一(yi)、裝(zhuang)置(zhi)簡介

氯堿(jian)工(gong)業(ye)(ye)(ye)作為(wei)衡量(liang)國家化工(gong)行業(ye)(ye)(ye)發展(zhan)(zhan)的重要指標(biao),廣泛應用于輕工(gong)業(ye)(ye)(ye)、紡織工(gong)業(ye)(ye)(ye)、冶(ye)金工(gong)業(ye)(ye)(ye)、石油化學工(gong)業(ye)(ye)(ye)以(yi)及公(gong)用事業(ye)(ye)(ye)。氯堿(jian)的生(sheng)(sheng)產(chan)工(gong)藝(yi)一般分為(wei)苛化法(fa)、隔膜法(fa)、水銀(yin)法(fa)及離子膜法(fa)。離子膜制(zhi)堿(jian)法(fa)從(cong)20世(shi)紀80年代開(kai)始發展(zhan)(zhan),現已成(cheng)為(wei)我國新建(jian)燒堿(jian)工(gong)廠中(zhong)最廣泛應用的工(gong)藝(yi)。其工(gong)藝(yi)流(liu)程是(shi)通過(guo)電(dian)解食鹽水生(sheng)(sheng)產(chan)燒堿(jian)和氯氣(qi)、氫(qing)氣(qi),產(chan)品作為(wei)其他化工(gong)產(chan)品的生(sheng)(sheng)產(chan)原(yuan)料(liao)。以(yi)下以(yi)離子膜制(zhi)堿(jian)的工(gong)藝(yi)裝置為(wei)例介紹(shao)。

二、離(li)子膜氯(lv)堿(jian)裝置(zhi)的工藝及特點

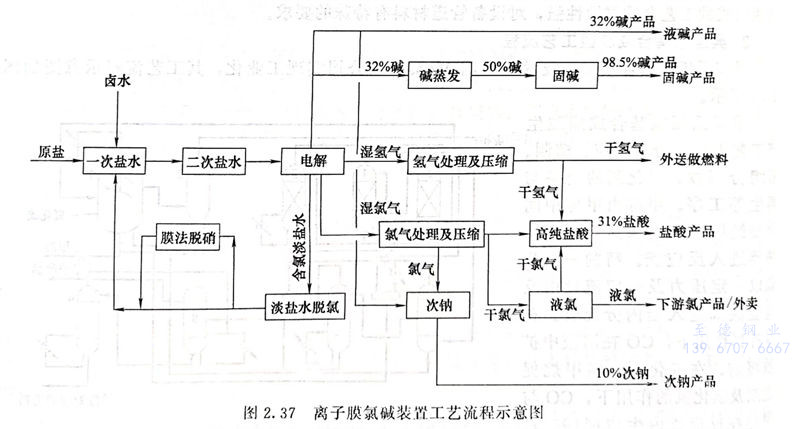

離(li)子(zi)膜氯(lv)堿裝置工藝(yi)流程(cheng)示(shi)意(yi)圖如圖2.37所示(shi)。整個裝置大致可劃分為一次(ci)鹽水和(he)二次(ci)鹽水精制(zhi)、電解單元、淡鹽水脫(tuo)氯(lv)、氫氣(qi)處理及壓縮(suo)(suo)、氯(lv)氣(qi)處理及壓縮(suo)(suo)、氯(lv)氣(qi)液化、鹽酸合(he)成及堿蒸發單元。

以原(yuan)鹽、鹵水(shui)(shui)作為原(yuan)料,通(tong)過(guo)(guo)一次(ci)鹽水(shui)(shui)膜(mo)過(guo)(guo)濾,將鹽水(shui)(shui)中大分子(zi)有機物分解(jie)成小分子(zi),并初(chu)步(bu)去除(chu)。再經(jing)過(guo)(guo)二次(ci)鹽水(shui)(shui)的(de)(de)螯合樹脂(zhi)塔,進一步(bu)除(chu)去其中的(de)(de)鈣、鎂(mei)等金屬離(li)子(zi)及(ji)懸浮物后(hou)。將鹽水(shui)(shui)加入(ru)離(li)子(zi)膜(mo)電(dian)(dian)解(jie)槽(cao)的(de)(de)陽極室(shi),與(yu)此(ci)同(tong)時,純(chun)水(shui)(shui)和(he)堿液(ye)(ye)一同(tong)進入(ru)陰極室(shi)。電(dian)(dian)解(jie)槽(cao)通(tong)入(ru)直流電(dian)(dian)后(hou),在陽極室(shi)產(chan)(chan)生(sheng)氯(lv)氣(qi)(qi)和(he)含氯(lv)淡鹽水(shui)(shui),經(jing)過(guo)(guo)分離(li)器分離(li),氯(lv)氣(qi)(qi)輸送(song)到(dao)氯(lv)氣(qi)(qi)處(chu)理(li)及(ji)壓縮單(dan)元。在電(dian)(dian)解(jie)槽(cao)的(de)(de)陰極室(shi)產(chan)(chan)生(sheng)氫(qing)氣(qi)(qi)和(he)液(ye)(ye)堿。同(tong)樣經(jing)過(guo)(guo)分離(li)器,氫(qing)氣(qi)(qi)輸送(song)到(dao)氫(qing)氣(qi)(qi)處(chu)理(li)及(ji)壓縮單(dan)元,堿液(ye)(ye)可以作為商(shang)品出售,也可以送(song)到(dao)堿蒸發單(dan)元,使其濃(nong)縮成50%的(de)(de)堿液(ye)(ye)。電(dian)(dian)解(jie)產(chan)(chan)生(sheng)的(de)(de)濕氯(lv)氣(qi)(qi)經(jing)過(guo)(guo)洗滌、干燥、壓縮后(hou),送(song)往(wang)下游作為原(yuan)料使用,或通(tong)過(guo)(guo)冷(leng)介(jie)質降溫液(ye)(ye)化(hua),形成液(ye)(ye)氯(lv)存入(ru)儲槽(cao);未(wei)液(ye)(ye)化(hua)的(de)(de)氯(lv)氣(qi)(qi)與(yu)氫(qing)氣(qi)(qi)壓縮單(dan)元過(guo)(guo)來的(de)(de)氫(qing)氣(qi)(qi)用于合成氯(lv)化(hua)氫(qing)氣(qi)(qi)體或鹽酸(suan)。

三、主(zhu)要工藝介(jie)質

氯堿裝置的工藝介質中包含了強酸(如氯氣、氯化氫等)、強堿(如氫氧化鈉等)、氫氣等具有腐蝕性強、易燃爆、有毒有害的介質。其中電解單元的進料鹽水對鑄鐵、碳鋼、不銹(xiu)鋼材料有不同程度的腐蝕。電解后的淡鹽水中存有游離氯等介質,會加劇對設備、管道材料的腐蝕。因此,在鹽水管道中鋼襯膠、鋼襯塑、塑料閥門的運用較為廣泛。裝置的產品氯氣是一種有毒氣體,逸散性強。同時氯的化學性質很活潑,在一定條件下能與很多金屬及非金屬發生反應。尤其在有水的情況下,氯氣與水反應生成鹽酸和次氯酸。次氯酸受熱及光等的作用易分解出初生態氧并生成鹽酸,初生態氧又是一種強氧化劑。因此,在氯堿裝置中濕氯氣、干氯氣及液氯的危害性最大。

四、氯堿裝置的(de)配管設計

主要是對塔、罐(guan)、泵、壓縮機等設備的配(pei)管設計。