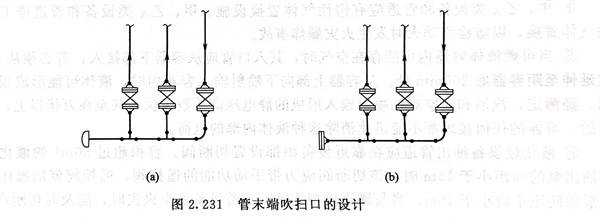

①. 可(ke)燃氣體、液化(hua)(hua)烴和(he)可(ke)燃液體的(de)(de)(de)(de)金(jin)屬(shu)管(guan)(guan)道(dao)除(chu)規定(ding)需要(yao)采(cai)(cai)(cai)用(yong)法(fa)蘭(lan)(lan)連(lian)接(jie)外,均應(ying)采(cai)(cai)(cai)用(yong)焊(han)接(jie)連(lian)接(jie)。公稱直徑(jing)等于或小(xiao)于25mm的(de)(de)(de)(de)可(ke)燃氣體、液化(hua)(hua)烴和(he)可(ke)燃液體的(de)(de)(de)(de)金(jin)屬(shu)管(guan)(guan)道(dao)和(he)閥門采(cai)(cai)(cai)用(yong)錐(zhui)管(guan)(guan)螺紋連(lian)接(jie)時,除(chu)能產生(sheng)縫隙腐蝕(shi)的(de)(de)(de)(de)介質(zhi)管(guan)(guan)道(dao)外,應(ying)在螺紋處采(cai)(cai)(cai)用(yong)密封(feng)焊(han)。規定(ding)采(cai)(cai)(cai)用(yong)法(fa)蘭(lan)(lan)連(lian)接(jie)的(de)(de)(de)(de)地方為:與設備管(guan)(guan)口法(fa)蘭(lan)(lan)的(de)(de)(de)(de)連(lian)接(jie)、與法(fa)蘭(lan)(lan)閥門的(de)(de)(de)(de)連(lian)接(jie)等;高(gao)(gao)黏度、易黏結的(de)(de)(de)(de)聚合淤漿液和(he)懸浮液等易堵(du)塞的(de)(de)(de)(de)管(guan)(guan)道(dao);凝(ning)固點高(gao)(gao)的(de)(de)(de)(de)液狀石(shi)蠟、瀝青、硫(liu)黃等管(guan)(guan)道(dao);停工檢修(xiu)需拆卸(xie)的(de)(de)(de)(de)管(guan)(guan)道(dao)等。需要(yao)經常清掃的(de)(de)(de)(de)分配主管(guan)(guan),管(guan)(guan)的(de)(de)(de)(de)一端不能封(feng)閉,應(ying)做成能拆卸(xie)的(de)(de)(de)(de)形(xing)式,見圖2.231。

管(guan)道(dao)采(cai)用焊(han)接(jie)連(lian)接(jie),不論從強度上、密(mi)封(feng)性能上都(dou)是(shi)好的(de)(de)。但(dan)是(shi),等于或小于DN25的(de)(de)管(guan)道(dao),其焊(han)接(jie)強度不佳且易將焊(han)渣落入管(guan)內引起管(guan)道(dao)堵(du)塞(sai),因此多采(cai)用承插(cha)焊(han)管(guan)件連(lian)接(jie),也可采(cai)用錐管(guan)螺(luo)紋連(lian)接(jie)。當采(cai)用錐管(guan)螺(luo)紋連(lian)接(jie)時,有強腐蝕性介(jie)質,尤(you)其是(shi)含HF等易產(chan)生縫隙(xi)腐蝕的(de)(de)介(jie)質,不得在(zai)螺(luo)紋連(lian)接(jie)處(chu)施以密(mi)封(feng)焊(han),否則一旦泄(xie)漏,后果嚴(yan)重。

②. 可燃氣(qi)體(ti)、液化烴和可燃液體(ti)的(de)管(guan)道不(bu)得穿過與(yu)其無關的(de)建筑(zhu)物。可燃氣(qi)體(ti)、液化烴和可燃液體(ti)的(de)采樣管(guan)道不(bu)應(ying)引入化驗室。

