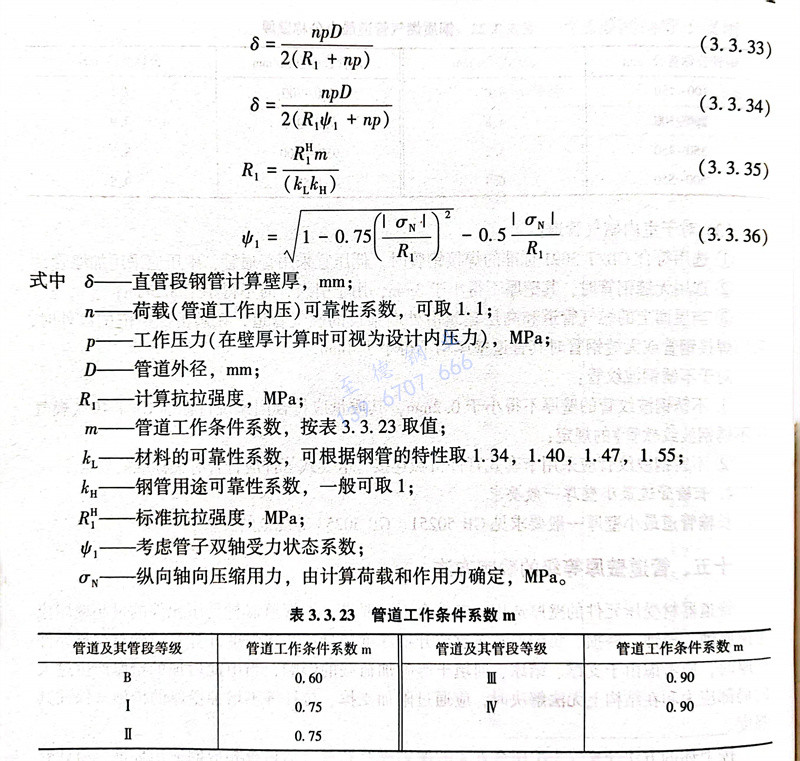

對于輸(shu)油(you)和輸(shu)氣管(guan)(guan)(guan)道(dao)(dao)的壁(bi)(bi)厚(hou)(hou)計(ji)算(suan),俄羅斯(si)管(guan)(guan)(guan)道(dao)(dao)規范(fan)和國內(nei)管(guan)(guan)(guan)道(dao)(dao)規范(fan)所采(cai)用(yong)的公式差別(bie)較大(da),根據俄羅斯(si)管(guan)(guan)(guan)道(dao)(dao)規范(fan)SNIP 2.05.06《干線管(guan)(guan)(guan)道(dao)(dao)設計(ji)規范(fan)》的規定(ding),管(guan)(guan)(guan)道(dao)(dao)壁(bi)(bi)厚(hou)(hou)由式(3.3.33)和式(3.3.34)計(ji)算(suan)確(que)定(ding)。當存在縱(zong)向和軸向壓(ya)縮應力(li)時,壁(bi)(bi)厚(hou)(hou)應根據式(3.3.34)確(que)定(ding)。

