寶鋼φ610mm HFW 直縫焊管機組引進德國 SMS MEER等世界上最先進的直縫不銹鋼焊(han)管生產設備,投產于2005年10月,設計年產30萬噸直縫焊管。該生產線是世界上第一條集先進成型技術、大功率焊接、功能齊全的無損探傷技術、焊縫雙重熱處理和全管體熱處理設備、全過程的計算機料流跟蹤系統于一體的中口徑直縫焊管生產線。是世界上裝備最先進的HFW焊管生產線之一,是國內唯一一條集煉鋼、熱軋、制管、涂層一體化的HFW不銹鋼焊管生產線。可以生產管線管、套管、結構管等HFW不銹鋼焊管產品。

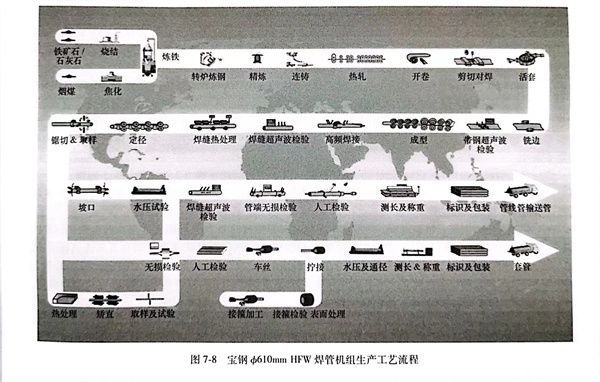

一、生產工藝流程

寶鋼(gang)ф610mm HFW不銹鋼(gang)焊管機組生產工(gong)藝(yi)流程見(jian)圖7-8所示。

二、主要技術特點

1. 排(pai)輥成型技術特點

a. 由許多小(xiao)直(zhi)徑輥組成(cheng)的(de)排輥代(dai)替輥式成(cheng)型機的(de)大直(zhi)徑水(shui)平輥,最(zui)大邊緣拉(la)應(ying)變僅是傳統輥式成(cheng)型的(de)1/5左右,可(ke)提高鋼管(guan)外觀質(zhi)量,減(jian)少功率消耗及軋輥磨損。

b. 排(pai)輥成型(xing)機采用連續(xu)局部(bu)彎曲(qu)變形,彎曲(qu)力(li)小且較均(jun)勻(yun);成型(xing)區縮(suo)短,帶鋼(gang)塑性變形小;排(pai)輥群(qun)由外側束縛帶鋼(gang)邊(bian)緣(yuan)(yuan),將邊(bian)緣(yuan)(yuan)外側變形以(yi)壓(ya)縮(suo)形式吸收,可(ke)防止(zhi)帶鋼(gang)邊(bian)緣(yuan)(yuan)發(fa)生(sheng)折(zhe)皺、鼓包,使(shi)鋼(gang)管(guan)壁厚與(yu)管(guan)徑(jing)比的范圍擴(kuo)大(da)到1:80,具(ju)有加(jia)工中大(da)直徑(jing)薄壁管(guan)的優(you)勢。

c. 排輥成型(xing)(xing)為連(lian)續(xu)成型(xing)(xing)法(fa),成型(xing)(xing)性好,且采用“下山法(fa)”成型(xing)(xing),在(zai)成型(xing)(xing)過程中帶鋼邊緣的軌跡近(jin)乎(hu)直線,從而改善成型(xing)(xing)質(zhi)量,使焊接穩定可靠。

d. 在更(geng)換不銹鋼(gang)焊管規格尺寸(cun)時(shi),排輥(gun)不換,只需調(diao)整(zheng),與傳統(tong)輥(gun)式成(cheng)型相比,可減少軋(ya)輥(gun)規格和換輥(gun)時(shi)間。

2. 成型設備技(ji)術特點(dian)

