1. 不銹鋼焊接(jie)鋼管用途(tu)不同而(er)分(fen)為如下標準。

2. 板焊管的選用。鋼板焊制不銹鋼管(板焊管)國內尚無標準,板焊管制造標準可暫參照ASTM A671《常溫和低溫用電熔焊鋼管》、ASTM A672《中溫和高壓用電熔焊鋼管》和ASTMA691《高溫和高壓用碳素鋼和合金鋼電熔焊鋼管》,或按照GB50235《工業金屬管道工程施工及驗收規范》和GB 50316《工業金屬管道設計規范》附錄的現場制造鋼板卷管的規定要求制造。或參照GB/T 9711.1《石油天然氣工業輸送鋼管 交貨技術條件第1部分:A級鋼管》。

3. 連(lian)續(xu)爐焊(han)(鍛焊(han))鋼(gang)(gang)管(guan)(guan)(guan)(guan)、電(dian)阻焊(han)鋼(gang)(gang)管(guan)(guan)(guan)(guan)和電(dian)弧(hu)焊(han)鋼(gang)(gang)管(guan)(guan)(guan)(guan)的(de)選用(yong)。常用(yong)的(de)焊(han)接鋼(gang)(gang)管(guan)(guan)(guan)(guan)根據(ju)其(qi)生產(chan)時采(cai)用(yong)的(de)焊(han)接工藝不同(tong)可以(yi)分為:連(lian)續(xu)爐焊(han)(鍛焊(han))鋼(gang)(gang)管(guan)(guan)(guan)(guan)、電(dian)阻焊(han)鋼(gang)(gang)管(guan)(guan)(guan)(guan)和電(dian)弧(hu)焊(han)鋼(gang)(gang)管(guan)(guan)(guan)(guan)三(san)種。

①. 連續爐焊(鍛焊)鋼管(guan):連續爐焊(鍛焊)鋼管(guan)是在(zai)加(jia)熱爐內對(dui)鋼帶進行(xing)加(jia)熱,然后(hou)對(dui)已(yi)成(cheng)型的邊緣采(cai)用(yong)機械加(jia)壓方(fang)法使其焊接在(zai)一(yi)起而形成(cheng)的具有一(yi)條直縫的鋼管(guan)。特點:生產效率高,生產成(cheng)本低;但焊縫質量(liang)差,綜合機械性能差。材料(liao)牌號(hao):Q195A、Q215A、Q235A等3種。用(yong)途:適于(yu)設計溫度為0~100℃、設計壓力不超過0.6MPa的水和壓縮空氣(qi)系統(tong)。標準(zhun):GB/T 3091《流體輸送用(yong)焊接鋼管(guan)》。

②. 電(dian)阻焊(han)(han)鋼(gang)管(electric-resistance welded steel pipe):電(dian)阻焊(han)(han)鋼(gang)管是(shi)通(tong)過電(dian)阻焊(han)(han)或電(dian)感應焊(han)(han)焊(han)(han)接(jie)(jie)(jie)方法生產(chan)的,帶有一條直(zhi)焊(han)(han)縫的鋼(gang)管。特點:生產(chan)效率高,自動化程度高,焊(han)(han)后的變形(xing)和(he)殘余應力較(jiao)小。設(she)備投(tou)資高,對焊(han)(han)接(jie)(jie)(jie)接(jie)(jie)(jie)頭(tou)(tou)(tou)的質(zhi)量要(yao)求也比較(jiao)高。由于接(jie)(jie)(jie)頭(tou)(tou)(tou)處難免有雜質(zhi)存在,所(suo)以(yi)接(jie)(jie)(jie)頭(tou)(tou)(tou)塑性和(he)沖(chong)擊韌性較(jiao)低。標(biao)準:SY/T 5038《普通(tong)流(liu)體(ti)(ti)輸送用(yong)(yong)螺(luo)旋縫高頻焊(han)(han)鋼(gang)管》,材料牌(pai)號:Q195A、Q215A、Q235A等(deng)3種,用(yong)(yong)途(tu):適用(yong)(yong)于設(she)計溫度≤200℃的水、煤氣、空(kong)氣、采暖蒸汽等(deng)。標(biao)準:GB/T 9711.1《石油(you)天然氣工(gong)業(ye)輸送鋼(gang)管交貨技術條件》,材料牌(pai)號:L175、L210,L245,L290,L320,L360,L450等(deng)15種,用(yong)(yong)途(tu):石油(you)天然氣工(gong)業(ye)中(zhong)可(ke)燃(ran)流(liu)體(ti)(ti)和(he)非可(ke)燃(ran)流(liu)體(ti)(ti)(中(zhong)、低壓(ya))。