③. 可(ke)燃(ran)(ran)氣體、液(ye)化(hua)烴和可(ke)燃(ran)(ran)液(ye)體的(de)管道應(ying)(ying)架空或(huo)沿地敷(fu)設。日常檢查、檢修各方面(mian)都(dou)比較方便,而管溝(gou)(gou)和埋地敷(fu)設恰好相反(fan),破損不易被及(ji)(ji)時(shi)發現。必須(xu)采用管溝(gou)(gou)敷(fu)設時(shi),應(ying)(ying)采取防止可(ke)燃(ran)(ran)氣體、液(ye)化(hua)烴和可(ke)燃(ran)(ran)液(ye)體在(zai)管溝(gou)(gou)內積聚的(de)措施,并(bing)在(zai)進(jin)、出裝置及(ji)(ji)廠(chang)(chang)房處(chu)密封隔(ge)斷;管溝(gou)(gou)內的(de)污水(shui)(shui)應(ying)(ying)經(jing)水(shui)(shui)封井排人生產(chan)污水(shui)(shui)管道。管溝(gou)(gou)在(zai)進(jin)出廠(chang)(chang)房及(ji)(ji)裝置處(chu)應(ying)(ying)妥(tuo)善隔(ge)斷,是為了阻止火災(zai)蔓(man)延(yan)和可(ke)燃(ran)(ran)氣體或(huo)可(ke)燃(ran)(ran)液(ye)體流(liu)竄。

④. 工(gong)藝和公用工(gong)程管(guan)(guan)道共架多層(ceng)(ceng)敷設時,宜(yi)將介質(zhi)操作(zuo)(zuo)(zuo)溫(wen)度(du)等于(yu)或高(gao)于(yu)250℃的(de)管(guan)(guan)道布置(zhi)在(zai)(zai)上層(ceng)(ceng),液化烴及腐(fu)蝕性介質(zhi)管(guan)(guan)道布置(zhi)在(zai)(zai)下層(ceng)(ceng);必須布置(zhi)在(zai)(zai)下層(ceng)(ceng)的(de)介質(zhi)操作(zuo)(zuo)(zuo)溫(wen)度(du)等于(yu)或高(gao)于(yu)250℃的(de)管(guan)(guan)道可(ke)布置(zhi)在(zai)(zai)外側(ce),但不應與液化烴管(guan)(guan)道相鄰。大多數塔(ta)底泵的(de)介質(zhi)操作(zuo)(zuo)(zuo)溫(wen)度(du)等于(yu)或高(gao)于(yu)250℃,當(dang)塔(ta)底泵布置(zhi)在(zai)(zai)管(guan)(guan)廊(橋)下時,為(wei)盡可(ke)能降低(di)塔(ta)的(de)液面高(gao)度(du),并(bing)能滿足泵的(de)有效汽(qi)蝕余量(liang)的(de)要(yao)求。

⑤. 氧(yang)氣管(guan)(guan)道與(yu)可燃氣體(ti)、液(ye)化烴(jing)和(he)可燃液(ye)體(ti)的管(guan)(guan)道共架敷設時(shi)(shi)應(ying)布(bu)置在一(yi)側(ce),且平行布(bu)置時(shi)(shi)凈距不(bu)應(ying)小(xiao)(xiao)于500mm,交叉(cha)布(bu)置時(shi)(shi)凈距不(bu)應(ying)小(xiao)(xiao)于250mm。氧(yang)氣管(guan)(guan)道與(yu)可燃氣體(ti)、液(ye)化烴(jing)和(he)可燃液(ye)體(ti)管(guan)(guan)道之(zhi)間宜用公用工程管(guan)(guan)道隔開。

氧氣管道(dao)與可燃介質管道(dao)共架敷設時,兩管道(dao)平(ping)行布置(zhi)的凈距(ju)(ju)為不小于(yu)500mm。但當(dang)管道(dao)采用焊接(jie)連接(jie)結(jie)構并無(wu)閥門時,其平(ping)行布置(zhi)的凈距(ju)(ju)可取上述凈距(ju)(ju)的50%,即250mm。

