①. 一般不銹鋼容器管道受工藝過程和容器結構的約束因素較少,所以不(bu)銹鋼管道的敷設重點在操作方便、經濟美觀。

②. 不銹(xiu)鋼容(rong)器的周圍宜分(fen)為配管(guan)區和(he)操作區,不銹(xiu)鋼管(guan)道布(bu)(bu)置在配管(guan)區,儀(yi)表、人孔和(he)梯子布(bu)(bu)置在操作區。

③. 不(bu)銹鋼(gang)管道(dao)宜(yi)沿(yan)著立式容器的(de)外壁布置,管道(dao)上(shang)的(de)閥門應與設備(bei)管口(kou)直(zhi)接連接。

④. 臥式容器下部的(de)管道如果考慮(lv)人員通行,管道距(ju)操作面的(de)凈空高度不應小于(yu)2.2m。

⑤. 不銹(xiu)鋼(gang)容器底部管道沿地(di)面敷設時,管道低(di)點排(pai)液(ye)口(kou)距(ju)地(di)面的凈距(ju)不應小于150mm。

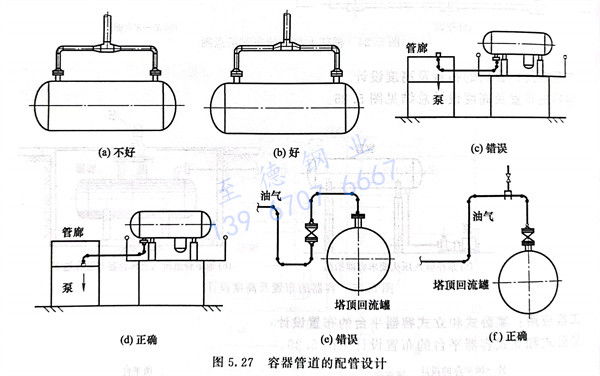

⑥. 不(bu)銹鋼容(rong)器管(guan)(guan)道配管(guan)(guan)設(she)計應滿足(zu)工藝要求(qiu)。例如(ru),入口管(guan)(guan)道避免(mian)(mian)出現(xian)袋形;有無坡(po)度(du)等(deng)要求(qiu)。如(ru)圖(tu)(tu)5.27(a)、(b)所示,為使停工時管(guan)(guan)內不(bu)積液,應采(cai)用底平的異徑(jing)管(guan)(guan)。如(ru)圖(tu)(tu)5.27(c)、(d)所示,回流油罐(guan)進(jin)泵(beng)管(guan)(guan)線(xian)(xian)不(bu)得(de)出現(xian)下(xia)袋形,防止(zhi)氣阻和汽蝕(shi),防止(zhi)泵(beng)抽空。如(ru)圖(tu)(tu)5.27所示,初餾和常壓(ya)塔頂回流罐(guan)的通往燃料氣的管(guan)(guan)線(xian)(xian),其切斷閥(fa)應靠近設(she)備管(guan)(guan)口,管(guan)(guan)線(xian)(xian)不(bu)得(de)出現(xian)袋形,以免(mian)(mian)積液影(ying)響罐(guan)內壓(ya)力,在管(guan)(guan)線(xian)(xian)的高點(dian)設(she)放(fang)空閥(fa)。

⑦. 優先考慮臥式容器的大口徑(jing)不銹(xiu)鋼(gang)管(guan)道,然后考慮其他管道,考慮支承,美觀地敷設。

⑧. 不銹鋼(gang)管道(dao)可(ke)在容(rong)器本體(ti)上(shang)設置支架。

⑨. 從立式(shi)容器上部(bu)管(guan)口(kou)下來的管(guan)道(dao)和(he)大口(kou)徑(jing)不銹鋼管(guan)道(dao)應優(you)先配(pei)置。