③. 電(dian)弧(hu)焊(han)(han)(han)鋼(gang)管(guan)(electric-arc-welded steel pipe):電(dian)弧(hu)焊(han)(han)(han)鋼(gang)管(guan)是通過(guo)電(dian)弧(hu)焊(han)(han)(han)焊(han)(han)(han)接(jie)(jie)方法生(sheng)產的(de)鋼(gang)管(guan)。特(te)點:接(jie)(jie)頭(tou)達到完全(quan)的(de)冶金結合,接(jie)(jie)頭(tou)的(de)機械(xie)性能(neng)(neng)能(neng)(neng)夠完全(quan)達到或(huo)達到母(mu)材的(de)機械(xie)性能(neng)(neng)。在經過(guo)適當的(de)熱處理和(he)無損檢查之后,電(dian)弧(hu)焊(han)(han)(han)直縫(feng)(feng)鋼(gang)管(guan)的(de)使(shi)用(yong)(yong)(yong)條件可達到無縫(feng)(feng)鋼(gang)管(guan)的(de)使(shi)用(yong)(yong)(yong)條件而(er)取代之。螺旋縫(feng)(feng)鋼(gang)管(guan)材料牌號:Q195、Q215、Q235等3種,用(yong)(yong)(yong)途:適用(yong)(yong)(yong)于(yu)(yu)(yu)設計(ji)(ji)溫度≤200℃的(de)水(shui)、煤氣、空氣、采暖蒸汽(qi)等;標準(zhun)(zhun):SY/T 5037《普通流體(ti)輸(shu)送(song)用(yong)(yong)(yong)螺旋縫(feng)(feng)埋弧(hu)焊(han)(han)(han)鋼(gang)管(guan)》,直縫(feng)(feng)鋼(gang)管(guan)材料牌號:1Cr18Ni9、0Cr19Ni9、00Cr19Ni11、0Cr18Ni10Ti、0Cr17Ni12Mo2、00Cr17Ni14Mo2共12種(新(xin)版標準(zhun)(zhun)更新(xin)為新(xin)的(de)牌號),用(yong)(yong)(yong)途:設計(ji)(ji)壓力小(xiao)于(yu)(yu)(yu)5.0MPa,焊(han)(han)(han)縫(feng)(feng)系數小(xiao)于(yu)(yu)(yu)1.0時,不宜用(yong)(yong)(yong)于(yu)(yu)(yu)極(ji)度或(huo)高度危害介質;電(dian)弧(hu)焊(han)(han)(han)鋼(gang)管(guan)標準(zhun)(zhun)還有:GB12771《流體(ti)輸(shu)送(song)用(yong)(yong)(yong)不銹鋼(gang)焊(han)(han)(han)接(jie)(jie)鋼(gang)管(guan)》,HG/T 50237.1~4《奧氏體(ti)不銹鋼(gang)焊(han)(han)(han)接(jie)(jie)鋼(gang)管(guan)》。