寶(bao)鋼Φ610mm HFW焊管機(ji)組(zu)成型(xing)設備是(shi)引進德國(guo)SMSMEER公司(si)開(kai)發的(de)直緣(yuan)成型(xing)技術,由夾送輥裝置、彎邊機(ji)、線性(xing)預成型(xing)裝置、粗成型(xing)機(ji)、線性(xing)成型(xing)裝置、精成型(xing)機(ji)架(jia)、擠壓輥機(ji)架(jia)和(he)定(ding)徑機(ji)架(jia)組(zu)成。

a. 夾(jia)送輥(gun)裝置(zhi)由上、下水平輥(gun)組成,2臺(tai)功率為110kW交流電(dian)機通(tong)過減速齒輪箱和萬向傳動(dong)軸(zhou)驅動(dong)將(jiang)帶(dai)鋼經水平導向輥(gun)送入彎邊機,并在(zai)生產(chan)中(zhong)(zhong)作輔助主傳動(dong)。上夾(jia)送輥(gun)由液壓缸升、降,帶(dai)鋼在(zai)機架中(zhong)(zhong)不產(chan)生彎曲變(bian)形,出本機架后(hou)開始“下山”變(bian)形。

b. 彎(wan)(wan)邊(bian)(bian)機(ji)(ji)位于線(xian)性預成(cheng)型(xing)裝(zhuang)置前端,將帶鋼邊(bian)(bian)緣彎(wan)(wan)曲成(cheng)接(jie)近成(cheng)品曲率的弧形(xing),防止焊(han)縫處(chu)出現梨形(xing)凸(tu)出,一(yi)對彎(wan)(wan)邊(bian)(bian)輥(gun)可一(yi)起上下(xia)、左右調(diao)(diao)整(zheng)(zheng),也(ye)可以單獨調(diao)(diao)整(zheng)(zheng),通(tong)過(guo)(guo)電機(ji)(ji)和(he)螺旋千斤頂可以調(diao)(diao)節彎(wan)(wan)邊(bian)(bian)厚(hou)度(du)和(he)寬度(du),為確保(bao)不同壁厚(hou)精確的帶鋼邊(bian)(bian)部彎(wan)(wan)曲以及(ji)允許(xu)對頭(tou)焊(han)縫自由通(tong)過(guo)(guo),下(xia)彎(wan)(wan)邊(bian)(bian)輥(gun)設計成(cheng)液壓減震結(jie)構(gou)。上下(xia)彎(wan)(wan)邊(bian)(bian)輥(gun)均安裝(zhuang)在用于快速(su)更換的箱式結(jie)構(gou)的輥(gun)座上,通(tong)過(guo)(guo)編碼器(qi)傳(chuan)感、計算機(ji)(ji)控制調(diao)(diao)整(zheng)(zheng)輥(gun)位。

c. 線性預成型(xing)(xing)裝置由2個帶有若(ruo)干非傳動排輥的外部線性成型(xing)(xing)裝置(排輥架)組成,以確(que)保(bao)短成型(xing)(xing)間距,其線性可根據產品(pin)成型(xing)(xing)的幾何學進(jin)行水(shui)平(ping)、垂(chui)直(zhi)和旋轉調節(jie)。

d. 粗成(cheng)(cheng)(cheng)型機由上(shang)輥(gun)和下輥(gun)組成(cheng)(cheng)(cheng),并(bing)布置在線性預(yu)成(cheng)(cheng)(cheng)型后段,由2臺功率110kW交流電(dian)機通過減速齒(chi)輪箱和萬(wan)向傳動(dong)軸驅動(dong),是(shi)線性預(yu)成(cheng)(cheng)(cheng)型段及粗成(cheng)(cheng)(cheng)型的主動(dong)力源。

e. 線(xian)性成(cheng)(cheng)型(xing)裝(zhuang)(zhuang)置布置在線(xian)性預(yu)成(cheng)(cheng)型(xing)裝(zhuang)(zhuang)置和(he)精成(cheng)(cheng)型(xing)機架之間,分(fen)為3段(duan),每段(duan)有2個排(pai)輥架組成(cheng)(cheng),可(ke)以根據產(chan)品成(cheng)(cheng)型(xing)幾(ji)何學(xue)需求(qiu)進(jin)行水平、垂直和(he)旋轉(zhuan)調節。帶鋼經線(xian)性成(cheng)(cheng)型(xing)裝(zhuang)(zhuang)置后成(cheng)(cheng)為U形。

