金屬(shu)齒(chi)(chi)(chi)形(xing)墊(dian)(dian)(dian)片(pian)(pian)也是(shi)一種實體金屬(shu)墊(dian)(dian)(dian)片(pian)(pian),墊(dian)(dian)(dian)片(pian)(pian)的剖(pou)切(qie)面呈鋸齒(chi)(chi)(chi)形(xing),齒(chi)(chi)(chi)距t=1.5~2mm,齒(chi)(chi)(chi)高h=0.65~0.85mm,齒(chi)(chi)(chi)頂寬(kuan)度c=0.2~0.3mm.在(zai)密(mi)封(feng)面上車削若干個同心圓(yuan),其齒(chi)(chi)(chi)數為(wei)7~16,視墊(dian)(dian)(dian)片(pian)(pian)的規格大小(xiao)而定。金屬(shu)齒(chi)(chi)(chi)形(xing)墊(dian)(dian)(dian)片(pian)(pian)的結構型(xing)式有(you)基(ji)本型(xing)、帶(dai)(dai)外(wai)環型(xing)、帶(dai)(dai)內環型(xing)及帶(dai)(dai)內外(wai)環型(xing)四種,比較(jiao)常見的結構為(wei)基(ji)本型(xing)。由于金屬(shu)齒(chi)(chi)(chi)形(xing)墊(dian)(dian)(dian)片(pian)(pian)密(mi)封(feng)表(biao)面接觸區的V型(xing)肋形(xing)成(cheng)許(xu)多具有(you)壓(ya)差的空間線接觸,所以密(mi)封(feng)可靠,使用(yong)(yong)(yong)周期長(chang)。和一般金屬(shu)墊(dian)(dian)(dian)片(pian)(pian)相比,這種墊(dian)(dian)(dian)片(pian)(pian)需要的壓(ya)緊力(li)較(jiao)小(xiao)。金屬(shu)齒(chi)(chi)(chi)形(xing)墊(dian)(dian)(dian)片(pian)(pian)的缺點是(shi),在(zai)每(mei)次更換墊(dian)(dian)(dian)片(pian)(pian)時(shi),都要對兩法(fa)蘭(lan)(lan)密(mi)封(feng)面進行加工,因而費時(shi)費力(li)。另外(wai),墊(dian)(dian)(dian)片(pian)(pian)使用(yong)(yong)(yong)后容(rong)易在(zai)法(fa)蘭(lan)(lan)密(mi)封(feng)面上留下壓(ya)痕(hen),故(gu)一般用(yong)(yong)(yong)于較(jiao)少拆卸的部位。金屬(shu)齒(chi)(chi)(chi)形(xing)墊(dian)(dian)(dian)片(pian)(pian)適用(yong)(yong)(yong)的公(gong)稱壓(ya)力(li)為(wei)1.6~25.0MPa.