輸(shu)(shu)(shu)油(you)管(guan)(guan)(guan)(guan)道(dao)(dao)鋼(gang)管(guan)(guan)(guan)(guan)管(guan)(guan)(guan)(guan)壁(bi)厚計(ji)(ji)(ji)(ji)(ji)算(suan)公(gong)式見(jian) GB 50253《輸(shu)(shu)(shu)油(you)管(guan)(guan)(guan)(guan)道(dao)(dao)工程(cheng)設計(ji)(ji)(ji)(ji)(ji)規(gui)范(fan)》。輸(shu)(shu)(shu)氣(qi)管(guan)(guan)(guan)(guan)道(dao)(dao)鋼(gang)管(guan)(guan)(guan)(guan)管(guan)(guan)(guan)(guan)壁(bi)厚度(du)計(ji)(ji)(ji)(ji)(ji)算(suan)見(jian)GB50251《輸(shu)(shu)(shu)氣(qi)管(guan)(guan)(guan)(guan)道(dao)(dao)工程(cheng)設計(ji)(ji)(ji)(ji)(ji)規(gui)范(fan)》。公(gong)式中(zhong)的參數F.與俄羅斯管(guan)(guan)(guan)(guan)道(dao)(dao)壁(bi)厚計(ji)(ji)(ji)(ji)(ji)算(suan)公(gong)式中(zhong)的參數k含義一(yi)(yi)樣(yang),只(zhi)是(shi)F應根據地區(qu)類別取不同(tong)的值。在我國規(gui)范(fan)中(zhong),輸(shu)(shu)(shu)油(you)管(guan)(guan)(guan)(guan)道(dao)(dao)和輸(shu)(shu)(shu)氣(qi)管(guan)(guan)(guan)(guan)道(dao)(dao)的直(zhi)管(guan)(guan)(guan)(guan)段壁(bi)厚計(ji)(ji)(ji)(ji)(ji)算(suan)公(gong)式基(ji)本相(xiang)同(tong),不同(tong)的是(shi)輸(shu)(shu)(shu)氣(qi)管(guan)(guan)(guan)(guan)道(dao)(dao)壁(bi)厚計(ji)(ji)(ji)(ji)(ji)算(suan)設計(ji)(ji)(ji)(ji)(ji)系(xi)數的取值不一(yi)(yi)樣(yang),另外(wai),輸(shu)(shu)(shu)氣(qi)管(guan)(guan)(guan)(guan)道(dao)(dao)還需(xu)考慮溫度(du)折(zhe)減系(xi)數t。

將俄(e)羅斯管(guan)道規(gui)范中(zhong)的(de)壁厚(hou)計算公式與我國規(gui)范計算公式比較可知,兩(liang)者(zhe)在壁厚(hou)的(de)計算上有(you)很大(da)的(de)不同(tong)。

(1)俄(e)羅斯規(gui)范對壁厚的(de)計算考(kao)慮的(de)因(yin)素(su)較多,如荷載(zai)可靠性系(xi)數(shu)(shu)n、工作條(tiao)件(jian)系(xi)數(shu)(shu)m、材料的(de)可靠性系(xi)數(shu)(shu)kL和鋼管(guan)用途可靠性系(xi)數(shu)(shu)kH等。而我國的(de)規(gui)范中(zhong)僅(jin)考(kao)慮了設計系(xi)數(shu)(shu)k及焊縫系(xi)數(shu)(shu)中(zhong)。

(2)俄羅(luo)斯規范中壁(bi)厚的(de)計算采(cai)(cai)用(yong)的(de)是(shi)標(biao)準抗(kang)(kang)拉強度(du),而我國規范中采(cai)(cai)用(yong)的(de)是(shi)最(zui)小屈服強度(du)。抗(kang)(kang)拉強度(du)和最(zui)小屈服強度(du)在數(shu)值上(shang)有較大的(de)區別,例如,根據(ju)API 5L《管道鋼管規范》,X65材料標(biao)準抗(kang)(kang)拉強度(du)是(shi)531MPa,最(zui)小屈服強度(du)是(shi)448MPa。

(3)在(zai)俄羅斯(si)管(guan)道規范(fan)中,當(dang)鋼管(guan)存在(zai)縱向和(he)軸向壓縮應力(li)時,還考慮了管(guan)子雙軸受力(li)狀態系數↓1。我國規范(fan)中未包括這種情況。

(4)采用俄羅斯管道規(gui)范計算(suan)的(de)壁厚(hou)與我國(guo)規(gui)范計算(suan)的(de)壁厚(hou)有一定(ding)的(de)差異,但(dan)不是太大,前者(zhe)比后者(zhe)保守。

(5)按GB50253規(gui)(gui)定(ding),輸油(you)管(guan)道工(gong)程設計(ji)(ji)計(ji)(ji)算輸油(you)量時,年(nian)工(gong)作天數(shu)應按350天計(ji)(ji)算,而(er)俄羅斯規(gui)(gui)范BHTH 2-86《干線輸油(you)管(guan)道工(gong)藝設計(ji)(ji)規(gui)(gui)范》中規(gui)(gui)定(ding),輸油(you)管(guan)道的年(nian)工(gong)作天數(shu)應根據管(guan)道長(chang)度和管(guan)道直(zhi)徑來(lai)選取,工(gong)作天數(shu)從(cong)345~356。