f. 精成(cheng)(cheng)型(xing)(xing)機(ji)架(jia)(jia)由(you)3架(jia)(jia)精成(cheng)(cheng)型(xing)(xing)機(ji)架(jia)(jia)組成(cheng)(cheng),采用均勻剛(gang)性設計(ji)的(de)(de)(de)URD機(ji)架(jia)(jia)由(you)6臺(tai)功率為110kW交流電機(ji)通過減速齒輪箱和萬向(xiang)(xiang)傳動(dong)軸驅動(dong),是(shi)成(cheng)(cheng)型(xing)(xing)焊(han)接(jie)(jie)段的(de)(de)(de)主動(dong)力(li)源(yuan)。每(mei)架(jia)(jia)精成(cheng)(cheng)型(xing)(xing)機(ji)架(jia)(jia)安裝(zhuang)4個(ge)(ge)軋(ya)輥(gun),上(shang)、下(xia)輥(gun)主動(dong),2個(ge)(ge)側輥(gun)被動(dong),最大軋(ya)制(zhi)力(li)1800kN。上(shang)、下(xia)輥(gun)及側輥(gun)通過獨立的(de)(de)(de)小電機(ji)經螺(luo)旋(xuan)升(sheng)降裝(zhuang)置調節,編碼器傳感,計(ji)算機(ji)控(kong)制(zhi)調整輥(gun)位,輥(gun)位OP值設定精度可達0.01mm。精成(cheng)(cheng)型(xing)(xing)將(jiang)線性成(cheng)(cheng)型(xing)(xing)后(hou)的(de)(de)(de)U形(xing)(xing)荒管(guan)變形(xing)(xing)為開口的(de)(de)(de)0形(xing)(xing)管(guan)坯。3架(jia)(jia)上(shang)輥(gun)安裝(zhuang)導向(xiang)(xiang)環將(jiang)焊(han)接(jie)(jie)V角控(kong)制(zhi)在一(yi)定的(de)(de)(de)范圍內,為擠壓(ya)輥(gun)機(ji)架(jia)(jia)的(de)(de)(de)成(cheng)(cheng)型(xing)(xing)焊(han)接(jie)(jie)創造(zao)了條(tiao)件。

g. 擠壓輥(gun)(gun)機(ji)架采(cai)用均勻剛性設(she)計的URD機(ji)架,由5個(ge)(ge)被動擠壓輥(gun)(gun)(2個(ge)(ge)上(shang)輥(gun)(gun),2個(ge)(ge)側輥(gun)(gun),1個(ge)(ge)底輥(gun)(gun))組成的孔型,可將精(jing)成型后的開(kai)口(kou)0形管成型焊接成封閉(bi)的0形管。該機(ji)架也(ye)具(ju)有精(jing)成型機(ji)架軋輥(gun)(gun)精(jing)密調(diao)節機(ji)構和快速換輥(gun)(gun)功能。

h. 定(ding)徑(jing)(jing)(jing)(jing)段由(you)4架(jia)定(ding)徑(jing)(jing)(jing)(jing)機(ji)(ji)架(jia)組(zu)成(cheng),主要功(gong)能是(shi)將成(cheng)型焊接后的(de)0形立橢圓管變(bian)形為(wei)符(fu)合產(chan)品標準的(de)圓管,采用均勻剛性設(she)計的(de)URD機(ji)(ji)架(jia)由(you)8臺功(gong)率為(wei)110kW交流電(dian)機(ji)(ji)通(tong)過減速齒輪箱和萬向(xiang)傳動軸驅動,是(shi)定(ding)徑(jing)(jing)(jing)(jing)段的(de)主動力源。每架(jia)定(ding)徑(jing)(jing)(jing)(jing)機(ji)(ji)架(jia)裝(zhuang)有4個軋輥(gun)(gun),其(qi)中上(shang)、下輥(gun)(gun)主動,2個側輥(gun)(gun)被動,最大軋制力1800kN。上(shang)、下輥(gun)(gun)及側輥(gun)(gun)通(tong)過獨立的(de)小(xiao)電(dian)機(ji)(ji)并經(jing)螺旋千斤頂調節,編碼器傳感,計算機(ji)(ji)控制調整輥(gun)(gun)位,輥(gun)(gun)位OP值設(she)定(ding)精度可達0.01mm。為(wei)保證小(xiao)直(zhi)徑(jing)(jing)(jing)(jing)(219.1~323.9mm)焊管焊縫在定(ding)徑(jing)(jing)(jing)(jing)前不偏(pian)離12點的(de)位置(zhi)(zhi),在1#定(ding)徑(jing)(jing)(jing)(jing)機(ji)(ji)架(jia)前設(she)置(zhi)(zhi)了(le)防扭轉機(ji)(ji)架(jia),防扭轉機(ji)(ji)架(jia)上(shang)安裝(zhuang)了(le)一對可沿環向(xiang)扭轉的(de)立輥(gun)(gun),并配(pei)置(zhi)(zhi)了(le)快速夾緊、機(ji)(ji)械調節裝(zhuang)置(zhi)(zhi)。

