang)了許多(duo)折流(liu)(liu)擋(dang)板。換(huan)熱(re)(re)(re)(re)(re)器(qi)(qi)的(de)殼(ke)(ke)體(ti)(ti)(ti)和兩側管(guan)(guan)(guan)(guan)箱(xiang)(xiang)(xiang)上(shang)(對(dui)于偶數(shu)管(guan)(guan)(guan)(guan)程(cheng)的(de),則在(zai)一(yi)(yi)(yi)側)開(kai)有流(liu)(liu)體(ti)(ti)(ti)的(de)進(jin)(jin)出口,有時(shi)還(huan)在(zai)其上(shang)裝(zhuang)設(she)檢查孔(kong),為安(an)置(zhi)儀表(biao)用的(de)接口管(guan)(guan)(guan)(guan)、排液孔(kong)和排氣孔(kong)等。在(zai)換(huan)熱(re)(re)(re)(re)(re)器(qi)(qi)中,一(yi)(yi)(yi)種流(liu)(liu)體(ti)(ti)(ti)從一(yi)(yi)(yi)側管(guan)(guan)(guan)(guan)箱(xiang)(xiang)(xiang)(成(cheng)(cheng)為前管(guan)(guan)(guan)(guan)箱(xiang)(xiang)(xiang))流(liu)(liu)進(jin)(jin)管(guan)(guan)(guan)(guan)子里,經另(ling)一(yi)(yi)(yi)側管(guan)(guan)(guan)(guan)箱(xiang)(xiang)(xiang)(成(cheng)(cheng)為后管(guan)(guan)(guan)(guan)箱(xiang)(xiang)(xiang))流(liu)(liu)出(對(dui)奇數(shu)單管(guan)(guan)(guan)(guan)程(cheng)換(huan)熱(re)(re)(re)(re)(re)器(qi)(qi)),或繞過管(guan)(guan)(guan)(guan)箱(xiang)(xiang)(xiang),流(liu)(liu)回進(jin)(jin)口側前管(guan)(guan)(guan)(guan)箱(xiang)(xiang)(xiang)流(liu)(liu)出(對(dui)偶數(shu)管(guan)(guan)(guan)(guan)程(cheng)換(huan)熱(re)(re)(re)(re)(re)器(qi)(qi)),流(liu)(liu)體(ti)(ti)(ti)每(mei)(mei)通過管(guan)(guan)(guan)(guan)束(shu)一(yi)(yi)(yi)次(ci)稱為一(yi)(yi)(yi)個管(guan)(guan)(guan)(guan)程(cheng)。另(ling)一(yi)(yi)(yi)種流(liu)(liu)體(ti)(ti)(ti)從筒體(ti)(ti)(ti)上(shang)的(de)連接管(guan)(guan)(guan)(guan)進(jin)(jin)出換(huan)熱(re)(re)(re)(re)(re)器(qi)(qi)管(guan)(guan)(guan)(guan)體(ti)(ti)(ti),流(liu)(liu)經管(guan)(guan)(guan)(guan)束(shu)外(wai),每(mei)(mei)通過殼(ke)(ke)體(ti)(ti)(ti)一(yi)(yi)(yi)次(ci)稱為一(yi)(yi)(yi)個殼(ke)(ke)程(cheng)。圖(tu)(tu)7.2(c)所示為二管(guan)(guan)(guan)(guan)程(cheng)、單殼(ke)(ke)程(cheng),工程(cheng)上(shang)稱為1-2型(xing)換(huan)熱(re)(re)(re)(re)(re)器(qi)(qi)(此處1表(biao)示殼(ke)(ke)程(cheng)數(shu),2表(biao)示管(guan)(guan)(guan)(guan)程(cheng)數(shu))。同(tong)樣(yang),在(zai)換(huan)熱(re)(re)(re)(re)(re)器(qi)(qi)筒體(ti)(ti)(ti)內加縱向擋(dang)板也能(neng)得到多(duo)殼(ke)(ke)程(cheng)結構(gou),見圖(tu)(tu)7.2(b)。

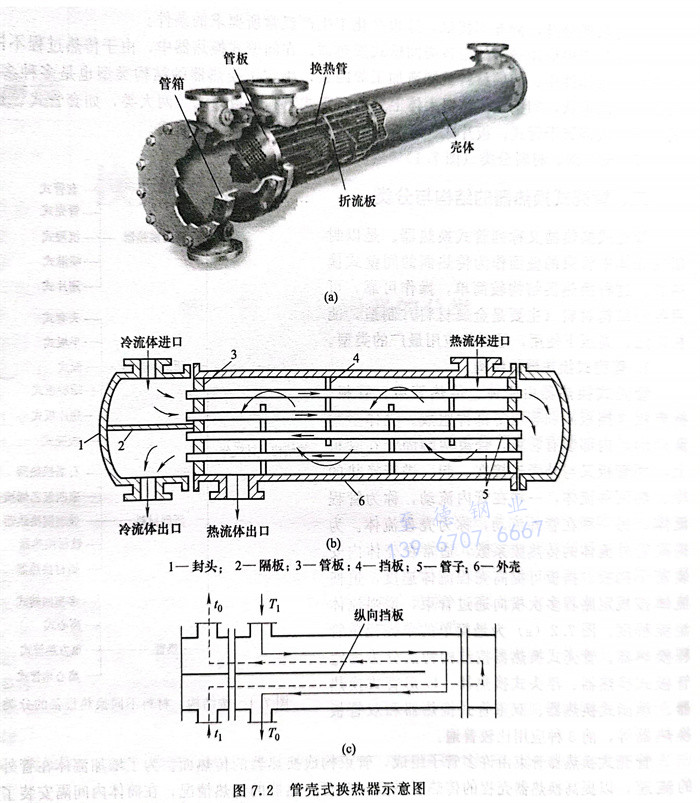

按GB151的規定,管(guan)殼式換(huan)熱器主要部(bu)件如圖7.3所示。