⑥. 公(gong)用(yong)(yong)工(gong)(gong)程管道(dao)在(zai)(zai)(zai)工(gong)(gong)藝裝置中(zhong)是經常(chang)與可燃(ran)(ran)(ran)氣體(ti)(ti)、液(ye)化烴、可燃(ran)(ran)(ran)液(ye)體(ti)(ti)的(de)(de)設(she)(she)備和(he)管道(dao)相連(lian)(lian)接的(de)(de)。當公(gong)用(yong)(yong)工(gong)(gong)程管道(dao)壓力因故降低時,大(da)量可燃(ran)(ran)(ran)液(ye)體(ti)(ti)可能倒(dao)流(liu)入(ru)公(gong)用(yong)(yong)工(gong)(gong)程管道(dao)內(nei),容易引(yin)發事故。如(ru)大(da)量可燃(ran)(ran)(ran)液(ye)體(ti)(ti)倒(dao)流(liu)入(ru)蒸汽管道(dao)內(nei),當用(yong)(yong)蒸汽滅(mie)火(huo)時起了“火(huo)上添油的(de)(de)作用(yong)(yong)”。因此,公(gong)用(yong)(yong)工(gong)(gong)程管道(dao)與可燃(ran)(ran)(ran)氣體(ti)(ti)、液(ye)化烴和(he)可燃(ran)(ran)(ran)液(ye)體(ti)(ti)的(de)(de)管道(dao)或設(she)(she)備連(lian)(lian)接時應符合下列規定:連(lian)(lian)續使(shi)用(yong)(yong)的(de)(de)公(gong)用(yong)(yong)工(gong)(gong)程管道(dao)上應設(she)(she)止回閥(fa),并在(zai)(zai)(zai)其根部(bu)設(she)(she)切斷閥(fa);在(zai)(zai)(zai)間歇使(shi)用(yong)(yong)的(de)(de)公(gong)用(yong)(yong)工(gong)(gong)程管道(dao)上應設(she)(she)止回閥(fa)和(he)一道(dao)切斷閥(fa)或設(she)(she)兩道(dao)切斷閥(fa),并在(zai)(zai)(zai)兩切斷閥(fa)間設(she)(she)檢(jian)查閥(fa);僅(jin)在(zai)(zai)(zai)設(she)(she)備停(ting)用(yong)(yong)時使(shi)用(yong)(yong)的(de)(de)公(gong)用(yong)(yong)工(gong)(gong)程管道(dao)應設(she)(she)盲板或斷開。

止(zhi)回閥是重要的安全設施,但只能(neng)防止(zhi)大量(liang)氣體、液(ye)體倒流,不能(neng)阻止(zhi)少量(liang)泄漏。

⑦. 連續(xu)操(cao)作(zuo)的(de)可燃(ran)氣(qi)體(ti)管道的(de)低(di)點應設兩(liang)(liang)道排液(ye)(ye)閥(fa)(fa),排出的(de)液(ye)(ye)體(ti)應排放至密閉系統;僅在開停工時(shi)使用的(de)排液(ye)(ye)閥(fa)(fa),可設一道閥(fa)(fa)門(men)(men)并加絲(si)堵、管帽、盲(mang)板或法蘭蓋。連續(xu)操(cao)作(zuo)的(de)可燃(ran)氣(qi)體(ti)管道的(de)低(di)點設兩(liang)(liang)道排液(ye)(ye)閥(fa)(fa),第(di)一道(靠(kao)近(jin)管道側)閥(fa)(fa)門(men)(men)為常開閥(fa)(fa),第(di)二道閥(fa)(fa)門(men)(men)為經常操(cao)作(zuo)閥(fa)(fa)。當發現第(di)二道閥(fa)(fa)門(men)(men)泄漏時(shi),關閉第(di)一道閥(fa)(fa)門(men)(men),更換第(di)二道閥(fa)(fa)門(men)(men)。

⑧. 甲、乙A類設(she)備(bei)和管道應(ying)有惰(duo)性氣體置換(huan)設(she)施。甲、乙A類設(she)備(bei)和管道停工(gong)時應(ying)用惰(duo)性氣體置換(huan),以防(fang)檢修動火時發生火災爆炸事故。

⑨. 當可燃液(ye)(ye)(ye)體(ti)容器內(nei)可能(neng)存在空(kong)氣時,其入(ru)口(kou)管應從容器下部接入(ru);若必(bi)須從上(shang)部接入(ru),應延伸至(zhi)距容器底200mm處。從容器上(shang)部向下噴射(she)輸入(ru)容器內(nei)時,液(ye)(ye)(ye)體(ti)可能(neng)形(xing)成(cheng)很高的(de)靜電(dian)(dian)壓(ya),經測定,汽油和航空(kong)煤油噴射(she)輸入(ru)形(xing)成(cheng)的(de)靜電(dian)(dian)壓(ya)高達數千(qian)伏,甚至(zhi)在萬伏以(yi)上(shang),這是很危險的(de)。容器的(de)任何接地(di)都不能(neng)迅(xun)速(su)消(xiao)除這種液(ye)(ye)(ye)體(ti)內(nei)部的(de)電(dian)(dian)荷(he)。

⑩. 液化烴設備抽出管道應在靠近設備根部設置切斷閥。容積超過50m3的液化烴設備與其抽出泵的間距小于15m時,該切斷閥應為帶手動功能的遙控閥,遙控閥就地操作按鈕距抽出泵的間距不應小于15m。當與罐直接相連接的下游設備發生火災時,能及時切斷物料。