3. 固態焊機(ji)技術特點

采用挪(nuo)威(wei)EFD公司生產的(de)輸(shu)出功率(lv)為1800kW、頻率(lv)90~150kHz的(de)固(gu)態焊機(ji)。用更加簡(jian)潔(jie)的(de)主回路拓撲(pu)結構(gou),二極管不可控整流,可使功率(lv)因數(shu)達(da)到0.95;利用新型(xing)的(de)軟開關橋式逆(ni)變換(huan)流技(ji)術(shu)將輸(shu)入(ru)的(de)直流電(dian)逆(ni)變為高頻交流電(dian);整機(ji)效(xiao)率(lv)可達(da)85%左右。具有高頻電(dian)源保護;無需(xu)對主回路的(de)電(dian)容(rong)電(dian)感參數(shu)進(jin)行調節,在設計負(fu)載范圍內,功率(lv)正常輸(shu)出不受(shou)限制(zhi),自動匹配(pei);還具有開機(ji)自診(zhen)斷功能、配(pei)備(bei)相應的(de)通訊系(xi)統實時將設備(bei)運行參數(shu)傳遞到監控系(xi)統進(jin)行診(zhen)斷處理(li)及(ji)存儲等智能化功能。

4. 自動控制系統技術特點(dian)

a. 自(zi)動(dong)(dong)控制系(xi)統分為:制造執(zhi)行級(ji) MES(manufacturing execution system)、基礎自(zi)動(dong)(dong)化級(ji)L1和設備傳動(dong)(dong)與(yu)檢(jian)測級(ji)LO等3個層次。焊管生產線PLC與(yu)MES、操作PC、快(kuai)速設定PC之間均采(cai)用(yong)標(biao)準工業以太網(wang)通(tong)訊,PLC與(yu)傳動(dong)(dong)、檢(jian)測設備間采(cai)用(yong)網(wang)絡通(tong)訊連接。

b. MES主要功能是接收(shou)上級計算機(ji)(ERP)下達的生(sheng)產(chan)計劃(hua),轉化成實(shi)際的產(chan)品(pin)制造計劃(hua)和(he)設備控(kong)制參數,并控(kong)制實(shi)際生(sheng)產(chan)過(guo)程(cheng),完成生(sheng)產(chan)線調度、物(wu)料跟(gen)蹤和(he)生(sheng)產(chan)數據(ju)采集等功能,實(shi)現(xian)產(chan)品(pin)從(cong)生(sheng)產(chan)計劃(hua)到成品(pin)產(chan)出全過(guo)程(cheng)管理與(yu)控(kong)制。

c. 快(kuai)速(su)設(she)定(ding)(ding)系(xi)統(tong)(QS)是(shi)一套快(kuai)速(su)換輥調整系(xi)統(tong),是(shi)MES的(de)重要內容,與(yu)基礎(chu)自(zi)(zi)動(dong)化(hua)(hua)L1相連(lian)接,既向L1發送(song)設(she)定(ding)(ding)數據,又從L1收集各產(chan)品(pin)規格實(shi)際生(sheng)產(chan)調整時(shi)的(de)輥位值(zhi),對(dui)(dui)優化(hua)(hua)的(de)調整設(she)定(ding)(ding)參數進行繼承,作(zuo)為下(xia)次生(sheng)產(chan)的(de)最新設(she)定(ding)(ding)值(zhi)。根(gen)據產(chan)品(pin)理(li)化(hua)(hua)結果判(pan)定(ding)(ding)當(dang)前設(she)置是(shi)否最優化(hua)(hua),并(bing)(bing)選擇是(shi)否覆(fu)蓋原有數據。改變產(chan)品(pin)規格時(shi),通過比較當(dang)前所生(sheng)產(chan)規格與(yu)即將(jiang)生(sheng)產(chan)規格,并(bing)(bing)根(gen)據對(dui)(dui)頭焊(han)縫跟蹤信(xin)息,快(kuai)速(su)設(she)定(ding)(ding)PC自(zi)(zi)動(dong)向PLC 發送(song)軋(ya)輥直(zhi)徑、輸送(song)角、力矩、輥位設(she)定(ding)(ding)值(zhi)、焊(han)接功(gong)率(lv)參考值(zhi)和熱(re)處理(li)溫度設(she)定(ding)(ding)值(zhi)等(deng)。