⑩. 不銹(xiu)鋼容(rong)器(qi)安全閥的配管設計

a. 按(an)照TSG R0004《固定式壓(ya)(ya)(ya)力(li)(li)容(rong)(rong)器(qi)(qi)(qi)安(an)(an)(an)(an)全(quan)技(ji)術(shu)監察規(gui)程》規(gui)定:壓(ya)(ya)(ya)力(li)(li)容(rong)(rong)器(qi)(qi)(qi)安(an)(an)(an)(an)全(quan)閥(fa)(fa)(fa)(fa)(fa)(fa)應(ying)當豎直安(an)(an)(an)(an)裝(zhuang)(zhuang)(zhuang)在壓(ya)(ya)(ya)力(li)(li)容(rong)(rong)器(qi)(qi)(qi)液(ye)面以上(shang)氣相(xiang)空(kong)間(jian)(jian)(jian)部分(fen),或(huo)(huo)者裝(zhuang)(zhuang)(zhuang)設在與壓(ya)(ya)(ya)力(li)(li)容(rong)(rong)器(qi)(qi)(qi)氣相(xiang)空(kong)間(jian)(jian)(jian)相(xiang)連(lian)的(de)(de)(de)管(guan)道上(shang);壓(ya)(ya)(ya)力(li)(li)容(rong)(rong)器(qi)(qi)(qi)與安(an)(an)(an)(an)全(quan)閥(fa)(fa)(fa)(fa)(fa)(fa)之(zhi)(zhi)間(jian)(jian)(jian)的(de)(de)(de)連(lian)接(jie)(jie)管(guan)和(he)管(guan)件的(de)(de)(de)通孔,其截(jie)(jie)面積不(bu)得小于(yu)(yu)安(an)(an)(an)(an)全(quan)閥(fa)(fa)(fa)(fa)(fa)(fa)的(de)(de)(de)進口(kou)(kou)截(jie)(jie)面積,其接(jie)(jie)管(guan)應(ying)當盡量短而(er)直;壓(ya)(ya)(ya)力(li)(li)容(rong)(rong)器(qi)(qi)(qi)一個(ge)連(lian)接(jie)(jie)口(kou)(kou)上(shang)裝(zhuang)(zhuang)(zhuang)設兩(liang)個(ge)或(huo)(huo)者兩(liang)個(ge)以上(shang)安(an)(an)(an)(an)全(quan)閥(fa)(fa)(fa)(fa)(fa)(fa)時,則該連(lian)接(jie)(jie)口(kou)(kou)入口(kou)(kou)的(de)(de)(de)截(jie)(jie)面積,應(ying)當至少等于(yu)(yu)這些安(an)(an)(an)(an)全(quan)閥(fa)(fa)(fa)(fa)(fa)(fa)的(de)(de)(de)進口(kou)(kou)截(jie)(jie)面積總和(he);安(an)(an)(an)(an)全(quan)閥(fa)(fa)(fa)(fa)(fa)(fa)與壓(ya)(ya)(ya)力(li)(li)容(rong)(rong)器(qi)(qi)(qi)之(zhi)(zhi)間(jian)(jian)(jian)一般不(bu)宜裝(zhuang)(zhuang)(zhuang)設截(jie)(jie)止閥(fa)(fa)(fa)(fa)(fa)(fa)門(men);為(wei)實現安(an)(an)(an)(an)全(quan)閥(fa)(fa)(fa)(fa)(fa)(fa)的(de)(de)(de)在線校驗,可在安(an)(an)(an)(an)全(quan)閥(fa)(fa)(fa)(fa)(fa)(fa)與壓(ya)(ya)(ya)力(li)(li)容(rong)(rong)器(qi)(qi)(qi)之(zhi)(zhi)間(jian)(jian)(jian)裝(zhuang)(zhuang)(zhuang)設爆(bao)破片(pian)裝(zhuang)(zhuang)(zhuang)置;對(dui)于(yu)(yu)盛裝(zhuang)(zhuang)(zhuang)毒性程度為(wei)極度、高度、中度危害(hai)介(jie)(jie)質(zhi),易燃介(jie)(jie)質(zhi),腐蝕、黏性介(jie)(jie)質(zhi)或(huo)(huo)者貴重介(jie)(jie)質(zhi)的(de)(de)(de)壓(ya)(ya)(ya)力(li)(li)容(rong)(rong)器(qi)(qi)(qi),為(wei)便于(yu)(yu)安(an)(an)(an)(an)全(quan)閥(fa)(fa)(fa)(fa)(fa)(fa)的(de)(de)(de)清洗與更(geng)換,經過使用單位主(zhu)管(guan)壓(ya)(ya)(ya)力(li)(li)容(rong)(rong)器(qi)(qi)(qi)安(an)(an)(an)(an)全(quan)技(ji)術(shu)負(fu)責人批準,并且(qie)制(zhi)定可靠的(de)(de)(de)防范措施,方可在安(an)(an)(an)(an)全(quan)閥(fa)(fa)(fa)(fa)(fa)(fa)(爆(bao)破片(pian)裝(zhuang)(zhuang)(zhuang)置)與壓(ya)(ya)(ya)力(li)(li)容(rong)(rong)器(qi)(qi)(qi)之(zhi)(zhi)間(jian)(jian)(jian)裝(zhuang)(zhuang)(zhuang)設截(jie)(jie)止閥(fa)(fa)(fa)(fa)(fa)(fa)門(men),壓(ya)(ya)(ya)力(li)(li)容(rong)(rong)器(qi)(qi)(qi)正常運行期間(jian)(jian)(jian)截(jie)(jie)止閥(fa)(fa)(fa)(fa)(fa)(fa)門(men)必須保證全(quan)開(kai)(加鉛封或(huo)(huo)者鎖定),截(jie)(jie)止閥(fa)(fa)(fa)(fa)(fa)(fa)門(men)的(de)(de)(de)結構(gou)和(he)通徑不(bu)得妨礙安(an)(an)(an)(an)全(quan)閥(fa)(fa)(fa)(fa)(fa)(fa)的(de)(de)(de)安(an)(an)(an)(an)全(quan)閥(fa)(fa)(fa)(fa)(fa)(fa)的(de)(de)(de)安(an)(an)(an)(an)全(quan)泄放(fang)。