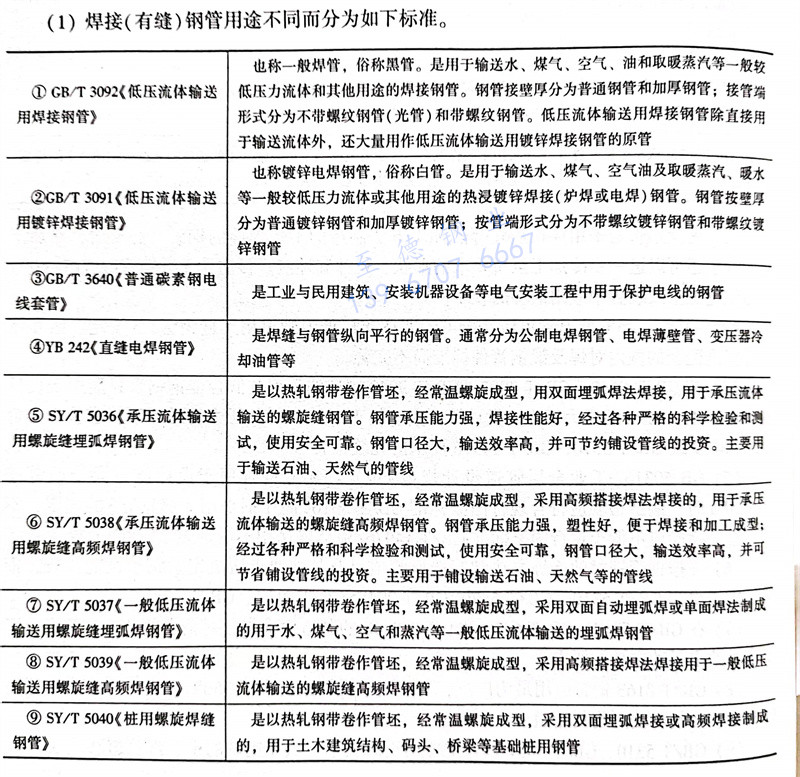

4. 有縫焊接鋼管的特點及有關標準。

①. 不銹(xiu)鋼(gang)(gang)(gang)(gang)焊(han)(han)(han)(han)(han)(han)(han)(han)(han)接鋼(gang)(gang)(gang)(gang)管(guan)(guan)(guan)(guan)(guan)也稱焊(han)(han)(han)(han)(han)(han)(han)(han)(han)管(guan)(guan)(guan)(guan)(guan),是用(yong)(yong)鋼(gang)(gang)(gang)(gang)板(ban)或(huo)鋼(gang)(gang)(gang)(gang)帶經過卷曲成(cheng)型(xing)后焊(han)(han)(han)(han)(han)(han)(han)(han)(han)接制成(cheng)的(de)(de)鋼(gang)(gang)(gang)(gang)管(guan)(guan)(guan)(guan)(guan)。不銹(xiu)鋼(gang)(gang)(gang)(gang)焊(han)(han)(han)(han)(han)(han)(han)(han)(han)接鋼(gang)(gang)(gang)(gang)管(guan)(guan)(guan)(guan)(guan)生產工(gong)藝簡單,生產效(xiao)率高(gao),品種(zhong)規(gui)格多(duo)(duo),但強(qiang)度一般(ban)低(di)于無(wu)縫(feng)(feng)鋼(gang)(gang)(gang)(gang)管(guan)(guan)(guan)(guan)(guan)。20世紀30年代以(yi)來,隨(sui)著優質帶鋼(gang)(gang)(gang)(gang)連軋生產的(de)(de)迅速發展以(yi)及焊(han)(han)(han)(han)(han)(han)(han)(han)(han)接和(he)檢驗技術的(de)(de)進(jin)步(bu),焊(han)(han)(han)(han)(han)(han)(han)(han)(han)縫(feng)(feng)質量不斷(duan)提(ti)高(gao),焊(han)(han)(han)(han)(han)(han)(han)(han)(han)接鋼(gang)(gang)(gang)(gang)管(guan)(guan)(guan)(guan)(guan)的(de)(de)品種(zhong)規(gui)格日益增(zeng)多(duo)(duo),并在越(yue)來越(yue)多(duo)(duo)的(de)(de)領域代替(ti)了無(wu)縫(feng)(feng)鋼(gang)(gang)(gang)(gang)管(guan)(guan)(guan)(guan)(guan)。焊(han)(han)(han)(han)(han)(han)(han)(han)(han)接鋼(gang)(gang)(gang)(gang)管(guan)(guan)(guan)(guan)(guan)按焊(han)(han)(han)(han)(han)(han)(han)(han)(han)縫(feng)(feng)的(de)(de)形式分為直縫(feng)(feng)焊(han)(han)(han)(han)(han)(han)(han)(han)(han)管(guan)(guan)(guan)(guan)(guan)和(he)螺旋(xuan)(xuan)焊(han)(han)(han)(han)(han)(han)(han)(han)(han)管(guan)(guan)(guan)(guan)(guan)。直縫(feng)(feng)焊(han)(han)(han)(han)(han)(han)(han)(han)(han)管(guan)(guan)(guan)(guan)(guan)生產工(gong)藝簡單,生產效(xiao)率高(gao),成(cheng)本低(di),發展較(jiao)快。螺旋(xuan)(xuan)焊(han)(han)(han)(han)(han)(han)(han)(han)(han)管(guan)(guan)(guan)(guan)(guan)的(de)(de)強(qiang)度一般(ban)比直縫(feng)(feng)焊(han)(han)(han)(han)(han)(han)(han)(han)(han)管(guan)(guan)(guan)(guan)(guan)高(gao),能用(yong)(yong)較(jiao)窄(zhai)的(de)(de)坯料(liao)生產管(guan)(guan)(guan)(guan)(guan)徑(jing)(jing)較(jiao)大(da)的(de)(de)焊(han)(han)(han)(han)(han)(han)(han)(han)(han)管(guan)(guan)(guan)(guan)(guan),還可以(yi)用(yong)(yong)同樣(yang)寬度的(de)(de)坯料(liao)生產管(guan)(guan)(guan)(guan)(guan)徑(jing)(jing)不同的(de)(de)焊(han)(han)(han)(han)(han)(han)(han)(han)(han)管(guan)(guan)(guan)(guan)(guan)。但是與相同長度的(de)(de)直縫(feng)(feng)管(guan)(guan)(guan)(guan)(guan)相比,焊(han)(han)(han)(han)(han)(han)(han)(han)(han)縫(feng)(feng)長度增(zeng)加(jia)30%~100%,而且(qie)生產速度較(jiao)低(di)。因此(ci),較(jiao)小口徑(jing)(jing)的(de)(de)焊(han)(han)(han)(han)(han)(han)(han)(han)(han)管(guan)(guan)(guan)(guan)(guan)大(da)都(dou)采用(yong)(yong)直縫(feng)(feng)焊(han)(han)(han)(han)(han)(han)(han)(han)(han),大(da)口徑(jing)(jing)焊(han)(han)(han)(han)(han)(han)(han)(han)(han)管(guan)(guan)(guan)(guan)(guan)則大(da)多(duo)(duo)采用(yong)(yong)螺旋(xuan)(xuan)焊(han)(han)(han)(han)(han)(han)(han)(han)(han)。