d. 根據設備提供(gong)的焊接質量跟(gen)蹤系統,以曲線或波形形式顯示當前的焊接速(su)度(du)、焊接溫度(du)、焊接功率、各段熱(re)處理(li)溫度(du)和(he)功率、探傷(shang)缺(que)陷類型等,并存入數據庫供(gong)分析。

e. 基礎自動化控(kong)(kong)制(zhi)(zhi)功能主要包括:自動順序(xu)控(kong)(kong)制(zhi)(zhi)、料流跟蹤(zong)、焊縫位(wei)置跟蹤(zong)、鋼卷對(dui)中控(kong)(kong)制(zhi)(zhi)、開卷機張力控(kong)(kong)制(zhi)(zhi)、活套充套量控(kong)(kong)制(zhi)(zhi)、主傳動速度(du)控(kong)(kong)制(zhi)(zhi)、軋輥位(wei)置控(kong)(kong)制(zhi)(zhi)、銑邊控(kong)(kong)制(zhi)(zhi)、焊接功率控(kong)(kong)制(zhi)(zhi)、熱處理(li)溫(wen)度(du)控(kong)(kong)制(zhi)(zhi)和飛鋸控(kong)(kong)制(zhi)(zhi)等(deng)。

三、技術水(shui)平與(yu)業績(ji)

寶鋼(gang)ф610mm HFW 不銹鋼(gang)焊(han)管(guan)機組憑(ping)借其設備一流(liu),管(guan)理先(xian)進,帶鋼(gang)資源及板管(guan)質(zhi)(zhi)量(liang)(liang)一貫制的優勢(shi),無論(lun)是(shi)產(chan)品品種,規格拓展,還是(shi)在產(chan)量(liang)(liang)、質(zhi)(zhi)量(liang)(liang)及效益方面均取得(de)了國(guo)內同(tong)類機組最好的業績。產(chan)品廣(guang)泛應用于(yu)油(you)氣輸(shu)送、油(you)氣開采、海洋平臺及大型建筑(zhu)物。

自2005年(nian)10月27日投產(chan)以來,依托寶(bao)鋼股份一貫制優勢,寶(bao)鋼HFW不(bu)銹(xiu)鋼焊(han)管(guan)(guan)(guan)已(yi)經(jing)開(kai)發(fa)生(sheng)產(chan)B-X80管(guan)(guan)(guan)線(xian)管(guan)(guan)(guan),Q235-Q500結構及(ji)低壓流體管(guan)(guan)(guan),H40-P110油套管(guan)(guan)(guan)。2006-2018年(nian)累計(ji)供貨HFW 焊(han)管(guan)(guan)(guan)165萬(wan)(wan)噸(2.35萬(wan)(wan)千米),其中(zhong)(zhong)30%的產(chan)品(pin)出口到澳大(da)利(li)亞(ya)(ya)、加(jia)(jia)拿大(da)、南美、中(zhong)(zhong)東(dong)、非洲及(ji)東(dong)南亞(ya)(ya)市場等海外市場。產(chan)品(pin)先后在中(zhong)(zhong)石油長慶三凈(jing)-延電輸氣項(xiang)(xiang)(xiang)目(mu)(mu)、印尼TTU管(guan)(guan)(guan)線(xian)項(xiang)(xiang)(xiang)目(mu)(mu)、中(zhong)(zhong)海油南堡海管(guan)(guan)(guan)項(xiang)(xiang)(xiang)目(mu)(mu)、中(zhong)(zhong)石化塔河油田(tian)抗酸管(guan)(guan)(guan)線(xian),巴西礦漿X70管(guan)(guan)(guan)線(xian)、加(jia)(jia)拿大(da)Nexeng公(gong)司(si)的管(guan)(guan)(guan)線(xian)項(xiang)(xiang)(xiang)目(mu)(mu)、加(jia)(jia)拿大(da)Husky公(gong)司(si)的管(guan)(guan)(guan)線(xian)項(xiang)(xiang)(xiang)目(mu)(mu)、加(jia)(jia)拿大(da)Encana公(gong)司(si)管(guan)(guan)(guan)線(xian)項(xiang)(xiang)(xiang)目(mu)(mu)、澳大(da)利(li)亞(ya)(ya)的APA管(guan)(guan)(guan)線(xian)、澳大(da)利(li)亞(ya)(ya)Jemena和澳大(da)利(li)亞(ya)(ya)DBP等管(guan)(guan)(guan)線(xian)項(xiang)(xiang)(xiang)目(mu)(mu)得到應用。