b. 不(bu)銹鋼容(rong)器安全閥設(she)計安裝位(wei)置(zhi)靠近容(rong)器的主管位(wei)置(zhi),遠距離設(she)置(zhi)時,要(yao)進行壓降核算。

c. 安全(quan)閥跳動時(shi),產生推力,應設計(ji)抗推力的支架。

d. 排(pai)向大氣的噴出管口(kou)(kou)肘(zhou)部設(she)置淚孔(kong),以便于液(ye)體和雨(yu)水排(pai)出。排(pai)放不要朝向通道口(kou)(kou)。

e. 多個安全閥相鄰安裝時,排出管采用(yong)集合管形式。

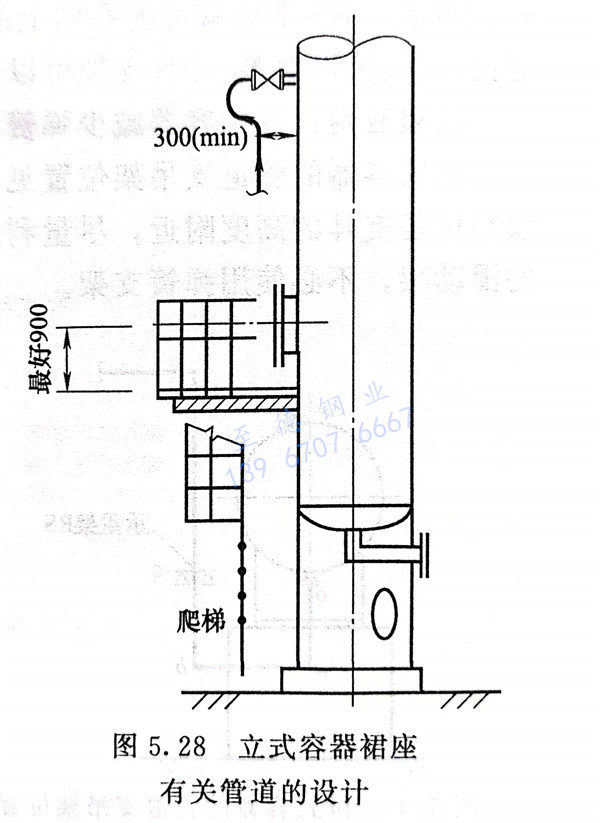

?. 立式容(rong)器若采用(yong)裙座(zuo)式支撐,容(rong)器底部的所有管口應采用(yong)管線把接口法蘭引(yin)到裙座(zuo)外側,裙座(zuo)內不得(de)安裝法蘭和閥門等,見(jian)圖5.28。

?. 受熱作用的管(guan)道應考(kao)慮其柔性(xing)要求。例(li)如,與離心壓縮機相接的管(guan)道;儀(yi)表用的較長連接管(guan)。

?. 產生(sheng)振動的管道應(ying)對支架(jia)進行加固。