一、金(jin)屬齒形(xing)墊片型式、尺寸與(yu)公差

1. 型(xing)式與尺(chi)寸

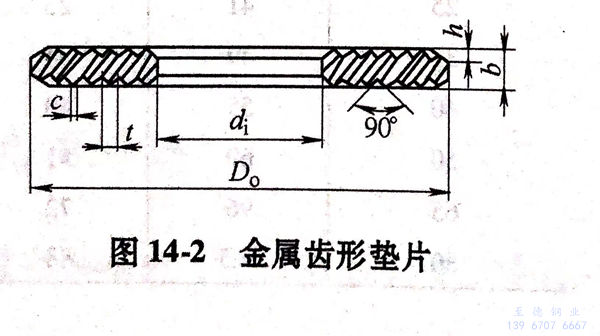

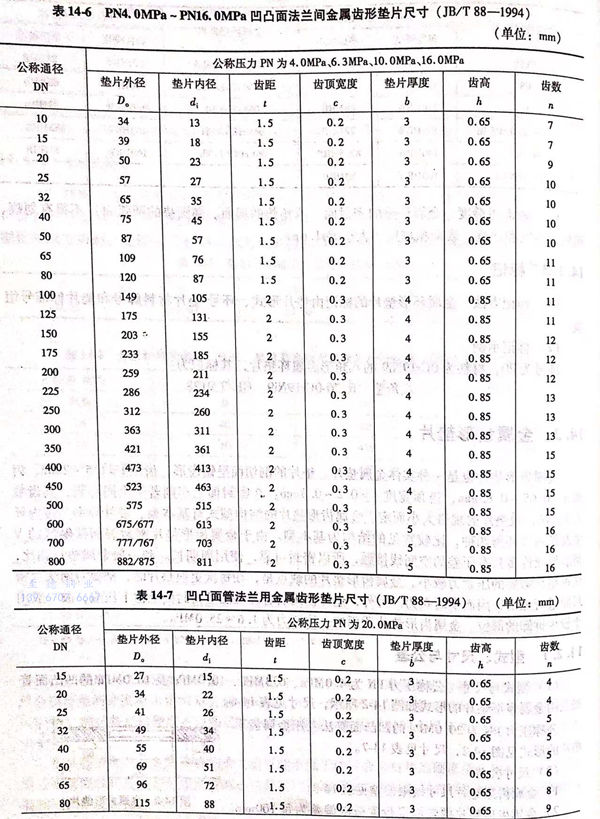

公稱壓力PN為4.0MPa、6.3MPa、10.0MPa及16.0MPa的凹(ao)凸面管(guan)法蘭用(yong)金屬(shu)齒形墊片的形式如圖14-2所示(shi),尺寸見表(biao)14-6。

公稱壓力(li)PN為(wei)20.0MPa的(de)凹凸面管法蘭(lan)用(yong)金屬(shu)齒形墊(dian)片的(de)形式見(jian)圖14-2,尺寸見(jian)表14-7。

2. 尺寸公差

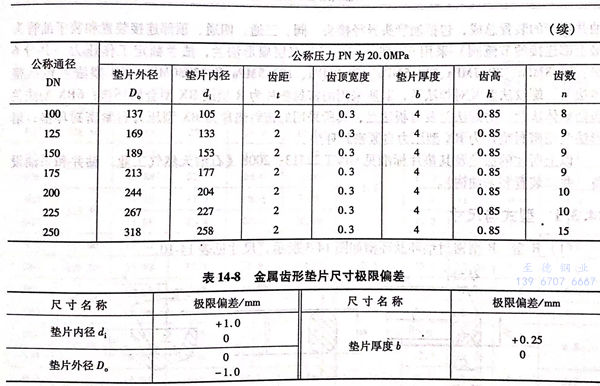

a. 金屬齒(chi)形(xing)墊(dian)片尺寸(cun)極限偏差見表14-8.

b. 金屬齒形墊(dian)片兩(liang)端面平行度極限偏(pian)差為(wei)每(mei)100mm直徑長度不大于(yu)0.1mm。

二、金(jin)屬齒形墊片技術要求

1. 材料

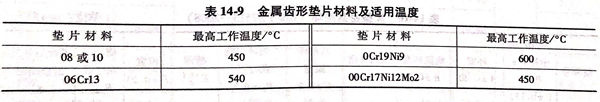

金屬齒(chi)形墊(dian)片(pian)材料及適用的溫(wen)度(du)范圍(wei)見表14-9,材料的其他(ta)技術要(yao)求(qiu)應(ying)符合相應(ying)標準的規定。

2. 表面(mian)粗糙度(du)

金屬齒形墊(dian)片(pian)齒頂平面的(de)表面粗糙度不大(da)于(yu)Ra1.6μm.

三、金(jin)屬齒形墊片標(biao)記

1. 標(biao)記方法

金(jin)屬齒(chi)形墊片(pian)標(biao)記由公(gong)稱通(tong)徑、公(gong)稱壓力、材料(liao)及(ji)標(biao)準編(bian)號等部分組成。

2. 標記示例

公(gong)稱通徑100mm、公(gong)稱壓力(li)6.3MPa、材(cai)料為0Cr19Ni9的凹凸面管法(fa)蘭(lan)用金屬齒(chi)形墊片的標記為: 齒(chi)形墊 100-63 0Cr19Ni9 JB/T 88-1994