②. GB 50316《工業金屬(shu)管(guan)道設計(ji)規(gui)范》規(gui)定:“現(xian)行(xing)國家標準(zhun)GB/T 3092《低(di)壓(ya)流體(ti)輸(shu)(shu)送(song)用(yong)焊(han)接鋼(gang)管(guan)》及GB/T 3091《低(di)壓(ya)流體(ti)輸(shu)(shu)送(song)用(yong)鍍(du)鋅焊(han)接鋼(gang)管(guan)》中的(de)加厚(hou)管(guan)子,可用(yong)于設計(ji)壓(ya)力(li)小于等于1.6MPa和設計(ji)溫度在(zai)0~200℃的(de)C類(lei)流體(ti)。普通厚(hou)度的(de)管(guan)子僅用(yong)于D類(lei)流體(ti)。”

③. 有(you)縫(feng)鋼管(guan)通常(chang)用(yong)于低(di)壓管(guan)路。小直(zhi)(zhi)徑的(de)(de)有(you)縫(feng)鋼管(guan)(公稱(cheng)直(zhi)(zhi)徑10~150mm),常(chang)用(yong)作(zuo)(zuo)水、煤(mei)氣、空氣、低(di)壓蒸汽及無侵蝕性(xing)流體的(de)(de)管(guan)道(dao),工(gong)作(zuo)(zuo)溫度范(fan)圍為0~200℃。大直(zhi)(zhi)徑的(de)(de)有(you)縫(feng)鋼管(guan)包括螺旋縫(feng)電焊管(guan)(公稱(cheng)直(zhi)(zhi)徑200~700mm)和(he)直(zhi)(zhi)縫(feng)電焊管(guan)(公稱(cheng)直(zhi)(zhi)徑200~1200mm)。工(gong)作(zuo)(zuo)溫度范(fan)圍因材料而異。